Full-automatic microhardness measuring system

A microhardness and measurement system technology, which is applied in the direction of measuring devices, test material hardness, instruments, etc., can solve the problems of low stability and repeatability of measurement results, cumbersome operation process, and low measurement efficiency. To achieve the effect of overcoming errors, simplifying the process and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

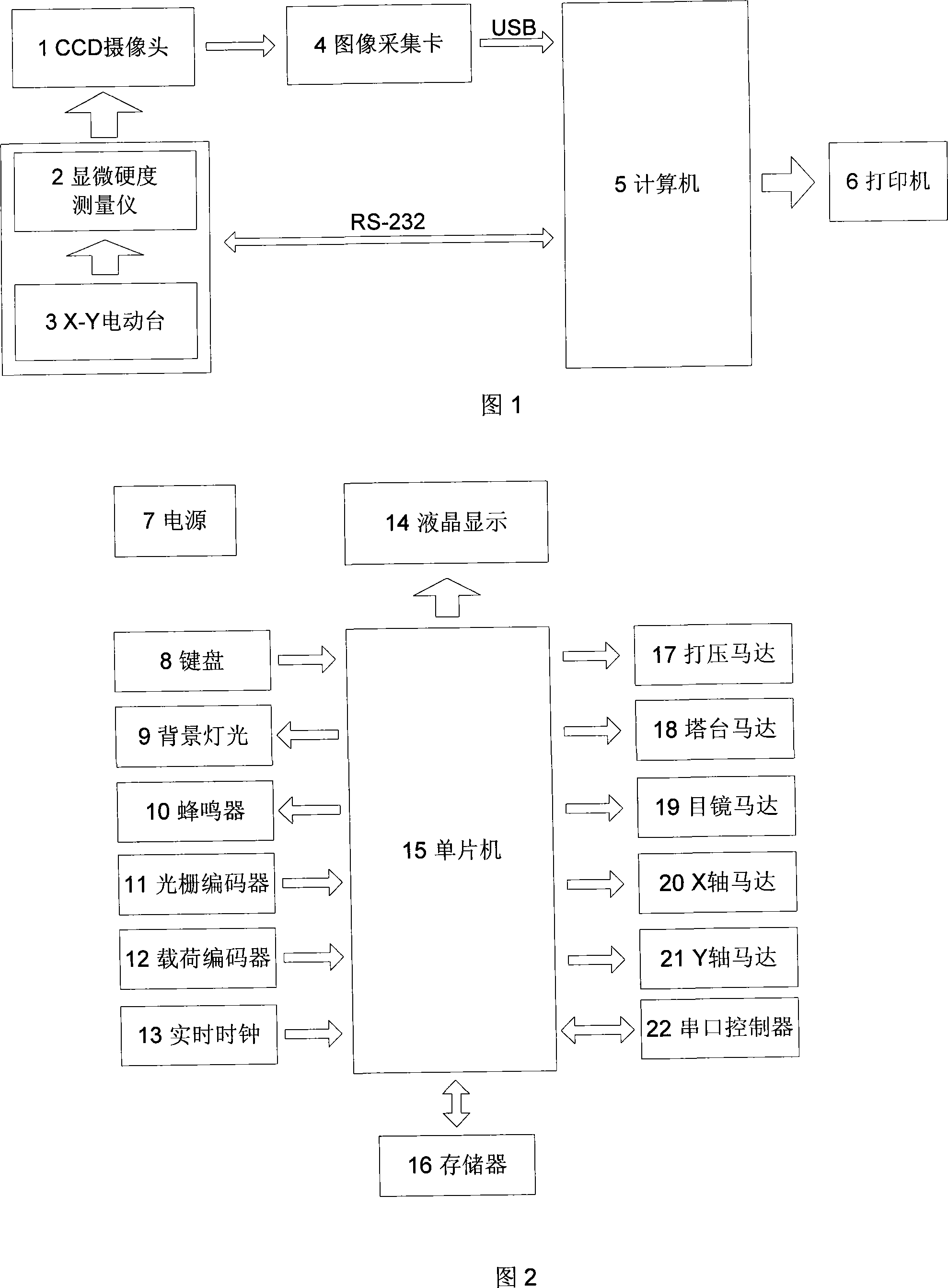

[0028] The automatic microhardness measurement system is mainly composed of microhardness tester, CCD camera, USB image acquisition card, computer, printer, X-Y electric table and special computer software, as shown in Figure 1.

