Method for preparing caprolactam

A technology of caprolactam and cyclohexyl formic acid, applied in the field of preparation of caprolactam, can solve problems such as insufficient economy and environmental friendliness, and achieve the effects of convenient acquisition, high conversion rate and selectivity, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

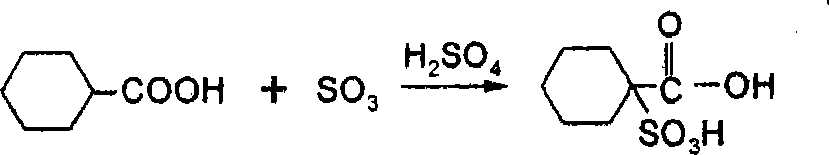

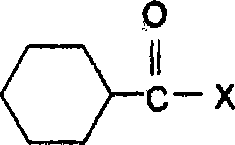

Method used

Image

Examples

Embodiment 2~7

[0044] Examples 2-7: Raw material ratio, feeding method and reaction time are the same as in Example 1, the difference is that after the mixed acid anhydride is obtained by the pre-mixing reaction, the rearrangement liquid is added first and then the nitrosation reaction is carried out, and the amount of the rearrangement liquid is converted into caprolactam respectively 1.00g, 2.04g, 3.01g, 4.05g, 5.04g and 7.02g, corresponding to 9.73%, 19.84%, 29.27%, 39.39%, 49.02% and 68.27% of the yield of caprolactam in Example 1.

[0045] See Table 1 for the nitrosation conversion rate, yield and selected row results of adding caprolactam in advance.

[0046]

Embodiment 9

[0048] Example 9: Raw material ratio, feeding method and reaction time are the same as those of Comparative Example 8, the difference is that 1.88 g of rearrangement liquid with a caprolactam concentration of 39.86% is added first, and then nitrosation reaction is carried out, and the amount of rearrangement liquid converted into caprolactam is 0.75 g, corresponding to 20.96% of the yield of caprolactam in Example 8. Analysis and calculation showed that the conversion rate of nitrosation reaction was 38.27%, the yield of caprolactam was 37.03%, and the selectivity of caprolactam was 93.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com