Method for extracting validamycin

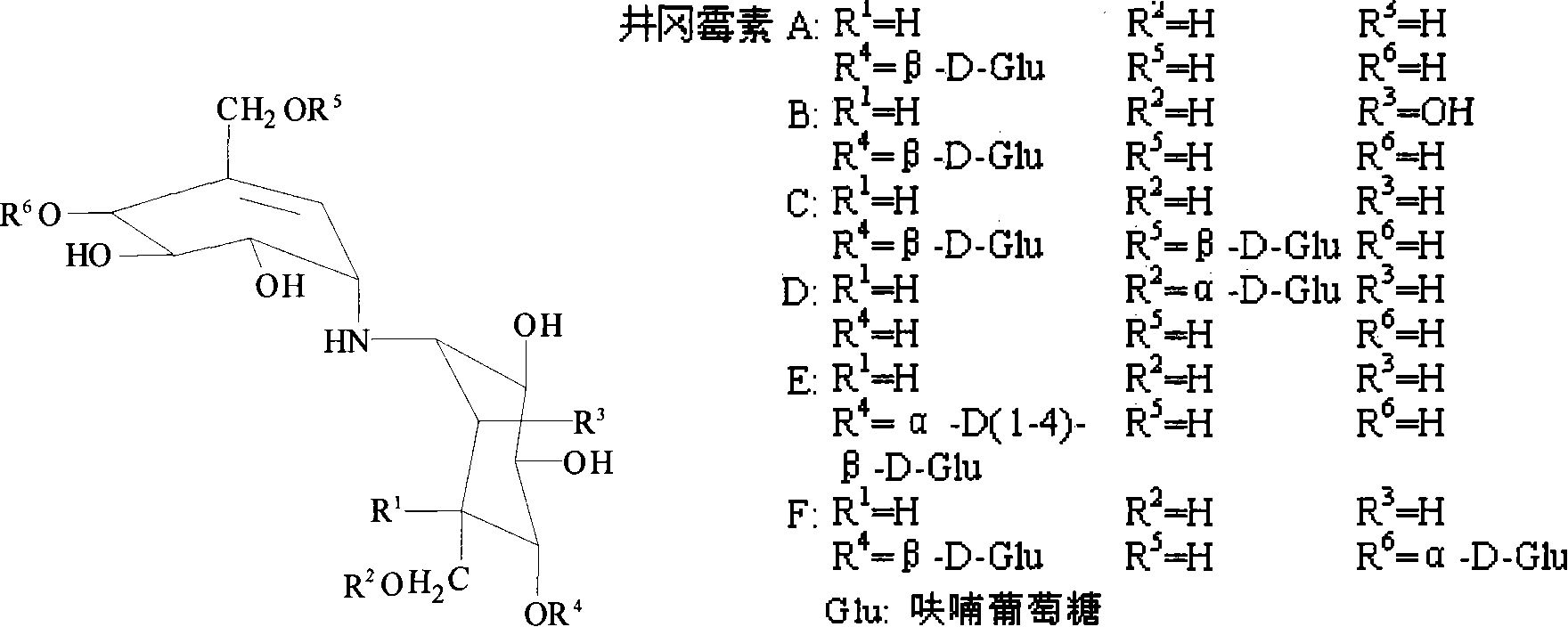

A technology of Jinggangmycin and resin, which is applied in the extraction field of Jinggangmycin, can solve the problems of not meeting the quality requirements of Jinggangmycin products, failing to meet the needs of downstream product development, and being unable to open the international market, etc., achieving low cost and high adsorption capacity. Rapid, easy reprocessing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Fermentation of Jinggangmycin: the strain used is Streptomyces hygroscopicus var. Jinggangensis. Fermentation medium composition (g / l): 90g corn flour, 40g soybean flour, 5g yeast extract, 0.1g K 2 HPO 4 , fermented in a stirred fermenter at a fermentation temperature of 39° C., an aeration rate of 1.0 vvm, and a fermentation time of 45 hours to obtain Jinggangmycin fermentation broth. After analysis, the concentration of Jinggangmycin A in the fermentation broth was 18mg / ml.

