Multi-chip light emitting diode module group structure and method of producing the same

A technology of light-emitting diode and module structure, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., to solve the problem of centralized heat dissipation and improve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

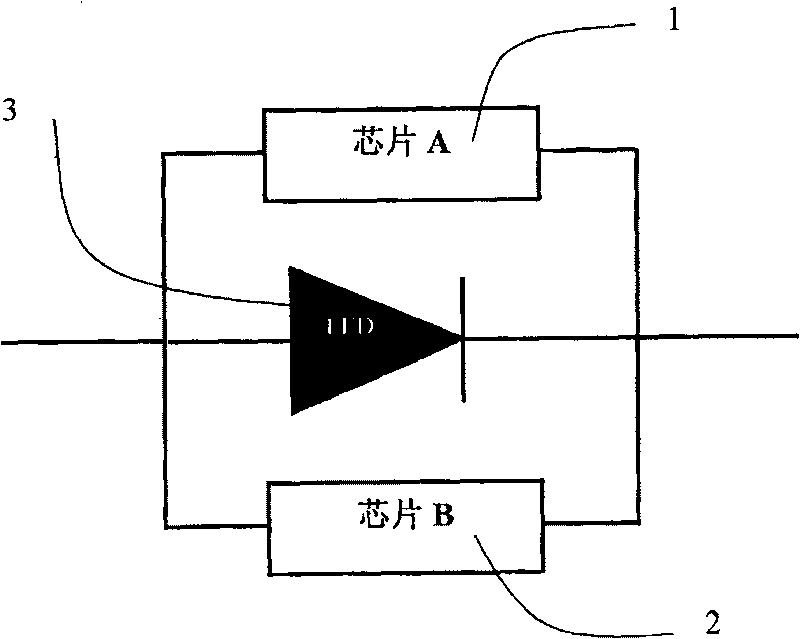

[0046] The circuit structure design of the multi-chip light-emitting diode module according to the present embodiment is as follows: figure 1 As shown, the module includes a voltage and current control integrated circuit chip 1, an antistatic integrated circuit chip 2 and a light-emitting diode chip 3. Among them, the chip 1 and the light-emitting diode LED chip 3 are connected in series, and can be adjusted according to the needs of the light-emitting diode LED chip. , Control the voltage on the LED chip and the passing current to realize different light-emitting modes of multi-chip and multi-color LED modules, such as flashing, color changing, gradually brightening, gradually dimming and other light-emitting modes. Chip 2 is an anti-static integrated A circuit chip, which is connected in parallel with the LED chip 3, to protect the LED chip from being damaged during high-voltage electrostatic discharge.

[0047] Although there is only one LED chip in this embodiment, those s...

Embodiment 2

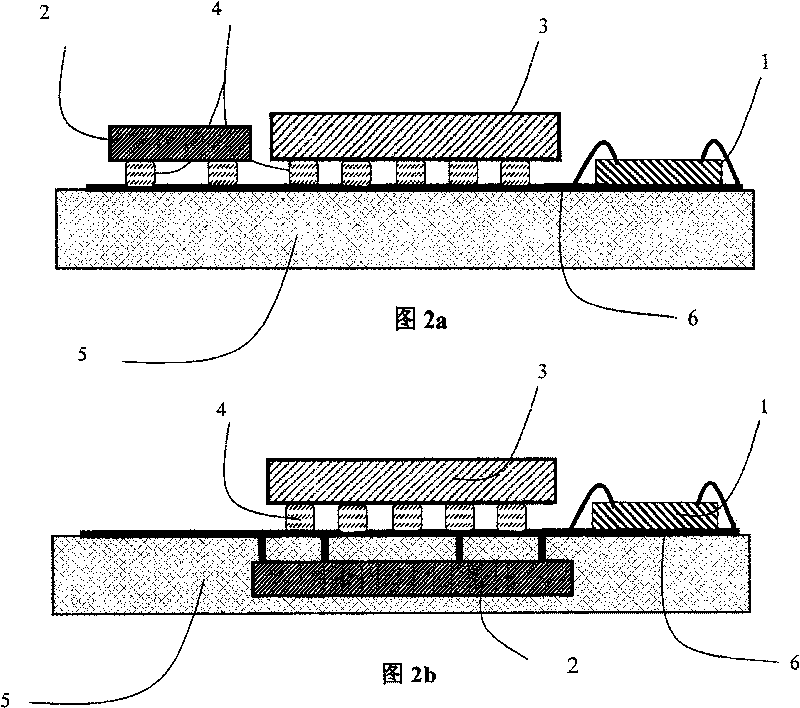

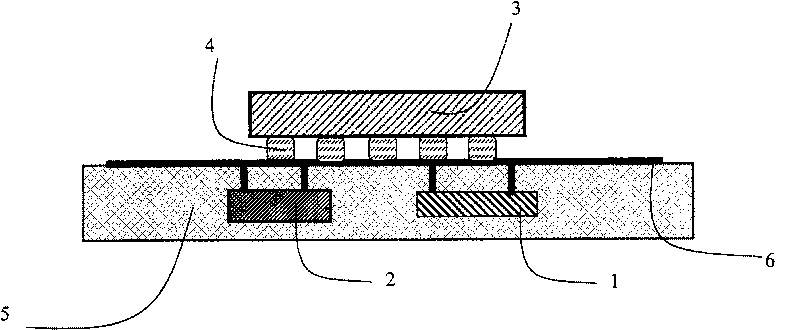

[0060] In this embodiment, aluminum nitride co-sintered ceramics (A1N) are used as the bottom plate material, and the integration of red, green and blue LED chips combined with the mounting of voltage and current control chips and antistatic chips is taken as an example and described with reference to the accompanying drawings.

[0061] Figure 7a It is a cross-sectional view of the AlN base plate 5, on which the corresponding metal circuits have been laid out according to the requirements of the red, green and blue LED chips 3a, 3b, 3c, current and voltage control chip 1 and anti-static chip 2, and the same LED chip and anti-static chip have been prepared. Chip 2 corresponds to metal bump 4 . Figure 7b It is a sectional view of a module integrating chip 1 and chip 2 and red, green and blue LED chips 3a, 3b, 3c. Figure 7c It is a top view of the multi-chip LED module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com