Control method for biological flocculant XM-11 fermentation process grading oxygen supply

A technology of XM-11 and biological flocculants, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as analysis and in-depth systematic research, so as to reduce production energy consumption, reduce production costs, The effect of promoting the process of practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

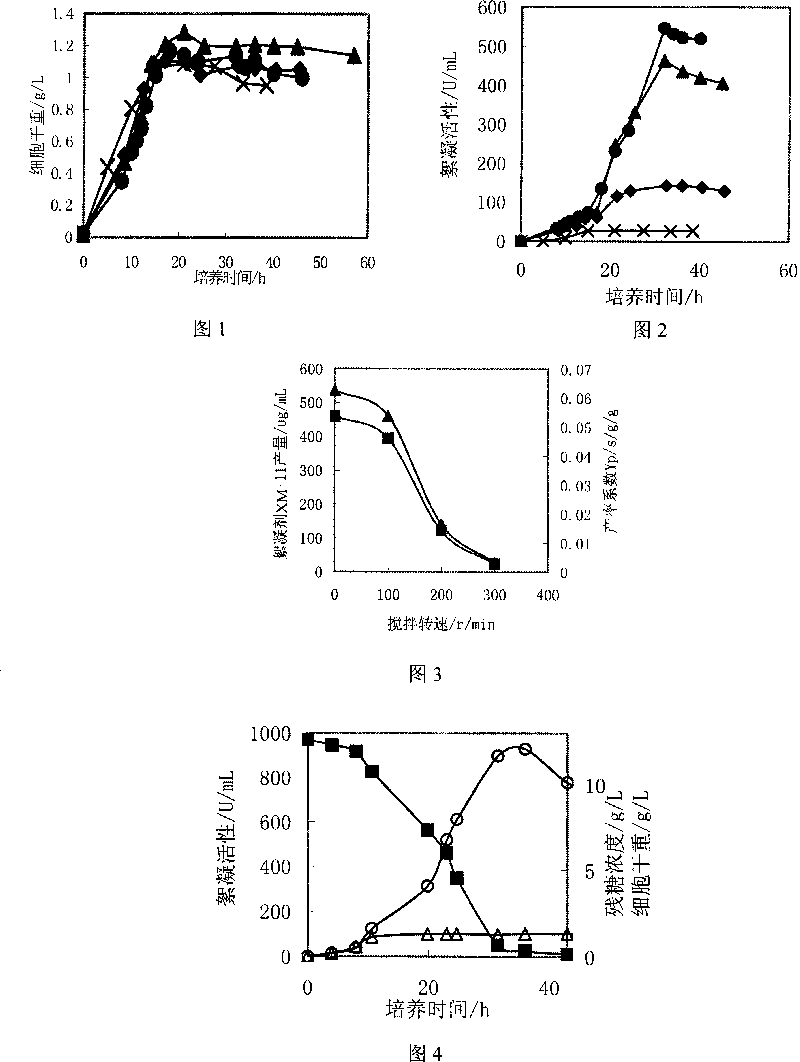

[0027] The liquid fermentation medium used included glucose 15g / L, urea 0.5g / L, and yeast extract 0.5g / L; the seed culture time was 8 hours, the inoculum size was 8%; the fermentation temperature was 25°C, and the initial pH of the medium was 4.0. A single stirring speed was maintained during the fermentation process, and the effects of different stirring speeds on the growth of bacteria were investigated. Figure 1 is the curve of the change of the bacterial volume of the bioflocculant synthetic strain with time at different stirring speeds.

[0028] As can be seen from Figure 1, there is an optimum stirring speed for the growth of bacteria——100r / min. If the stirring speed is too high or too low, the growth of the bacteria will decrease; but at a higher stirring speed, the specific growth rate of the bacteria Higher, which can shorten the time for the bacteria to reach the maximum growth. For example, when fermentation is carried out at 300r / min, the time for bacterial growth...

Embodiment 2

[0030] Using the fermentation conditions as described in Example 1, the influence of stirring speed on the growth of bacteria was investigated. The difference is that the liquid fermentation medium used contains 20g / L glucose, 1g / L urea, and 1g / L yeast extract; the seed culture time is 16 hours, the inoculum size is 15%; the fermentation temperature is 30°C, and the initial pH of the medium is 10.0.

Embodiment 3

[0032] Using the fermentation conditions as described in Example 1, the influence of stirring speed on the growth of bacteria was investigated. The difference is that in the liquid fermentation medium used, the glucose is 18g / L, the urea is 0.8g / L, and the yeast extract is 0.8g / L; the seed culture time is 12h, and the inoculum size is 10%; the fermentation temperature is 28°C, and the initial pH of the medium is 7. 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com