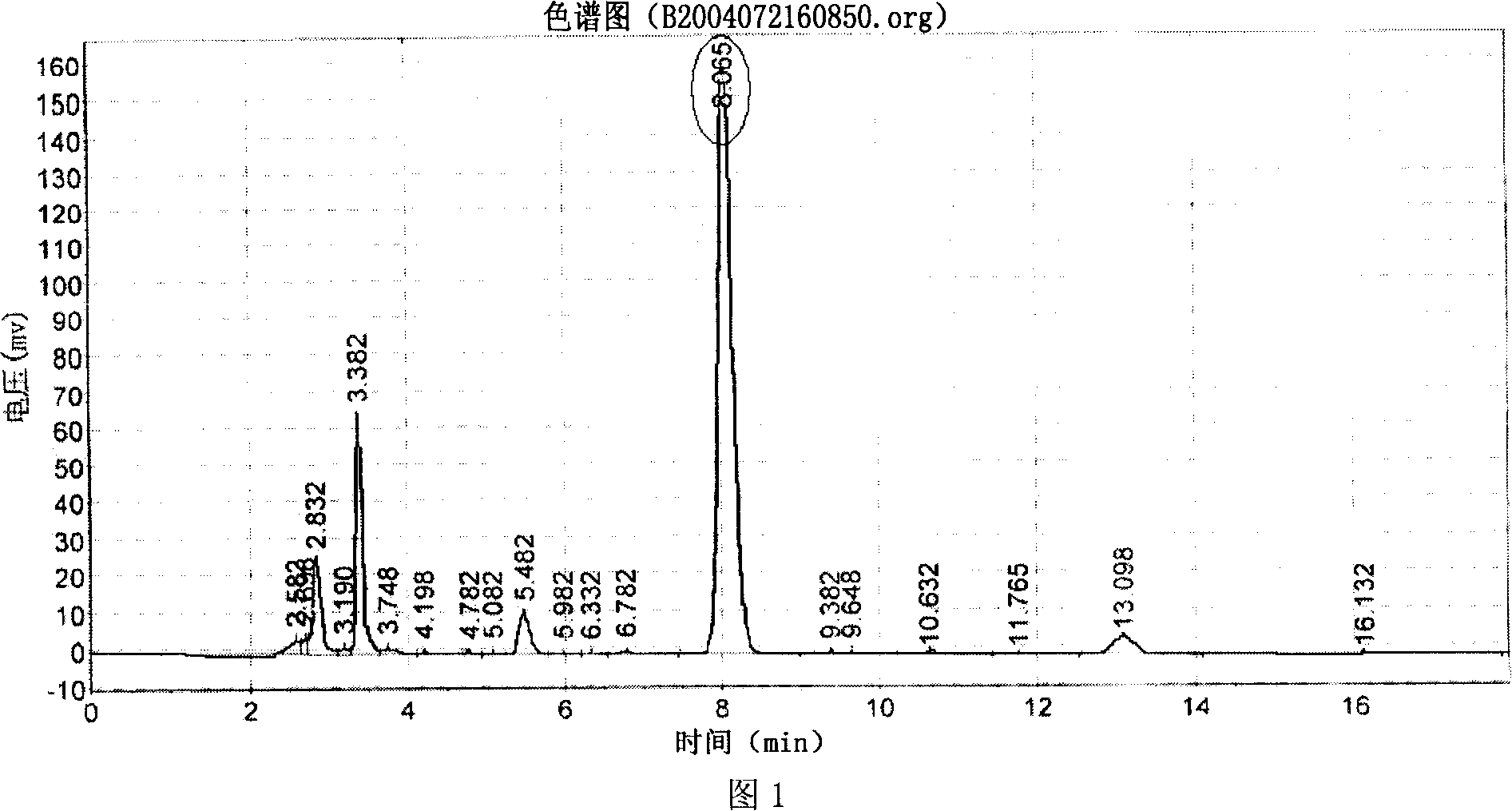

[0045] Take 10L of fermented fermentation broth and heat it to 120°C, keep it for 15 minutes, and filter. The filtrate was passed through MN-500 super large network cation adsorption resin (HYPERSOL-MACRONET TM , Piao Laite China Company) for ion exchange and adsorption, the flow rate is: 1.0m 3 / m 3 Resin·h, until the resin is adsorbed and saturated (detected by high performance liquid chromatography while eluting, and stop adding the filtrate when the saturation point is reached). Then wa...

Embodiment 2

[0048] The fermentation liquid preparation method of Jinggangmycin is the same as embodiment 1

[0049] Take 10L of fermented fermentation broth and heat it to 100°C, keep it for 45 minutes, and filter. The filtrate was passed through MN-500 super large network cation adsorption resin (HYPERSOL-MACRONET TM , Piao Laite China Company) for ion exchange and adsorption, the flow rate is: 1.0m 3 / m 3 Resin·h, until the resin is adsorbed and saturated (detected by high performance liquid chromatography while eluting, and stop adding the filtrate when the saturation point is reached). Then wash the resin with deionized water twice the volume of the resin, and the washing speed is 10m 3 / m 3 Resin h. After washing, use the aqueous ammonia solution of 0.5mol / L as eluent, and elute to the end point according to conventional methods (use high-performance liquid chromatography to detect while eluting, and stop adding eluent when reaching the end point), and the elution rate is 1.0m ...

Embodiment 3

[0051] The fermentation of Jinggangmycin is the same as in Example 1

[0052] Take 10L of fermented fermentation broth and heat it to 120°C, keep it for 15 minutes, and filter. The filtrate passes through C104E resin for ion exchange and adsorption, the flow rate is: 1.0m 3 / m 3 Resin·h, until the resin is adsorbed and saturated (detected by high performance liquid chromatography while eluting, and stop adding the filtrate when the saturation point is reached). Then wash the resin with deionized water twice the volume of the resin, and the washing speed is 3m 3 / m 3 Resin h. After washing, use the aqueous ammonia solution of 1.5mol / L as the eluent, and elute to the end point according to conventional methods (use high-performance liquid chromatography to detect while eluting, and stop adding eluent when reaching the end point), and the elution rate is 1.0m 3 / m 3 Resin h. The eluate obtained was collected, evaporated and concentrated under reduced pressure, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com