Submerged arc welding carriage

A technology of submerged arc welding and trolley, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc. It can solve the problems of inconvenient adjustment of the position of the control box, inconvenient adjustment of the friction force of the wire reel, and inconvenient adjustment of the angle, etc., to achieve The effect of convenient adjustment, light weight and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

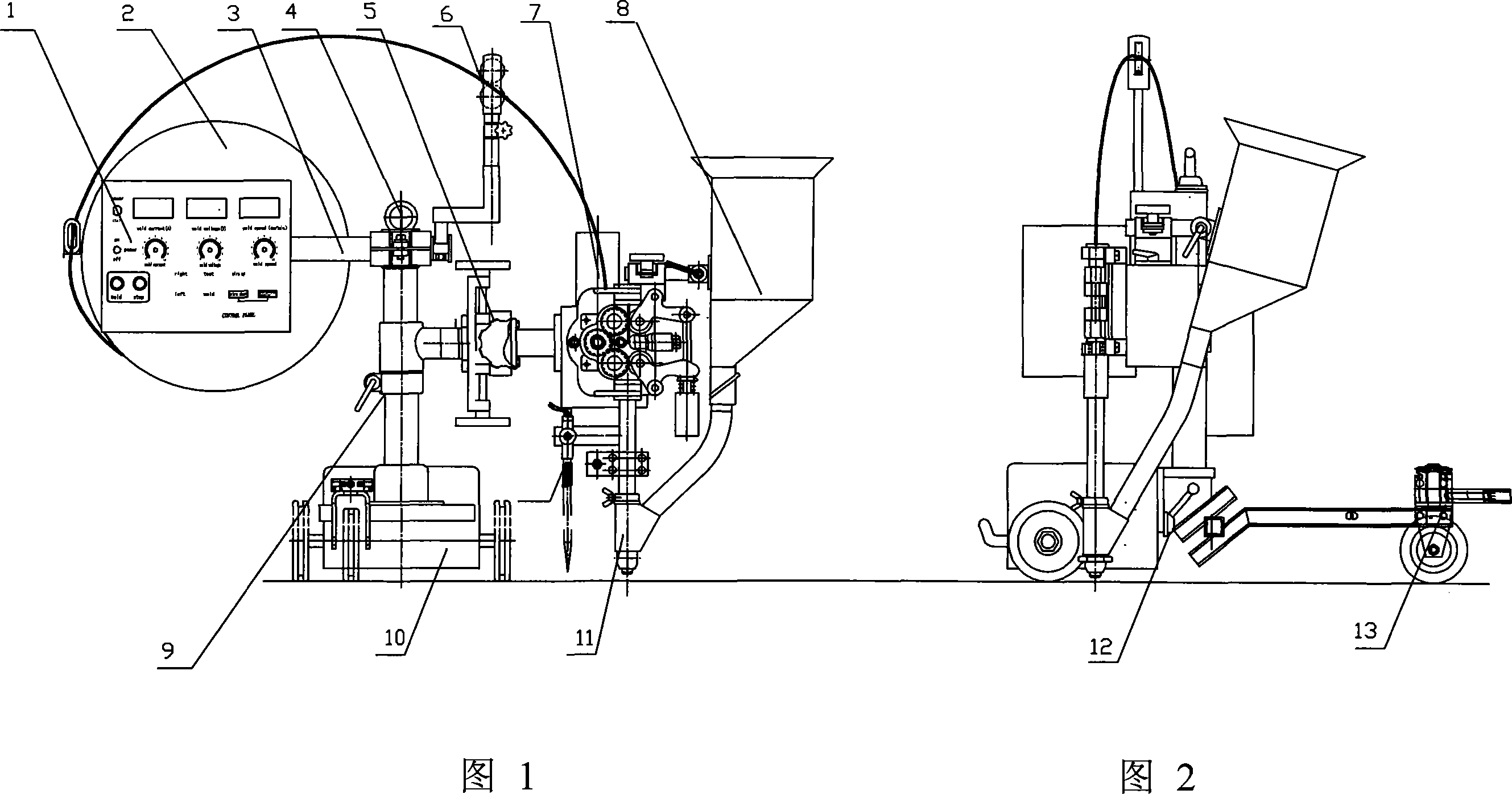

[0018] The present invention mainly consists of a control box 1, a welding wire reel 2, a beam (two pieces) 3, a suspension ring 4, a cross fine-tuning mechanism 5, a wire guide frame 6, a wire feeding mechanism 7, a funnel box 8, a column 9, a walking control box 10, and a funnel Mouth assembly 11, walking clutch 12, fine-tuning mechanism 13 etc. are formed.

