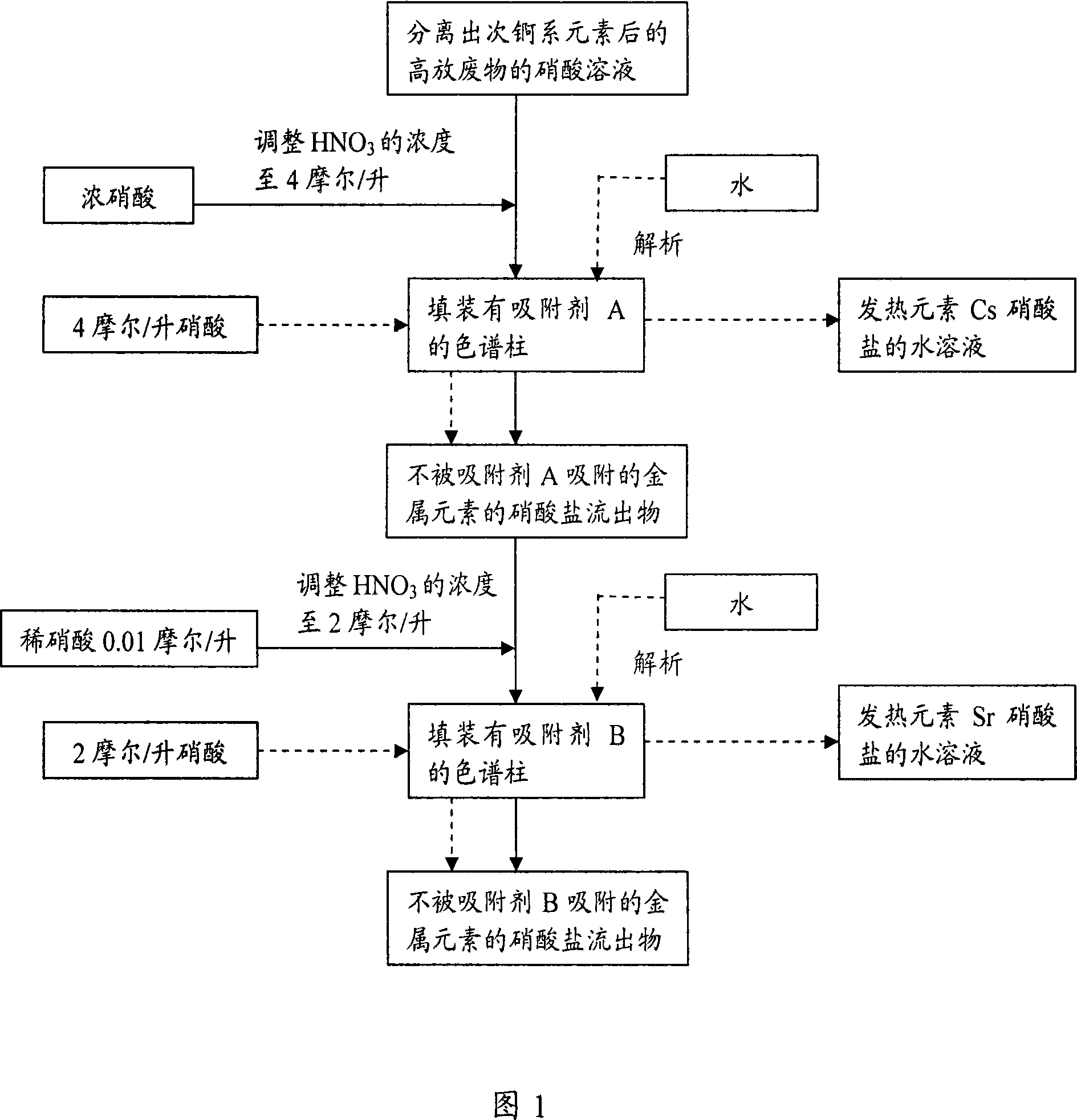

Method for separating heating element Cs and Sr from high radioactive waste

A technology of high-level radioactive waste and elements, which is applied in the field of reprocessing of high-level radioactive waste in the nuclear industry, to achieve safe and effective treatment and disposal, good separation effect and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

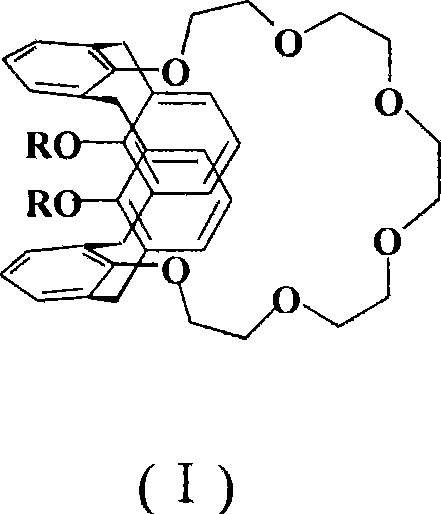

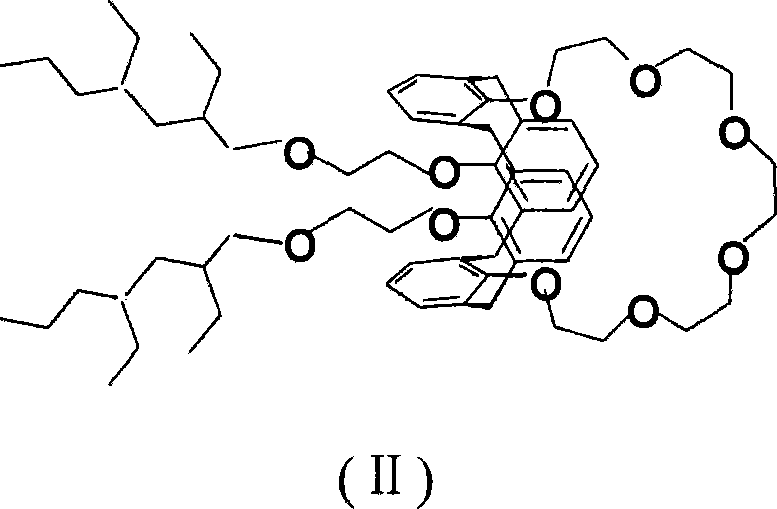

[0050] The preparation of embodiment 1 adsorbent A

[0051] Dissolve 100 g of Calix[4]arene-R14 (with structural formula (II)) and 60 g of tributylphosphate (TBP) in 500 mL of dichloromethane and mix well; add 200 g of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 2

[0052] Example 2 Preparation of Adsorbent A

[0053] Dissolve 100 g of Calix[4]arene-R14 (with structural formula (II)) and 40 g of tributylphosphate (TBP) in 2000 mL of dichloromethane and mix well; add 1000 g of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

Embodiment 3

[0054] Example 3 Preparation of Adsorbent A

[0055] Dissolve 100 g of Calix[4]arene-R14 (with structural formula (II)) and 100 g of tributyl phosphate (TBP) in 3000 mL of dichloromethane and mix well; add 1500 g of polymer-coated macroporous SiO 2 (SiO 2 -P) Stir evenly to volatilize most of the dichloromethane until the material is in a nearly dry state, and then vacuum-dry the nearly dry material at 45° C. for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com