[0029] 1. Hardware part

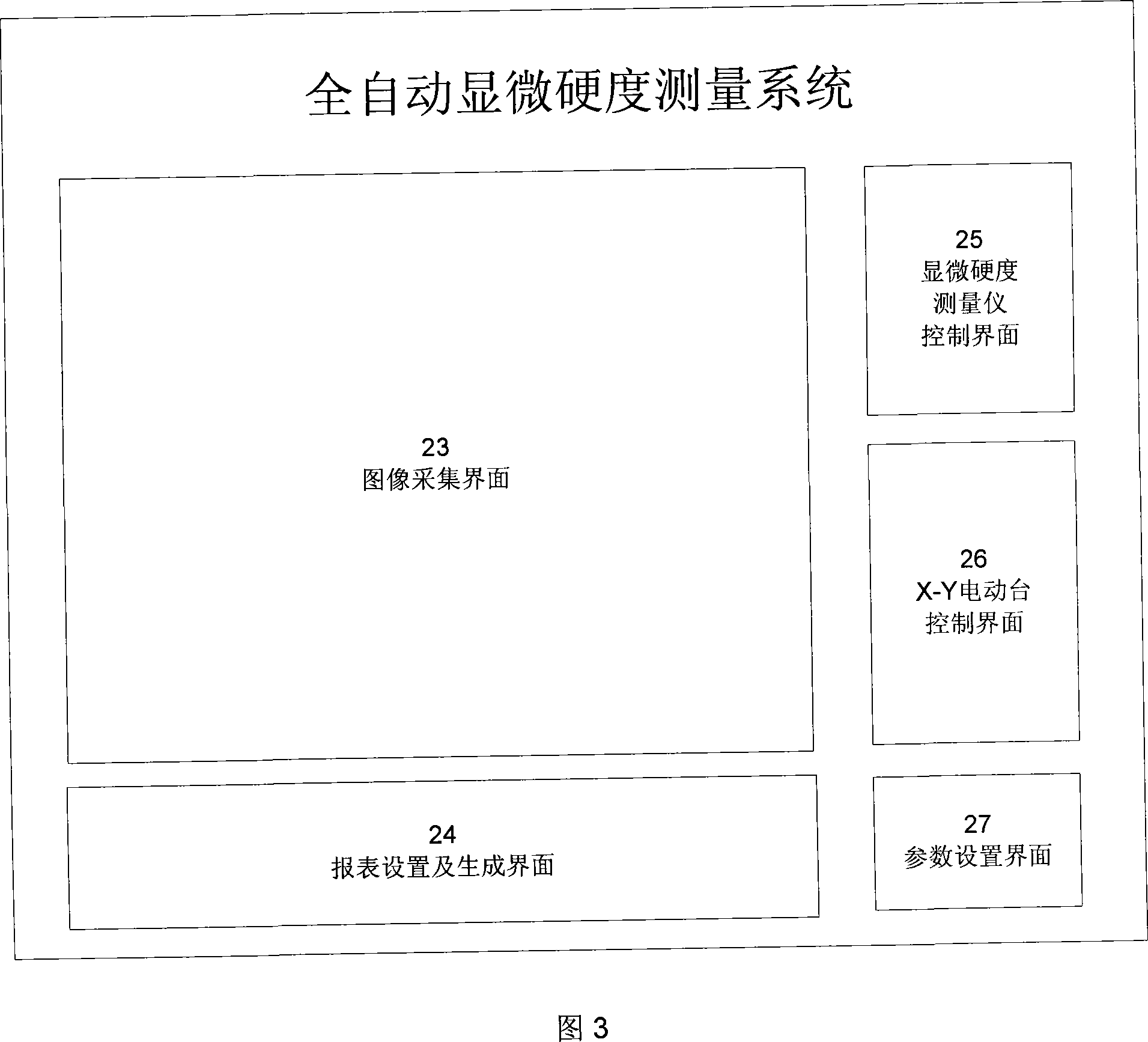

[0030] The microhardness measuring instrument uses Winbond's W78E365 single-chip microcomputer as the core control part, the turret motor and the pressing motor both use the ULN2004 drive chip, the storage chip uses the AT24C16 with the I2C interface, the real-time clock chip uses the DS1302, and the RS-232 interface uses the MAX232 chip. The bus buffer chip mainly uses a three-state latch 74HC573, and the orthogonal signal output by the grating encoder uses a D flip-flop CD401 3 to separate forward and reverse pulse signals. YF62L. W78E365 drives the turret motor to switch between different objective lenses (10x, 40x) and indenters, controls the loading and unloading of the indenter motor, and keeps the load according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com