Multiple fission copper or aluminum busbar

A multi-split, aluminum busbar technology, used in rubber insulators, plastic/resin/wax insulators, organic insulators, etc., can solve the problem that the actual use of copper-aluminum tube busbars cannot be realized, metal-to-metal welding and compounding, and busbar insulation treatment cannot be realized. Mechanized production and other issues, to achieve the effect of saving non-ferrous metals, light weight and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

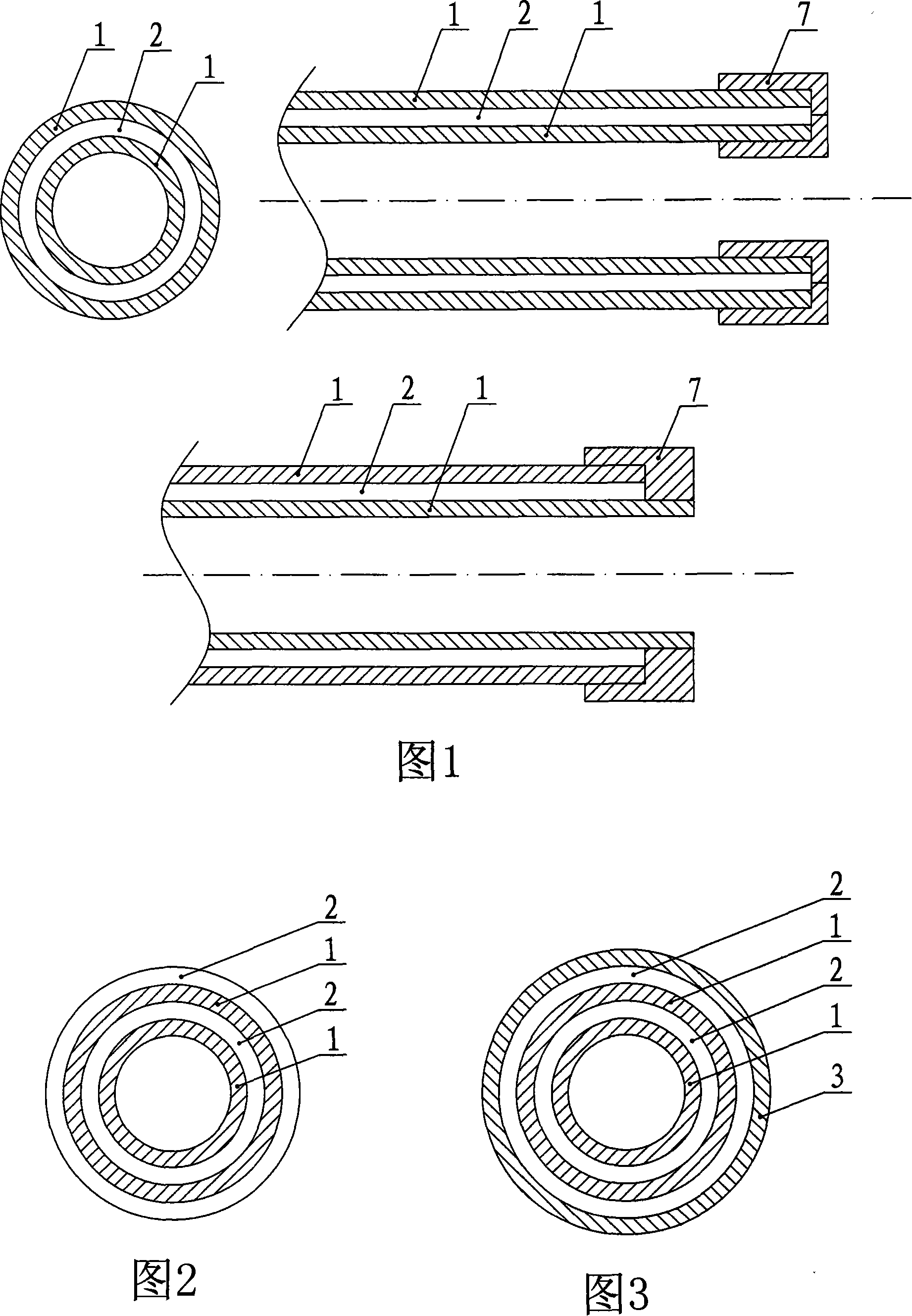