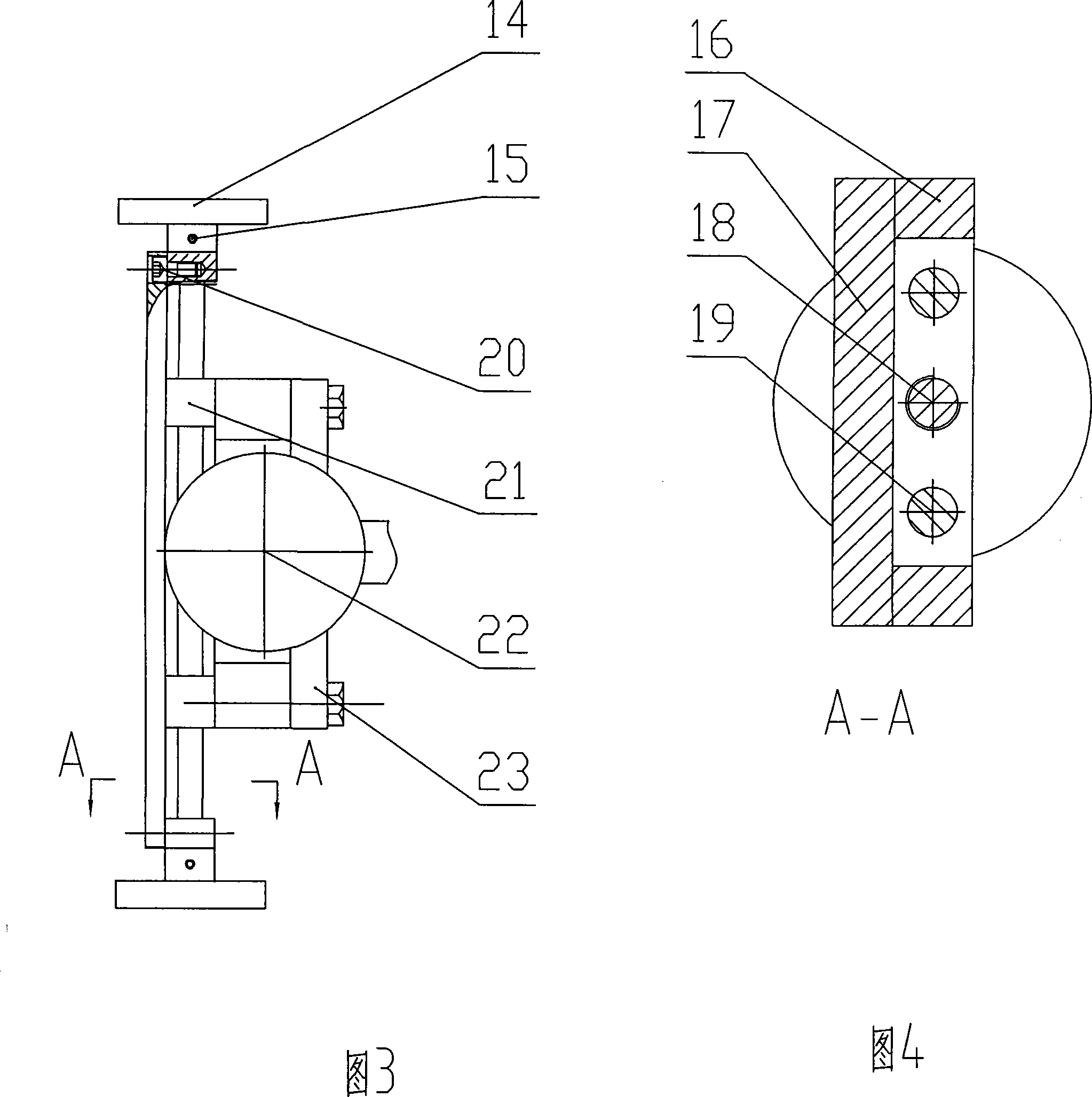

[0019] The cross fine-tuning mechanism 5 is composed of a Y-direction moving assembly, an X-direction moving assembly 22, a wire feeding mechanism connection block 23, and the like.

