Method for cleaning cleaning polyalcohol lithium ion battery afflux liquid

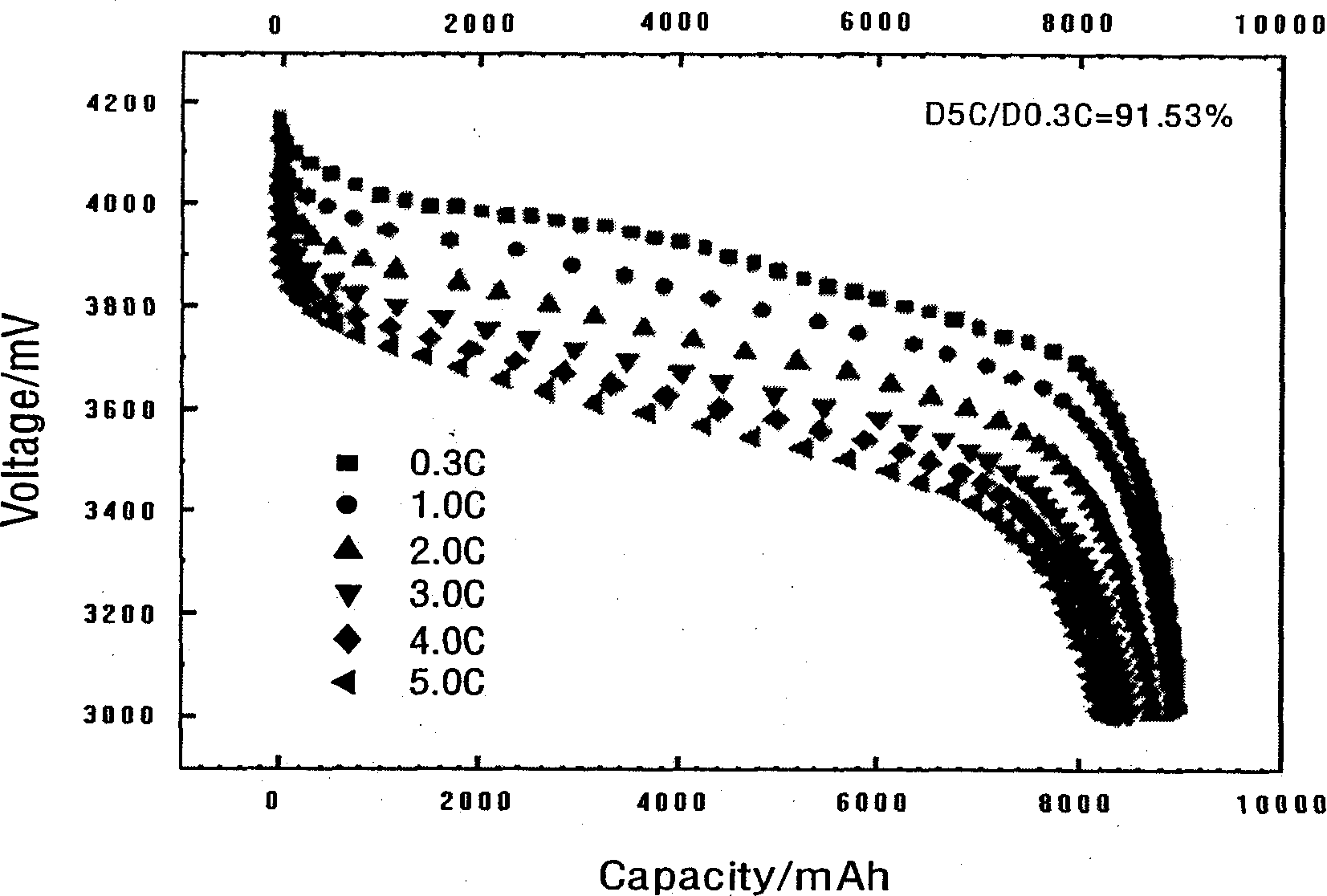

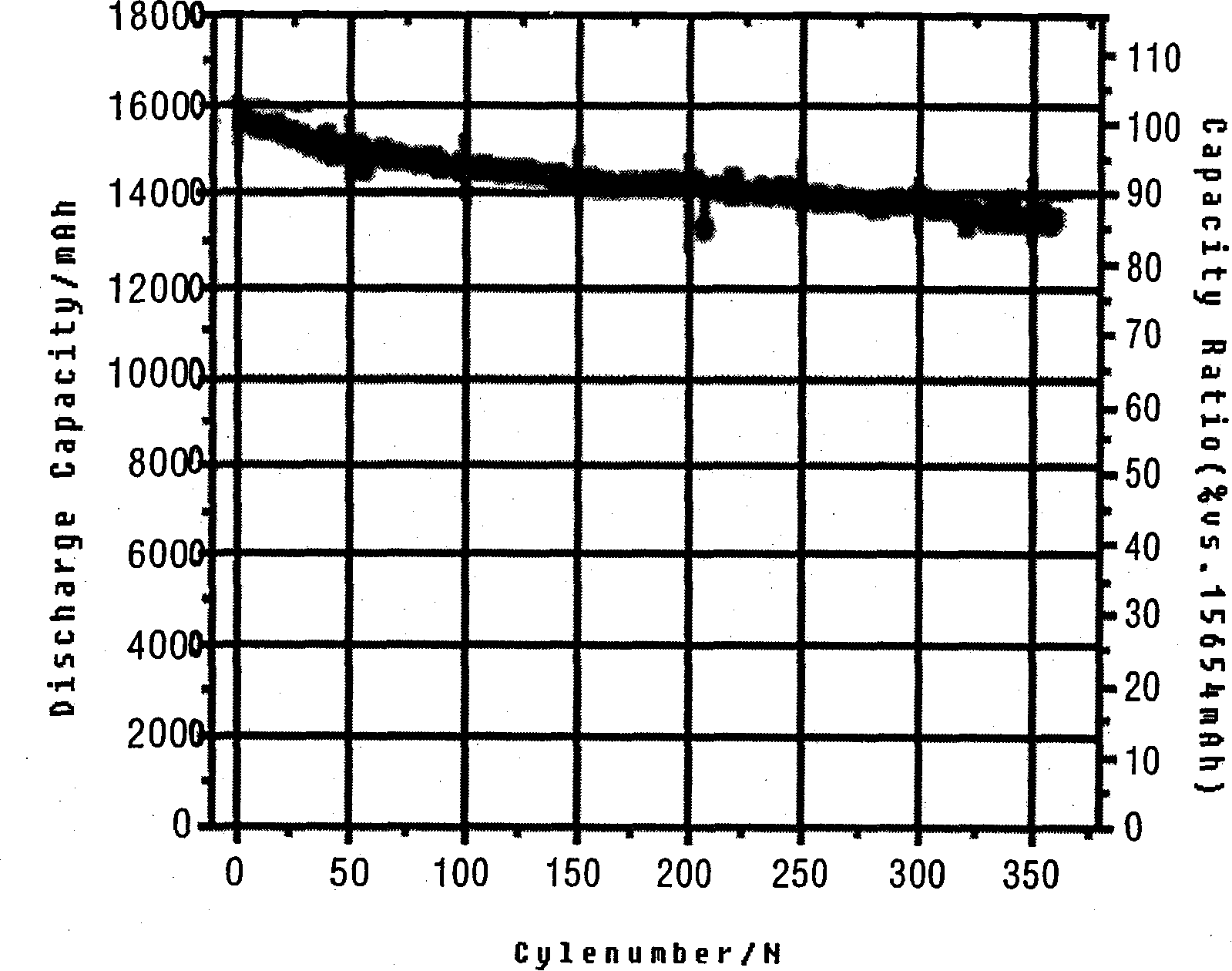

A technology for lithium-ion batteries and current collectors, applied in liquid cleaning methods, cleaning methods and utensils, inorganic non-surface-active cleaning compositions, etc., can solve the problem of poor cycle performance of rate discharge batteries, poor cleaning effect of current collectors, Low production efficiency and other issues, to achieve excellent battery cycle performance, improve battery consistency, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for cleaning a current collector, which uses a cleaning solution to ultrasonically clean a punched copper or aluminum mesh collector and then cleans the current collector with water; the cleaning solution contains the surface active sodium dodecylbenzene sulfonate The weight part is 80g of sodium carbonate detergent, 30g of sodium carbonate detergent, 10g of trihydric alcohol phosphate corrosion inhibitor and water, and then the current collector is continuously cleaned. Ultrasonic generating device, when the current collector flows through the liquid storage tank, the ultrasonic wave generates a powerful wave impact near the current collector and cooperates with the cleaning liquid to remove the dirt on the current collector. After ultrasonic cleaning, wash away the residual liquid on the current collector with clean water, then soak the copper current collector with a sulfuric acid solution with a pH value of 0.6 for 5 minutes, and soak the aluminum current co...

Embodiment 2

[0021] A method for cleaning a current collector, which uses a cleaning solution to ultrasonically clean a punched copper or aluminum mesh collector and then cleans the current collector with water; the cleaning solution contains the surface active sodium dodecylbenzene sulfonate The weight part is 80g of sodium carbonate detergent, 30g of sodium carbonate detergent, 10g of trihydric alcohol phosphate corrosion inhibitor and water, and then the current collector is continuously cleaned. Ultrasonic generating device, when the current collector flows through the liquid storage tank, the ultrasonic wave generates a powerful wave impact near the current collector and cooperates with the cleaning liquid to remove the dirt on the current collector. After ultrasonic cleaning, wash away the residual liquid on the current collector with clean water, soak the copper current collector with a sulfuric acid solution with a hydrogen ion concentration of 0.40mol / L for 10 minutes, and then soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com