Functional uv paint, construction material using the same, and method of preparing the paint

A coating and raw material technology, applied to building materials using the coating and preparing the coating, relates to the field of functional UV coatings, which can solve the problems of VOC and HCHO without taking into account, and achieve the effect of reducing VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

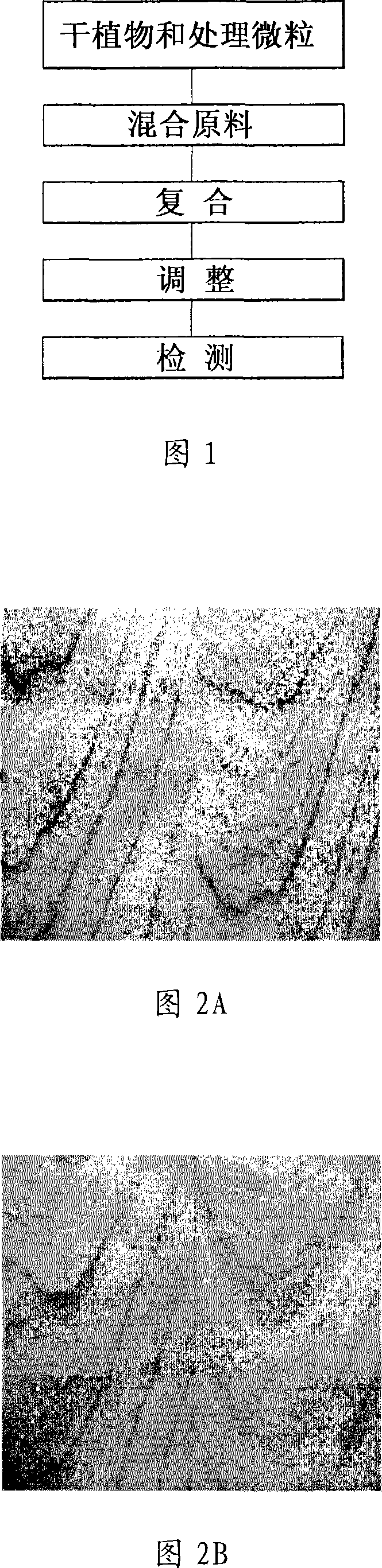

Method used

Image

Examples

Embodiment 1

[0089] Use a grinder to grind the green tea leaves at high speed. Only fine particles having a particle size of 0.02 to 125□ were screened out of the fine particles sorted by the blower. After the paint raw materials were well mixed, green tea powder was added to the paint raw materials having the contents shown in Table 4 and dispersed to obtain UV paint. In Table 4, urethane acrylate and epoxy acrylate were used as oligomers (60 wt %), and styrene monomers or acrylate monomers including dipentaerythrytol hexaacrylate were used as monomers (25wt%), and photoinitiator (4wt%), additive (1wt%) and extender (8wt%) with two or more functional moieties were used. The paint raw material is AULEX893FK-HV and No. 050404 green tea (2wt%) is added.

[0090] Table 4

[0091] components

Embodiment 2

[0093] A UV paint was prepared in the same manner as in Example 1, except that 7 wt % of an extender pigment and 2.5 wt % of green tea powder were used.

Embodiment 3

[0095] A UV paint was prepared in the same manner as in Example 1 except that 7 wt % of the extender pigment and 3 wt % of green tea powder were used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com