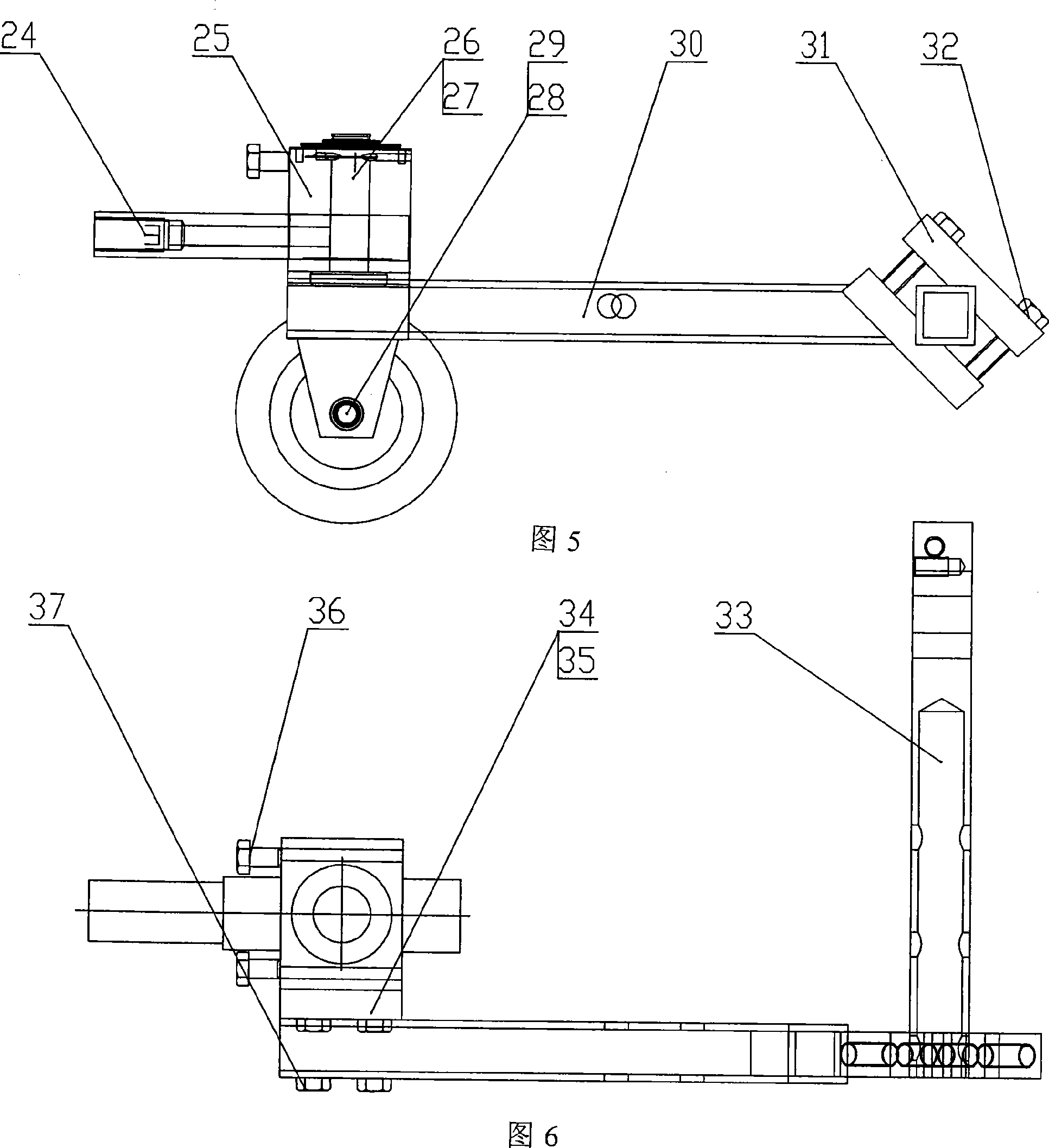

[0020] Described fine-tuning mechanism (guide mechanism) 13 is made of guide handle 24, road wheel mounting bracket 25, road wheel support 26, shaft retaining ring 27, road wheel axle 28, road wheel 29, crossbeam support bar 30, pressing block 31, Screw 32, vertical beam support 33, connecting plate 34, screw 35, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com