Drinking machine without secondary pollution and drinking water barrel matched with the same and working method thereof

A secondary pollution and water dispenser technology, which is applied in the field of water dispensers, can solve problems such as secondary pollution of drinking fountains, and achieve the effects of avoiding secondary pollution, eliminating secondary pollution, and stabilizing water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

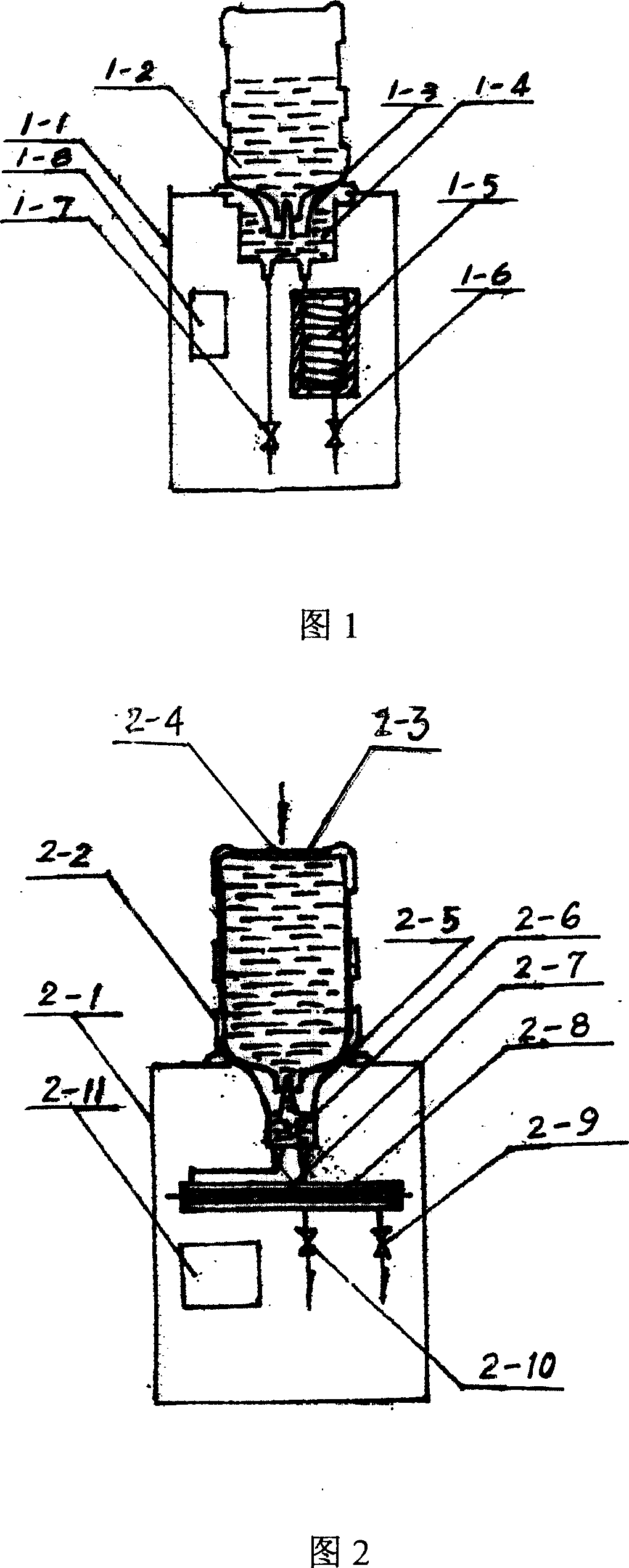

[0029] Embodiment: a water dispenser without secondary pollution (see Fig. 2), which includes a water dispenser body 2-1, a smart seat 2-5 and an electrical control device 2-11, and is characterized in that there is a storage tank at the smart seat 2-5 The water distributor 2-6, the inlet of the water storage distributor 2-6 is directly connected to the bucket mouth, the outlet of the water storage distributor 2-6 is respectively connected to the direct heating electric water heater 2-7 and the cold water cut-off gate 2-10, and the direct heating electric water heater The direct heating electric heating element 2-8 is housed in the 2-7, and the water outlet end of the direct heating electric water heater 2-7 is connected with a hot water shut-off door 2-9.

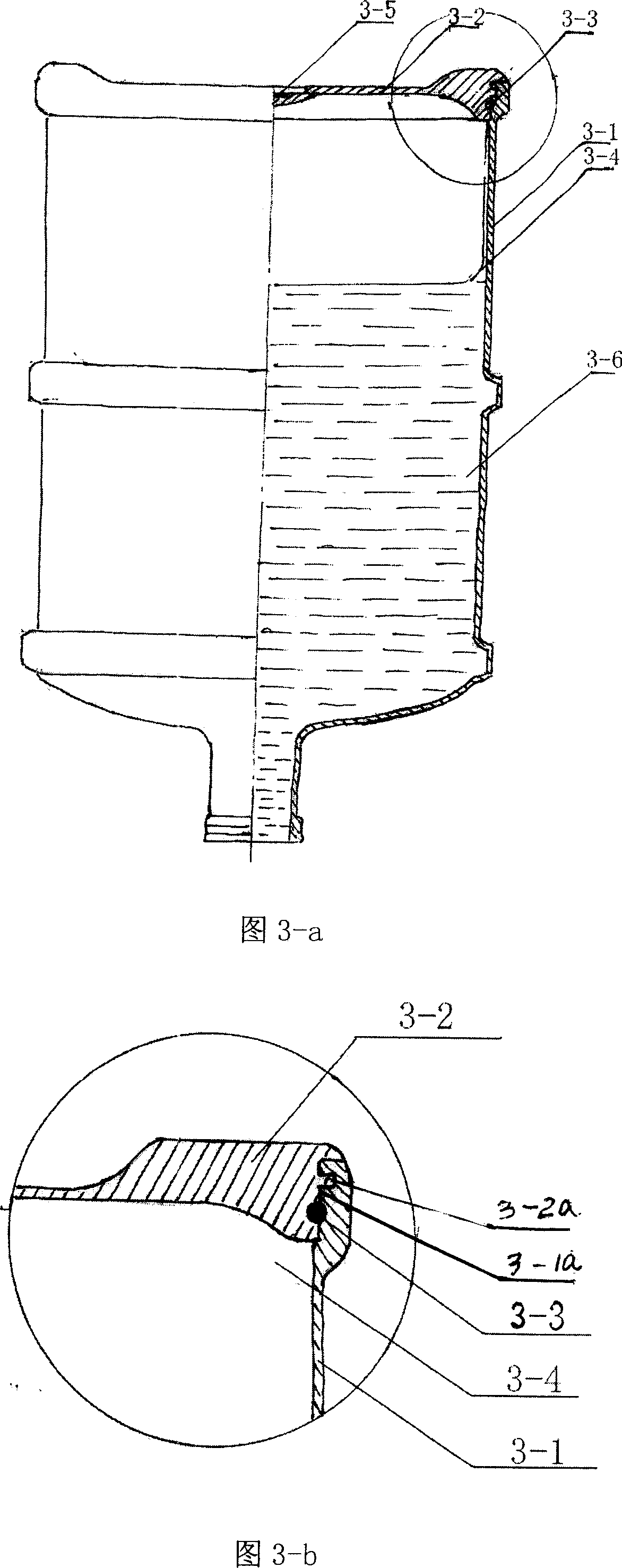

[0030] A drinking water bucket (see Figure 3-ab) for a water dispenser without secondary pollution, which includes a bucket body 3-1, a bucket bottom cover 3-2, a gas storage membrane liner 3-4 and a sealing rubber ring 3- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com