Optical sensor, solid-state imaging device, and operation method of solid-state imaging device

A technology of solid-state imaging device and light sensor, which is applied in electric solid-state devices, radiation control devices, image communication, etc., can solve the problems of low S/N ratio, low sensitivity, damage to the quality of animation camera images, etc., and achieve high S/N ratio, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

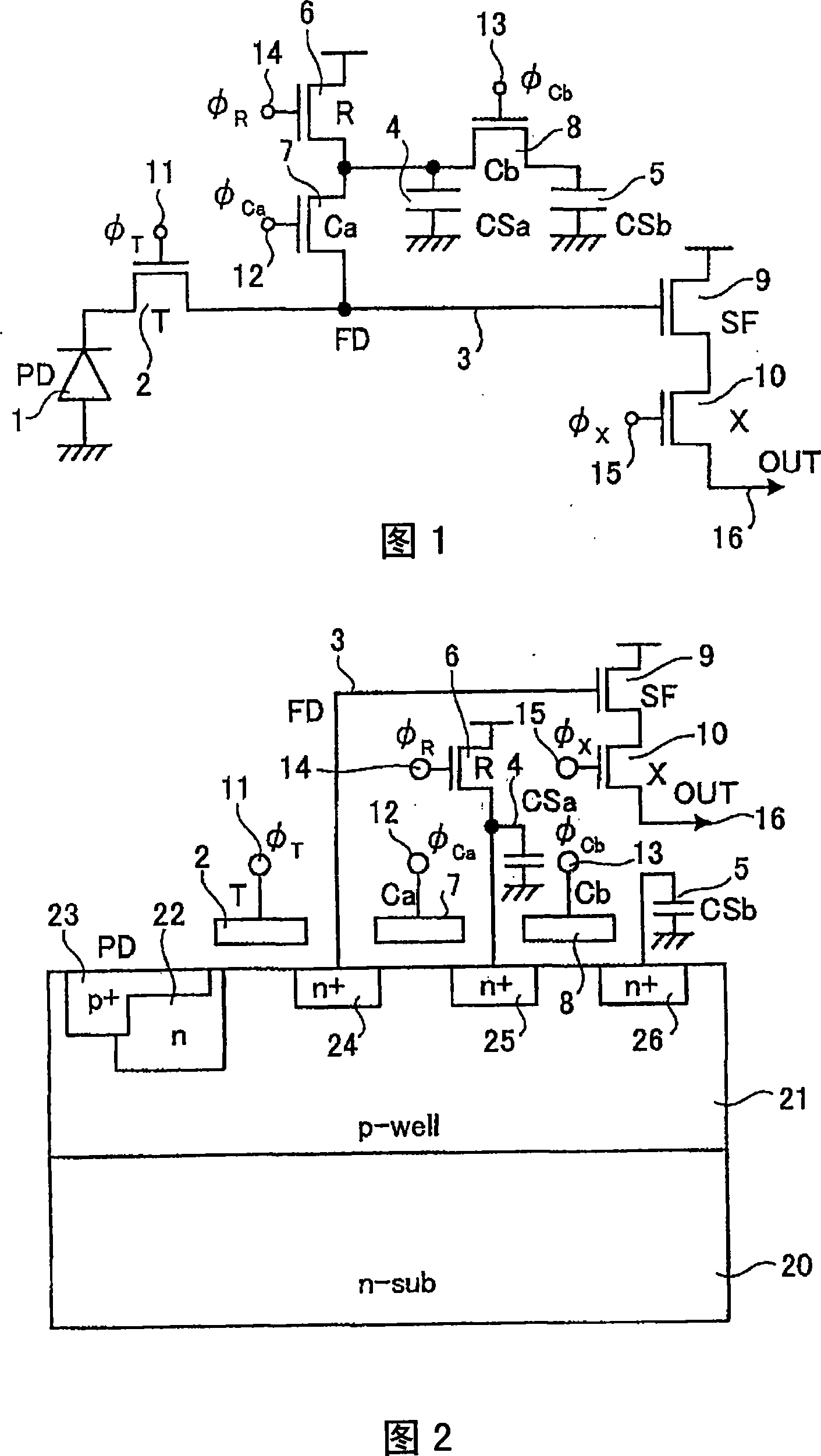

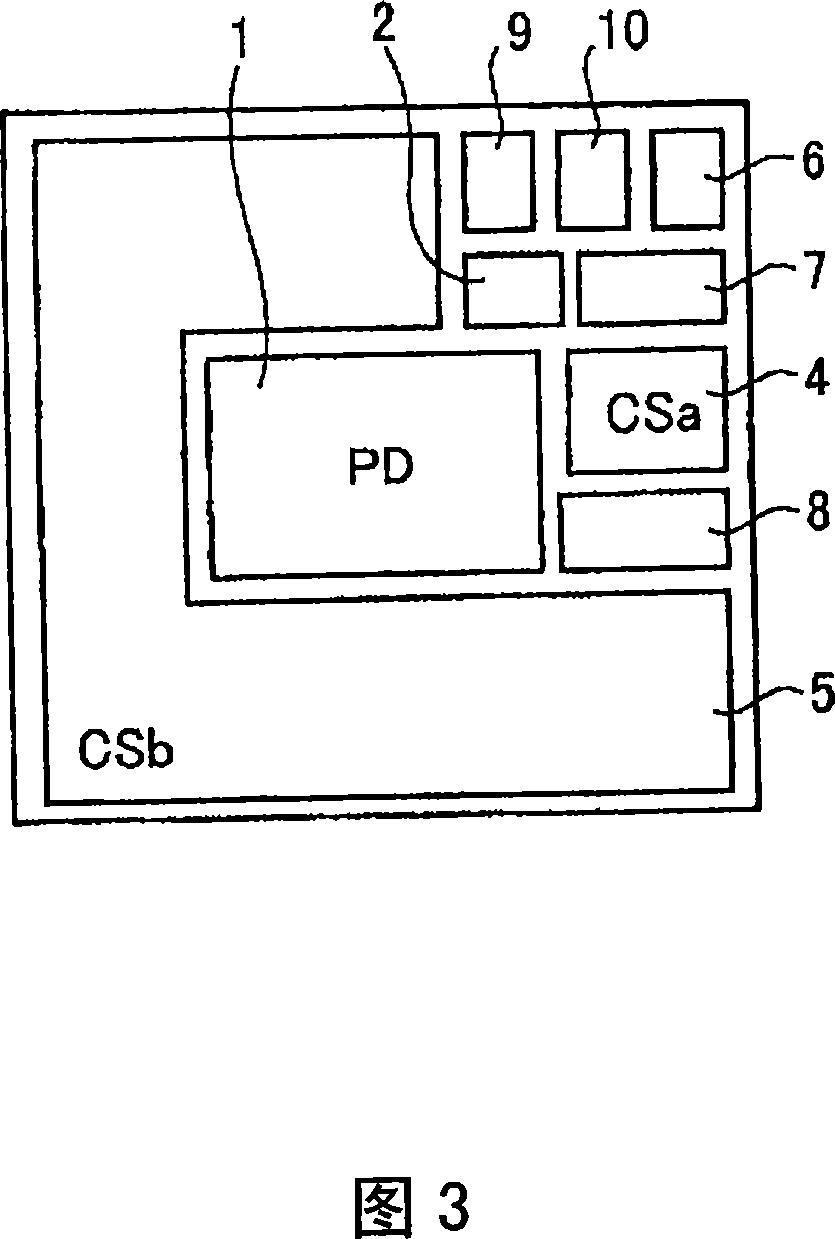

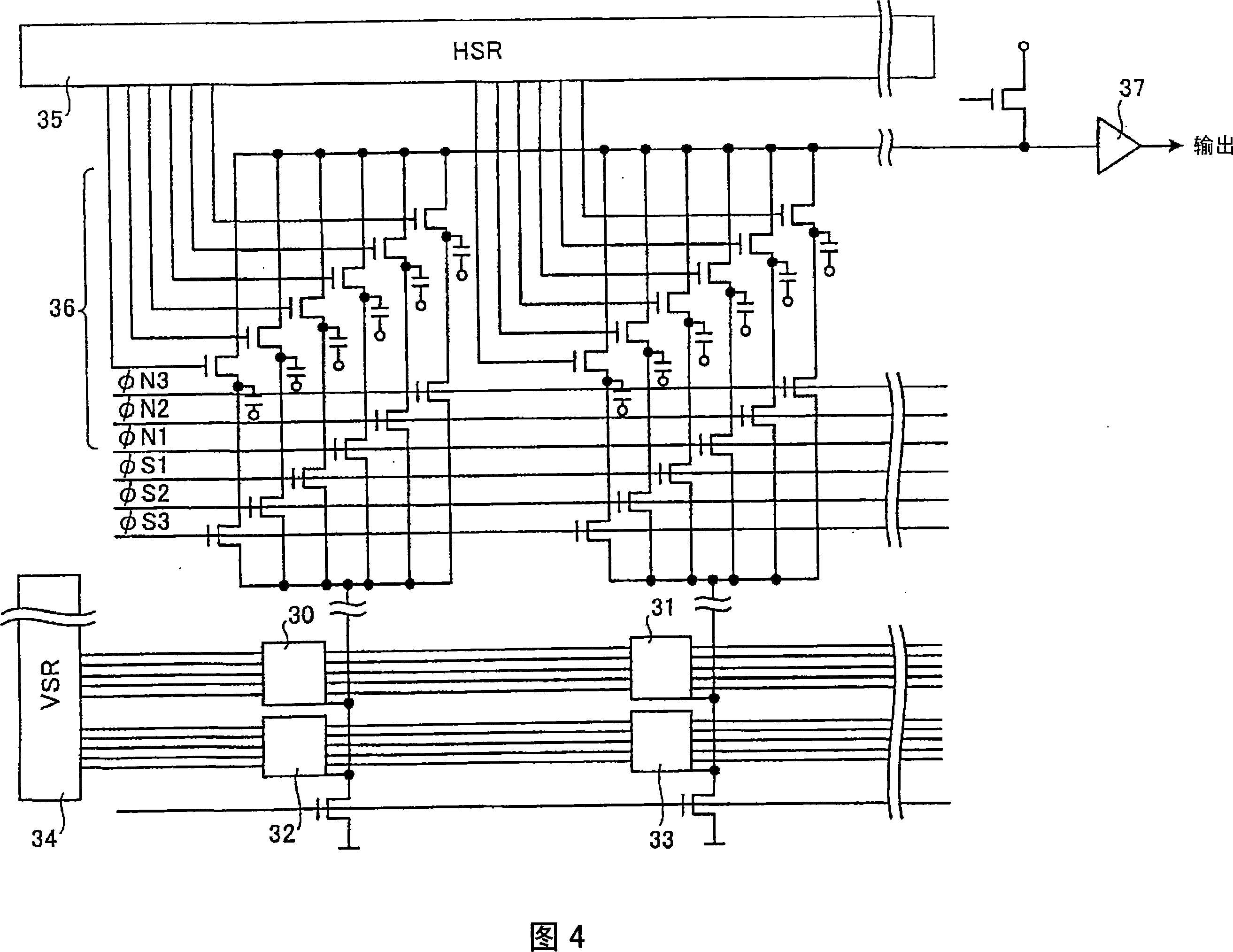

[0079] FIG. 1 shows an equivalent circuit diagram of one pixel of the solid-state imaging device according to this embodiment, FIG. 2 shows a schematic cross-sectional view, and FIG. 3 shows a schematic plan view.

[0080]Each pixel is composed of the following parts: a photodiode PD1 that receives light and generates photocharges; a transfer transistor T2 that transmits photocharges provided adjacent to the photodiode PD1; a floating diffusion FD3 that is connected to the photodiode PD1 via the transfer transistor T2; The transfer transistor T2 stores the first storage capacitor CSa4 and the second storage capacitor CSb5 of