Glass fibre and magnesium wall and ceiling

A glass-magnesium wall and ceiling technology, applied in the field of building wall panel materials, can solve the problems of large use area, heavy brick wall, troublesome installation, etc., and achieve the effect of occupying a small building area, increasing the use area, and being convenient to install.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

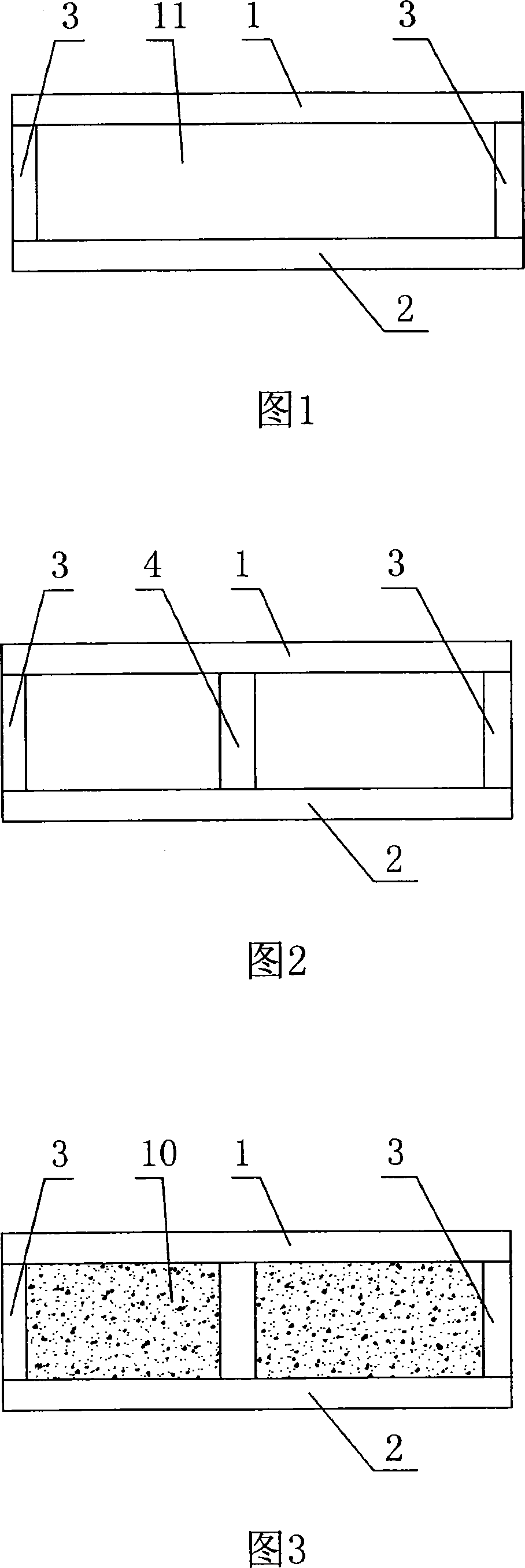

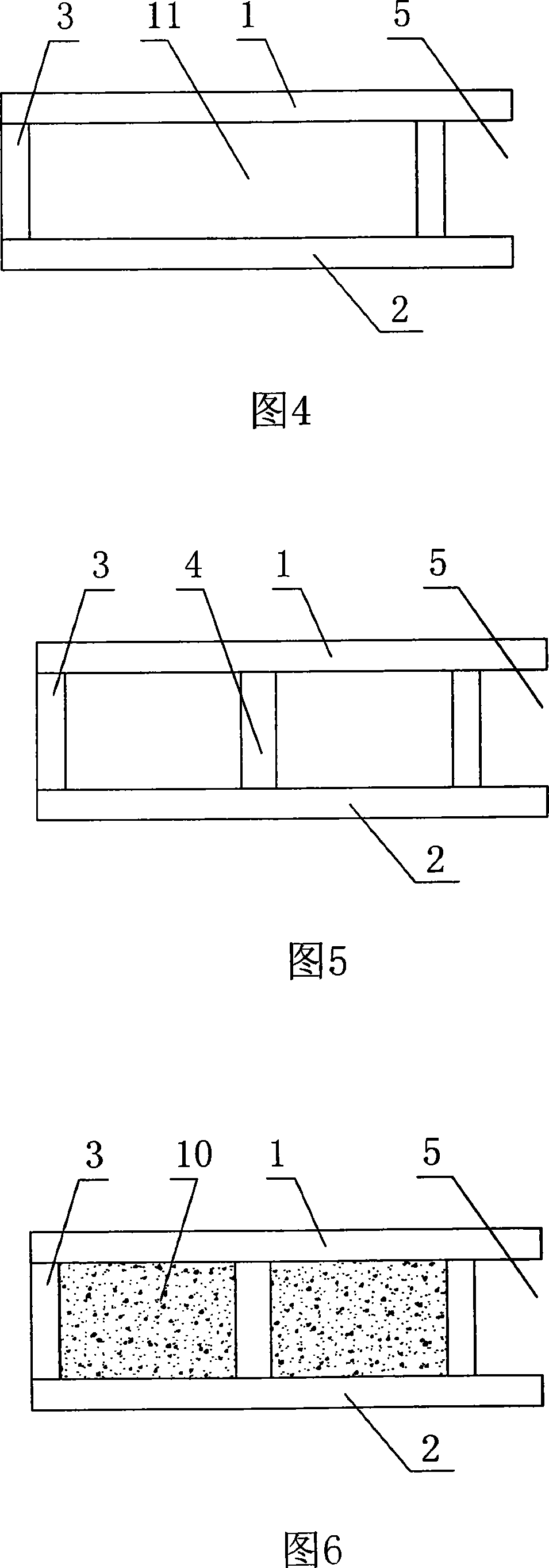

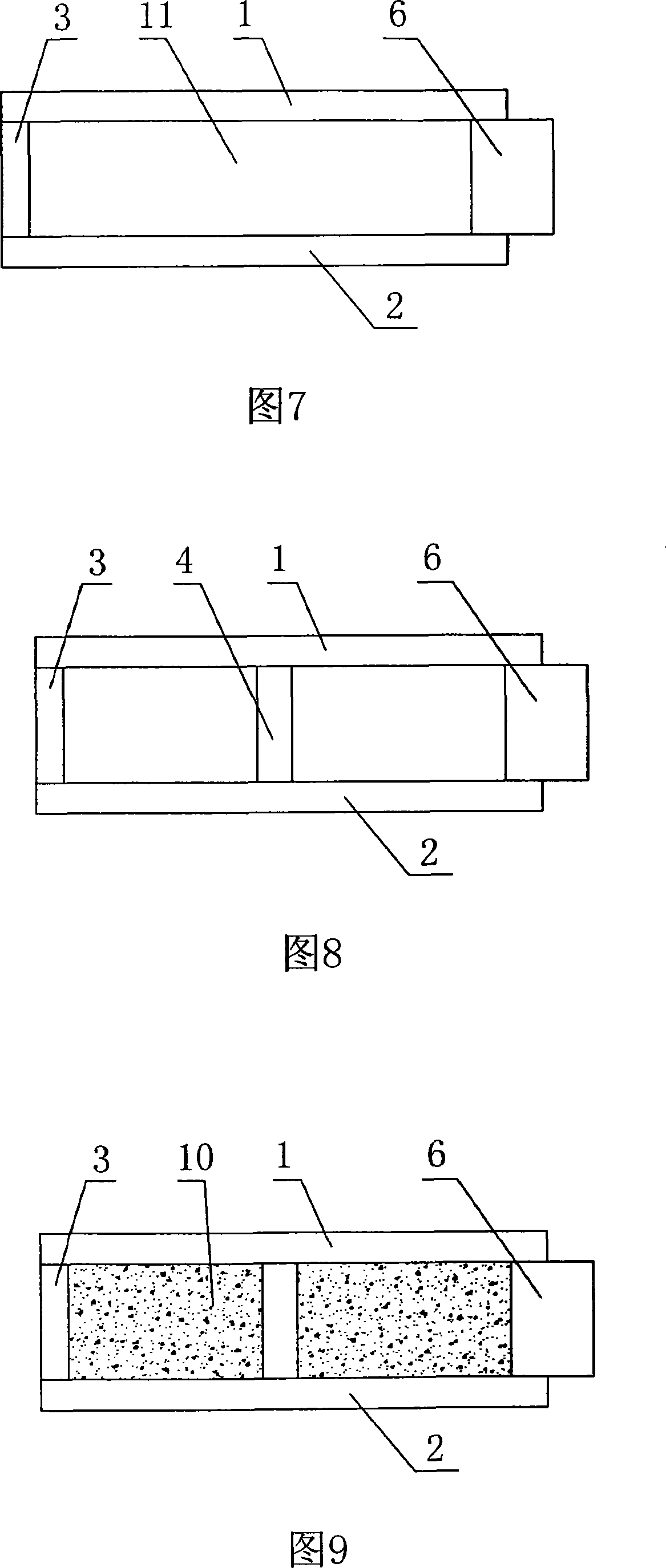

[0033] The Bomei board hollow wall is composed of a panel 1 , a bottom plate 2 and a side plate 3 . Both sides between the base plate 2 and the panel 1 are provided with side plates 3 and form a cavity 11 . The side plate 3 can be flush with both sides of the bottom plate 2 and the panel 1 ; or form a groove 5 with one side of the bottom plate 2 and the panel 1 ; or form a tenon 6 with one side of the bottom plate 2 and the panel 1 . The surface of the base plate 2 and the panel 1 can also paste metal sheets 7, one side of the two metal sheets 7 is made into a metal groove 8, and the other side is made into a metal tenon 9 matched with the metal groove 8. In the cavity 11, the large cavity 11 can be reduced by the partition plate 4, so as to facilitate processing and filling, and also increase the strength.

[0034] The cavity 11 can be filled with various fillers 10, such as: filling asbestos or double magnesium foam material or double magnesium plant fiber foam material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com