Compressed air engine electrically driven whole-variable valve actuating system

An electric drive and compressed air technology, which is applied to engine components, variable displacement engines, machines/engines, etc., can solve the problems of large liquid inertia force, high machining accuracy, and complex structure of the electro-hydraulic variable valve system, and achieve structural Simple, achieve recycling, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

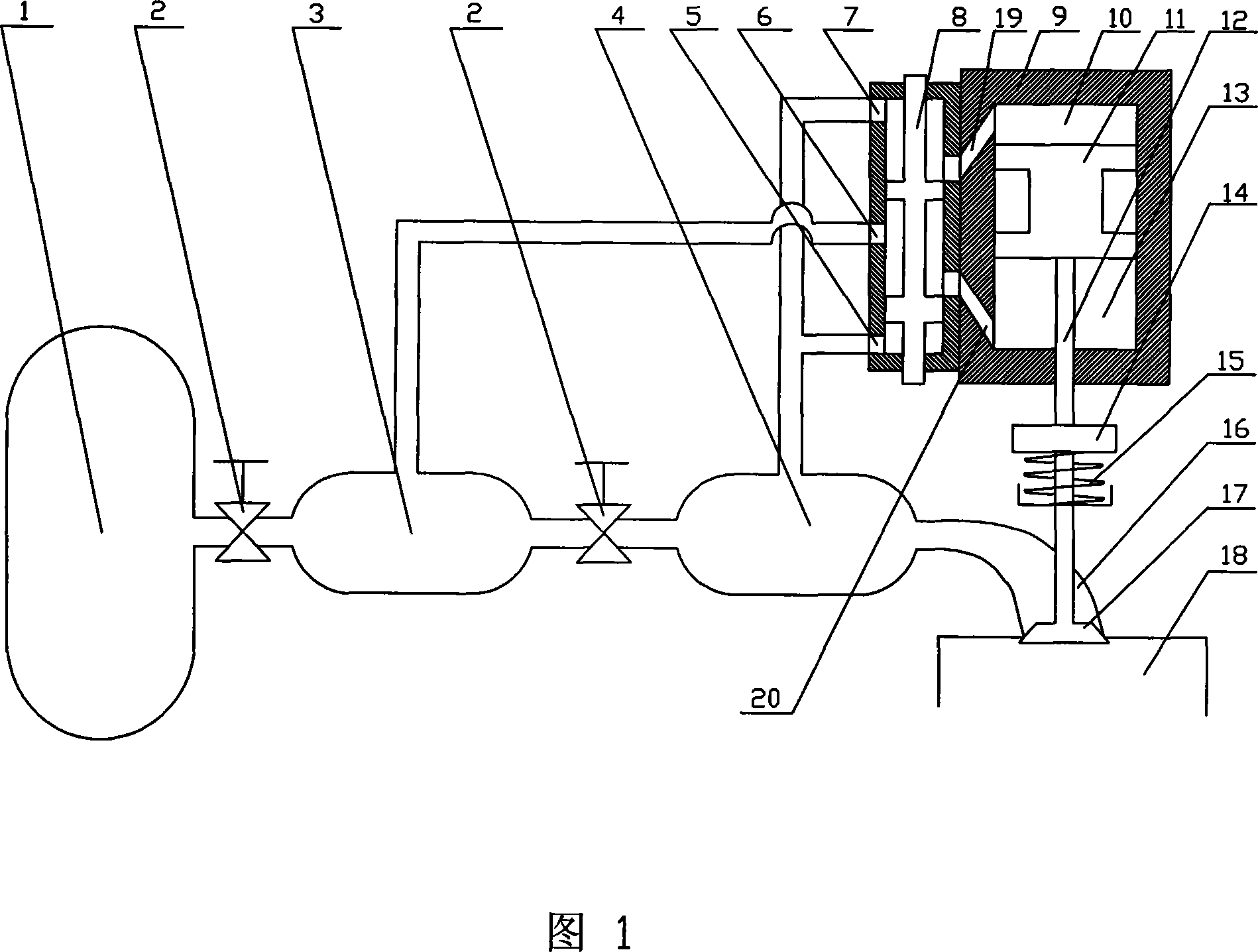

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] In the present embodiment, the electrically driven full variable valve drive system of the compressed air engine is shown in Figure 1, comprising a high-pressure gas storage tank 1, a pressure-stabilizing tank 4 (secondary decompression gas tank) and a valve 17 positioned on a cylinder 18, stabilizing The pressure box 4 is connected to the cylinder 18 through the intake manifold 16, and the valve 17 is connected to the valve spring 15, the coupling 14, the piston rod 12 and the piston 11 in sequence, so the opening and closing movement of the valve 17 is through the reciprocating movement of the piston 11. exercise to achieve.

[0017] The piston 11 is located in the control cylinder 9, and divides the inner chamber of the control cylinder 9 into an upper working chamber 10 and a lower working chamber 13, and the upper working chamber 10 and the lower working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com