Method for making micro-magnetic field integrated polyalcohol microflow control device

A technology of a microfluidic device and a manufacturing method, which is applied in the field of micro-total analysis systems, can solve problems such as high cost, low integration, and complicated processing, and achieve simple processing and manufacturing processes, in-situ integration, and direction controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

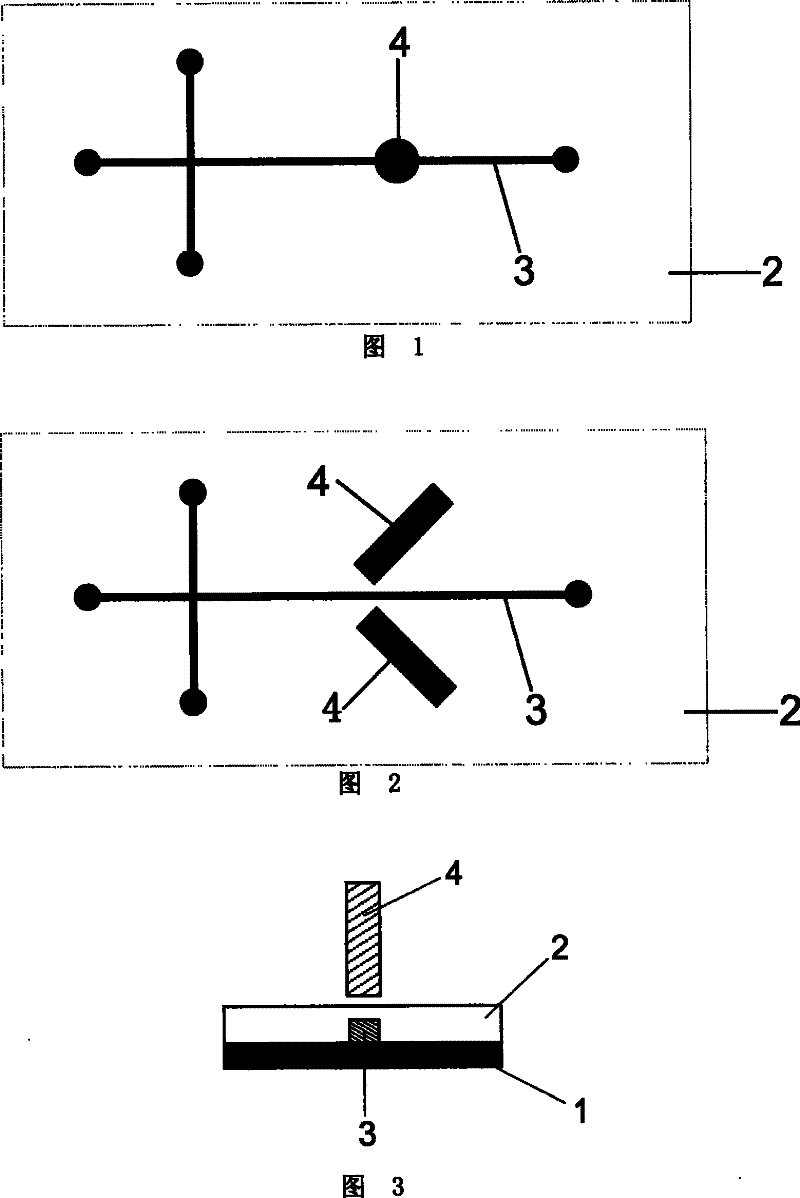

[0026] (1) Prepare the silicon positive mold template for the polydimethylsiloxane microfluidic chip by soft etching;

[0027] (2) winding 40 turns of enamelled copper wire on an iron core with a diameter of 1mm to make a microcoil (4), wherein the diameter of the enamelled copper wire is 0.1mm;

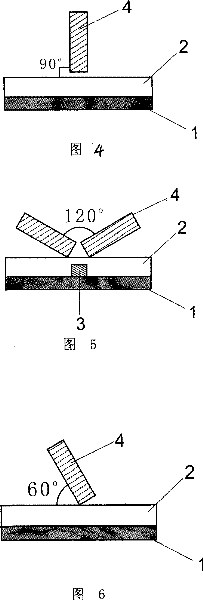

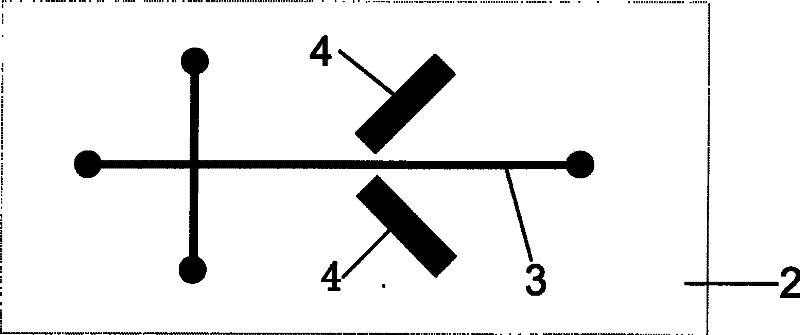

[0028] (3) Two 40-turn microcoils (4) are fixed on both sides of the microchannel on the silicon positive mold template, the angle between the coils is 120°, and the plane formed by the two coils and the plane of the template are clamped. The angle is 60°;

[0029] (4) Mix the polydimethylsiloxane monomer and the curing agent in a ratio of 10:1, stir thoroughly, remove air bubbles and pour it on the silicon positive mold template for fixing the microcoil, and cure at 80°C for 3 hours, Then the cured polydimethylsiloxane is peeled off from the silicon positive mold template to make a chip substrate with microcoils (4) and microchannels (3);

[0030] (5) Punch holes on the chip subst...

Embodiment 2

[0032] (1) A positive glass mold template for the polydimethylsiloxane microfluidic chip is prepared by soft etching;

[0033] (2) Winding 60 turns of enamelled copper wire on an iron core with a diameter of 1.2mm to make a microcoil; wherein the diameter of the enamelled copper wire is 0.1mm;

[0034] (3) Two 60-turn microcoils are fixed on both sides of the microchannel of the glass male template, the angle between the coils is 120°, the plane formed by the two coils and the plane of the glass male template the angle is 90°;

[0035] (4) Mix the polydimethylsiloxane monomer and the curing agent in a ratio of 10:1, stir well, remove air bubbles, pour it on the glass positive mold template for fixing the microcoil, and cure it at 80°C for 3 hours, The cured polydimethylsiloxane is then peeled off from the positive glass template to make a chip substrate with microcoils and microchannels;

[0036] (5) Punch holes on the chip substrate with a puncher, and then treat the surfac...

Embodiment 3

[0038] (1) Prepare the silicon positive mold template for the polydimethylsiloxane microfluidic chip by soft etching;

[0039] (2) Winding 60 turns of enamelled copper wire on an iron core with a diameter of 1.5mm to make a microcoil, wherein the diameter of the enamelled copper wire is 0.1mm;

[0040] (3) Two 60-turn microcoils are fixed on both sides of the microchannel of the silicon positive mold template, the angle between the coils is 60 °, the plane formed by the two coils and the plane of the silicon positive mold template The included angle is 90°;

[0041] (4) Mix the polydimethylsiloxane monomer and the curing agent in a ratio of 10:1, stir well, remove air bubbles and pour it on the chip silicon positive mold template for fixing the microcoil, and cure at 80°C for 3 hours , and then peel off the cured polydimethylsiloxane from the silicon positive mold template to make a chip substrate with microcoils and microchannels;

[0042] (5) Punch holes on the chip substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com