Non-metal reinforcement member

A non-metallic reinforcement and reinforcement technology, applied in electrical components, conductors, insulated cables, etc., can solve the problems of increasing the outer diameter of the optical cable, increasing the consumption of optical cable materials, etc., to ensure tensile performance, weight reduction, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

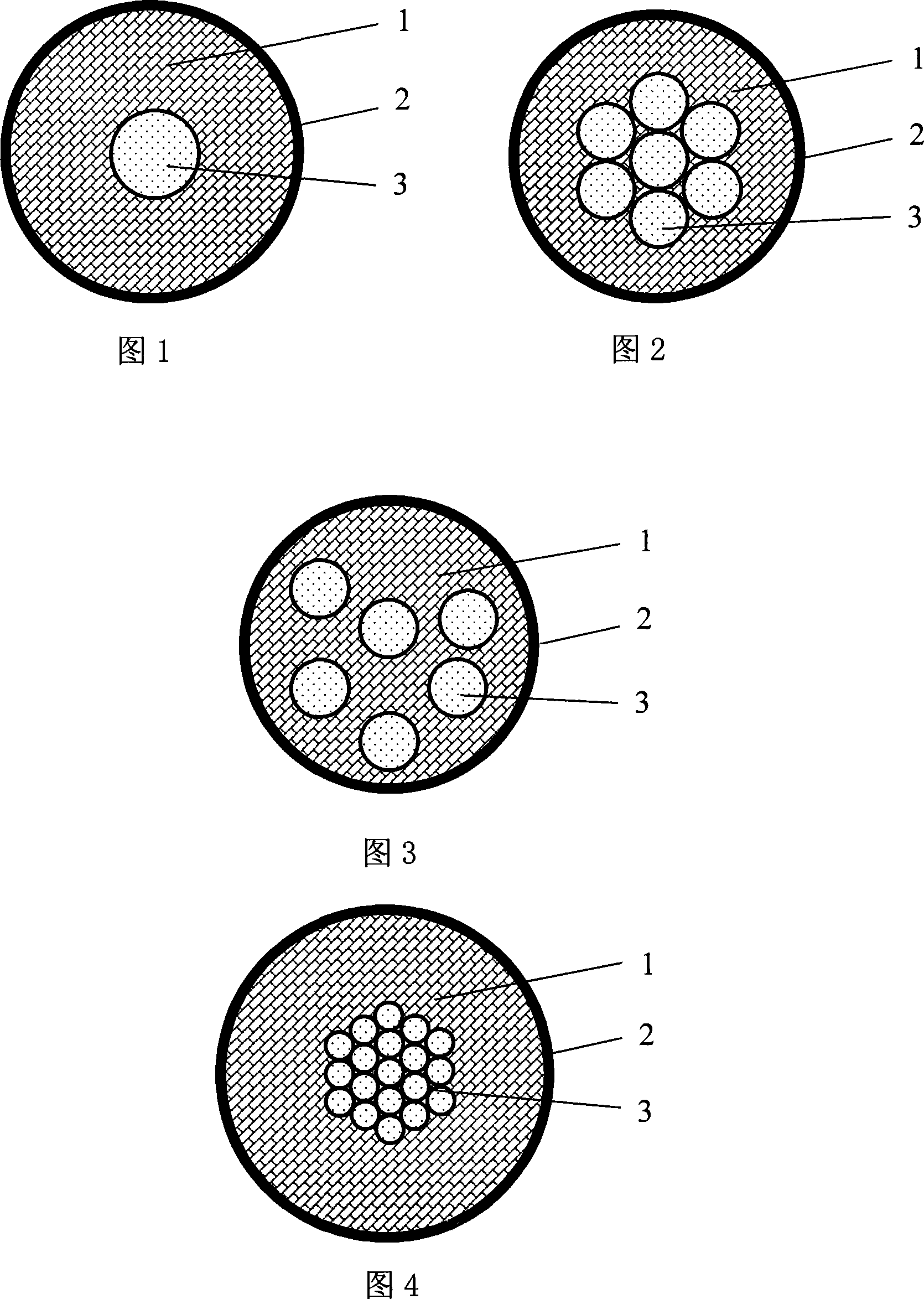

[0019] See Figure 1 for details. In the figure, 1 is the bonding layer, 2 is the extruded layer, and 3 is the high-strength yarn. Among them, the high-strength yarn 3 and the bonding layer 1 are distributed in the extruded layer 2, the high-strength yarn 3 is distributed between the bonding layers 1, the cross-section of the entire reinforcing member is circular, and the high-strength yarn 3 adopts a single-strand aromatic Lun yarn, the outer diameter of which is 0.3mm, the thickness of the extruded layer is 0.85mm, and the outer diameter of the entire reinforcement is 2.0mm. Adhesive layer 1 is made of 0.3mm-2.1mm long glass fiber, adhesive and hot melt adhesive; the adhesive is synthetic resin type, the material of extruded layer 2 is natural color medium density polyethylene, high-strength yarn 3 Located in the center of extruded layer 2.

[0020] Of course, the bonding layer 1 can be bonded by 0.001mm-5mm long glass fibers, adhesives, and hot-melt adhesives; adhesives, ac...

Embodiment 2

[0027] Referring to Fig. 2 for details, it is basically the same as embodiment 1, except that the high-strength yarn 3 in this embodiment is twisted into an aramid rope by 7 shares of aramid yarn, and its strength is higher.

Embodiment 3

[0029] Referring to Fig. 3 for details, it is basically the same as embodiment 1, except that the high-strength yarn 3 in this embodiment is dispersed and distributed in the extrusion layer 2 by 6 strands of glass fiber filaments, and its strength is higher.

[0030] Of course, if there are 2 or more glass fiber filaments, aramid yarns, PBO (poly-p-phenylene benzobisoxazole fibers) or the above two or more mixed yarns distributed in the extruded layer 2, it is also possible Should be the protection scope of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com