the photocharge overflowed from the photodiode PD1 during the exposure and storage operation; it is connected to the first storage capacitor CSa4 to discharge the first storage capacitor. Capacitor CSa4, second storage capacitor CSb5 and reset transistor R6 for signal charge in floating diffusion FD3; first storage transistor Ca7 arranged between floating d...

no. 2 approach

[0108] This embodiment is an embodiment of another operating method of the solid-state imaging device according to the first embodiment. The configuration of the solid-state imaging device of this embodiment is the same as that of the solid-state imaging device of the first embodiment described with reference to FIGS. 1 to 4 . However, the threshold voltage of the first storage transistor Ca and the second storage transistor Cb is lower than that of the transfer transistor T. As shown in FIG.

[0109] 8 is a main driving time chart of the solid-state imaging device according to this embodiment, and FIG. 9 is a partial schematic potential diagram from a photodiode of a pixel through a floating diffusion FD, a first storage capacitor, and a second storage capacitor.

[0110] First, before exposure and storage, the first storage transistor Ca and the second storage transistor Cb are turned on, and the transfer transistor T and reset transistor R are turned off. Next, the reset t...

no. 3 approach

[0117] FIG. 10 shows an equivalent current diagram of one pixel of the solid-state imaging device of this embodiment, and FIG. 11 shows a schematic cross-sectional view, and the schematic plan view is the same as that of FIG. 3 of the first embodiment.

[0118]Each pixel is composed of the following parts: a photodiode PD1 that receives light and generates photocharges; a transfer transistor T2 that transmits photocharges provided adjacent to the photodiode PD1; a floating diffusion FD3 that is connected to the photodiode PD1 via the transfer transistor T2; During the exposure storage operation, the first storage capacitor CSa4 and the second storage capacitor CSb5 that store the photocharge overflowed from the photodiode PD1 through the transfer transistor T2 are connected to the floating diffusion FD3 to discharge the floating diffusion FD3 and the first storage capacitor. Capacitor CSa4 and the reset transistor R6 of the signal charge in the second storage capacitor CSb5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com