Steel lining fluoroplastic alloy self-suction pump

A fluoroplastic, self-priming pump technology, used in pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of long self-priming time and poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

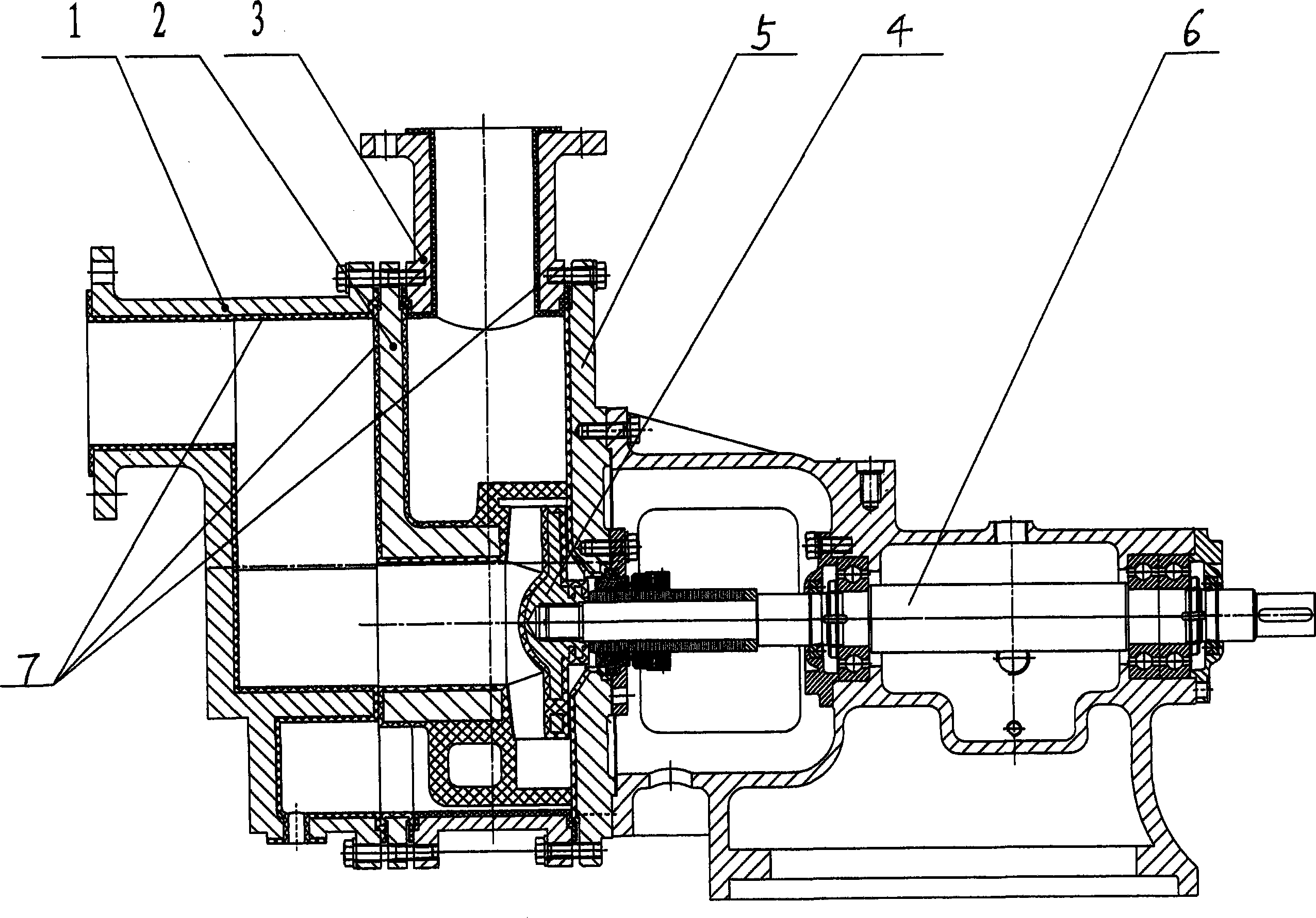

[0009] It can be seen from the drawings that this kind of steel-lined fluoroplastic alloy self-priming pump includes an impeller 4, a pump shaft 6, a rear cover 5 and a pump body. As a result, the suction chamber 1, the volute 2, and the extrusion chamber 3 are tightly connected with each other, and the extrusion chamber 3 is tightly connected with the rear cover 5. The surfaces of the suction chamber 1, the volute 2 and the extrusion chamber 3 are lined with a fluoroplastic structural layer 7, and the thickness of the fluoroplastic structural layer 7 is 4-6mm. The suction chamber 1, the volute 2, and the discharge chamber 3 are assembled after sintering and compression molding respectively, and can be connected and fixed with each other by fasteners such as bolts. Due to the steel-lined fluoroplastic structure of the pump, the volume of the liquid storage chamber (suction chamber, pressure discharge chamber) can be designed to be optimal under the premise of ensuring the stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com