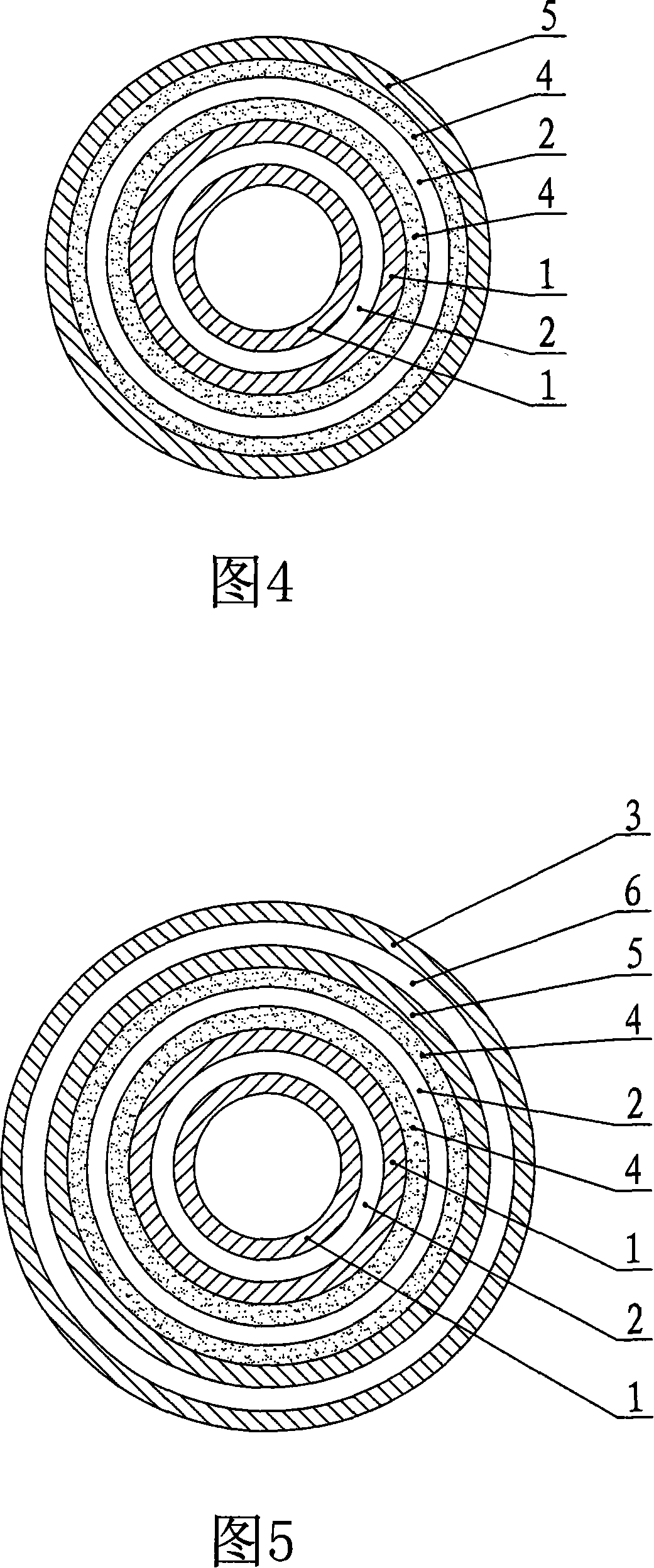

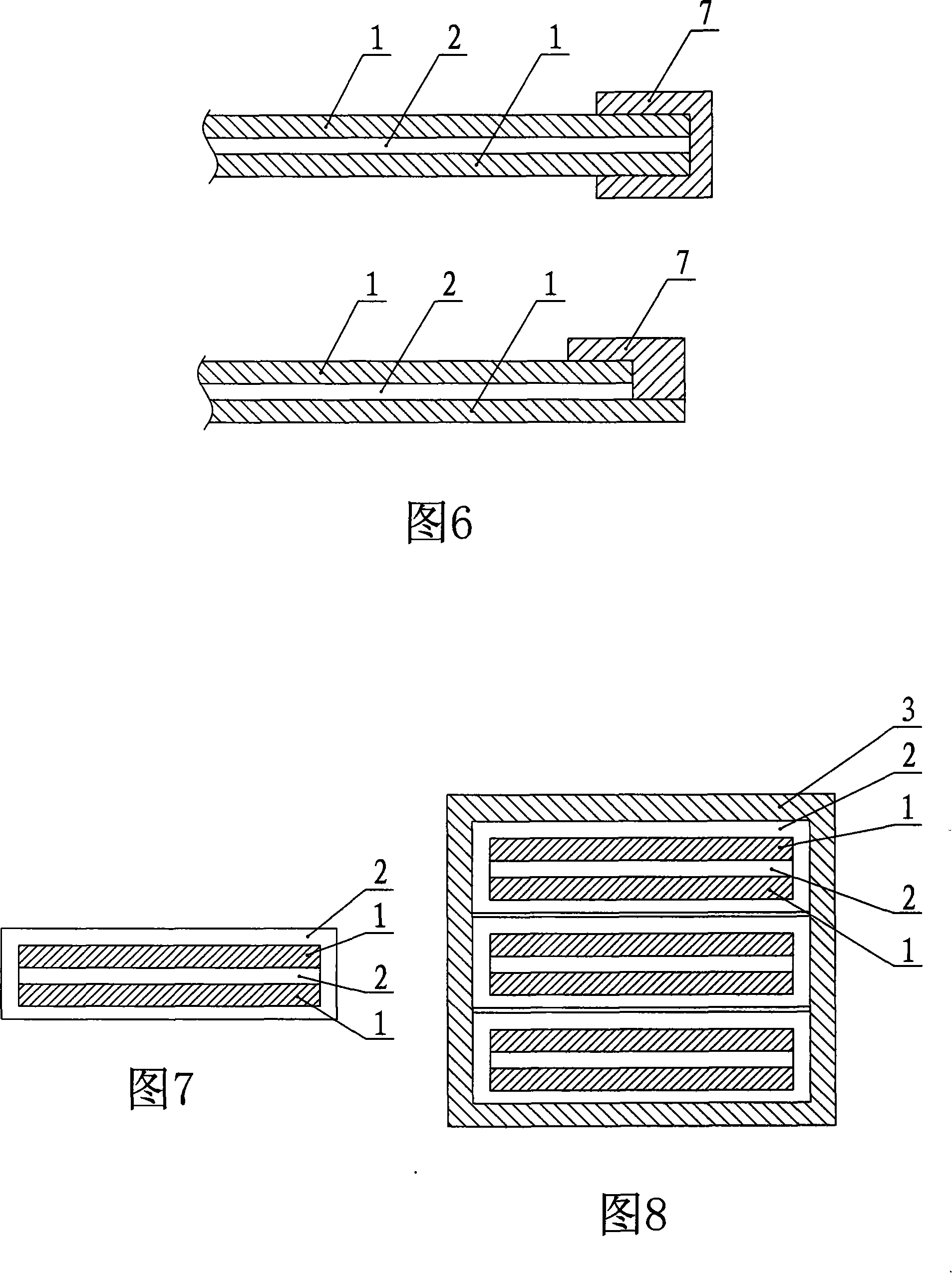

[0031] 1. As shown in Figure 1, the multi-split copper or aluminum busbar (pipe busbar) adopts multi-split conductors, and there is an insulating layer between the conductors, and each conductor has two conductive surfaces.

[0032] Example: ①The rated current is 3150A, the wall thickness of the copper pipe bus conductor is 3mm, and it is composed of two layers of 1.5mm conductors. There is an insulating layer between the conductors and the conductors. Diameter 90mm, cross-sectional area 820mm 2 , weight 7.3kg per meter, current density: 3.8(A / mm 2 ), temperature rise 40k.

[0033] Its (pipe bus) manufacturing method: according to the current carrying capacity requirements, select the appropriate thin copper or aluminum plate (thickness 0.1mm ~ 5mm), use the welded pipe production line to produce copper or aluminum pipes first, and then insulate the copper or aluminum pipes Treatment (according to the requirements of operating temperature, the selection of insulating materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com