Polysulfone/thermotropic liquid crystal polymer/rigid filled composite material and preparation method thereof

A technology of composite material and thermotropic liquid crystal, which is applied in the field of polysulfone/thermotropic liquid crystal polymer/rigid filler composite material and its preparation, can solve few problems, reduce viscosity, have broad application prospects, and improve processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

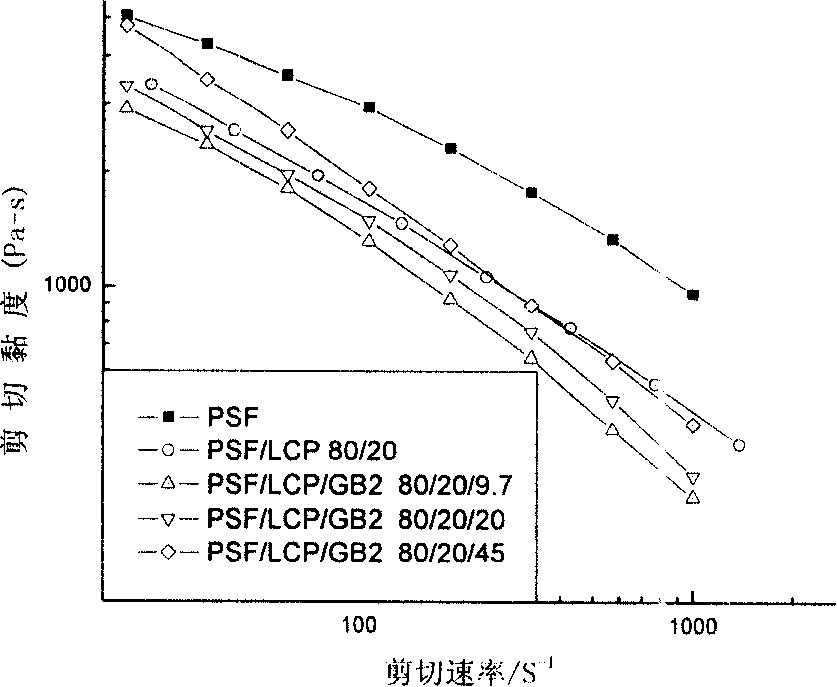

[0031] Fully dry polysulfone (intrinsic viscosity 0.54, 25°C, CHCl 3 ), thermotropic liquid crystal polymer (PHB / HNA73 / 27, Vectra A950, Ticona Celanese Company, USA) and hollow glass microspheres (GB2) with a diameter of 2 μm in weight ratio of 100 / 0 / 0, 80 / 20 / 0 , 80 / 20 / 9.7, 80 / 20 / 20.0 and 80 / 20 / 45.0 were melt blended on a Haake RC-90 internal mixer, the mixing temperature was 305°C, and the rotor speed was 50rpm. After granulation and drying, the obtained pellets were preheated at 290° C. for 6 minutes, and then the rheological properties were tested with a Rosand RH7 capillary rheometer. The inner diameter of the capillary used was 1 mm, and the aspect ratio was 16. The obtained viscosity data are all corrected by capillary end effect (Bagley correction), and the rheological curve of the obtained material is as follows: figure 1 shown.

Embodiment 2

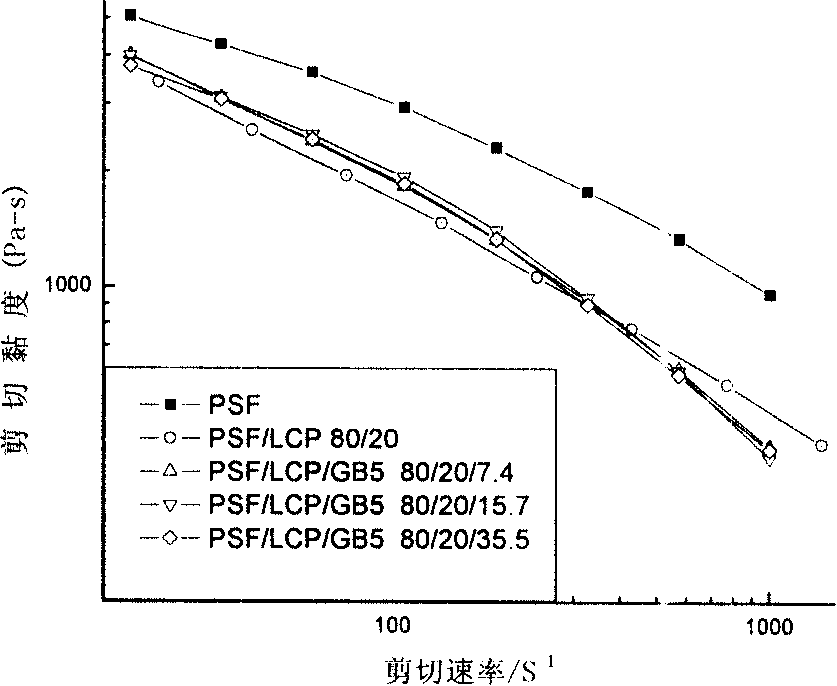

[0036] Fully dry polysulfone (intrinsic viscosity 0.54, 25°C, CHCl 3 ), thermotropic liquid crystal polymer (PHB / HNA73 / 27, Vectra A950, Ticona Celanese Company, USA) and hollow glass microspheres (GB5) with a diameter of 5 μm in a weight ratio of 100 / 0 / 0, 80 / 20 / 0, 80 / 20 / 7.4, 80 / 20 / 15.7 and 80 / 20 / 35.5 were melt blended on a Haake RC-90 internal mixer. Blending condition and rheological property test condition are the same as embodiment 1, and the rheological curve of gained material is as follows image 3 shown.

Embodiment 3

[0041] Fully dry polysulfone (intrinsic viscosity 0.54, 25°C, CHCl 3 ), thermotropic liquid crystal polymer (PHB / HNA73 / 27, Vectra A950, Ticona Celanese Company, USA) and hollow glass microspheres (GB20) with a diameter of 20 μm in a weight ratio of 100 / 0 / 0, 80 / 20 / 0, 80 / 20 / 6.5, 80 / 20 / 14.0 and 80 / 20 / 31.3 were melt blended on a Haake RC-90 internal mixer. Blending conditions and rheological performance test conditions are the same as in Example 1. The rheological curve of the obtained material is as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com