Technique for producing resin

A production process and resin technology, which is applied in the field of new resin production process, can solve the problems of undiscovered resin, etc., and achieve the effect of easy-to-obtain raw materials, low cost and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

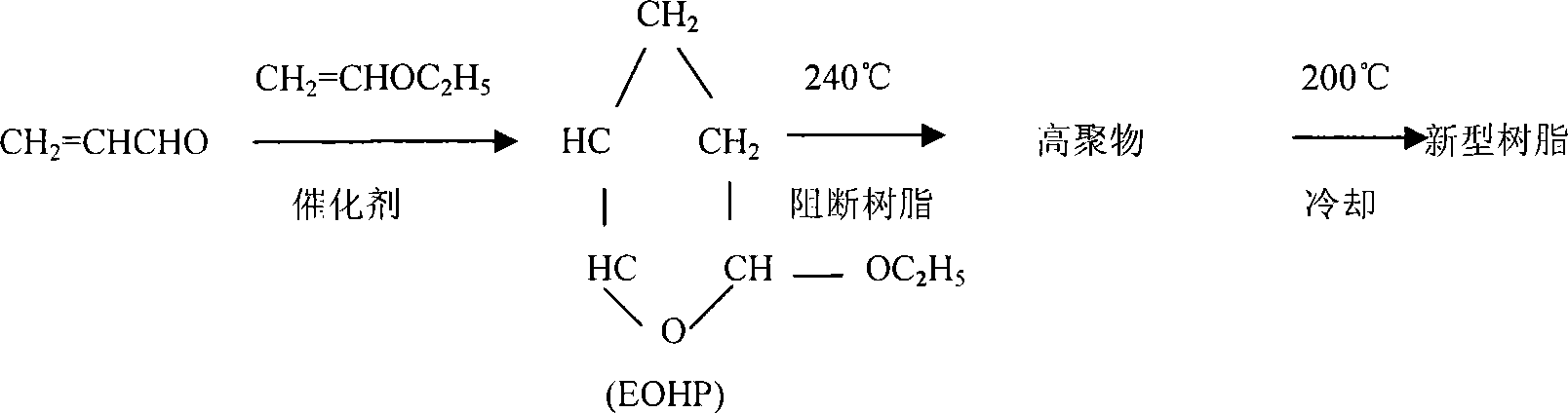

[0037] Example 1. A production process of a new type of resin, which is prepared through the condensation reaction of acrolein and vinyl ether.

Embodiment 2

[0038] Example 2. A production process of a new type of resin, which is prepared through the condensation reaction of acrolein and vinyl ether, and the production steps of the condensation reaction are as follows:

[0039](1) Put vinyl ethyl ether into the condensation kettle, then put the catalyst zinc salt or aluminum salt into the kettle, start stirring, then put acrolein into the condensation kettle, close the valve after feeding, and at the same time, heat the jacket of the condensation kettle with hot water, Slowly raise the temperature, and cool the condenser above the condensation kettle to reflux the solution. When the temperature in the condensation kettle rises to 60°C, stop heating, cool to below 30°C, and pump the material into the distillation pot;

[0040] (2) Distill the obtained material to 230°C under atmospheric pressure, open the valve of the storage tank above the still, and put blocking resin into the still, after co-melting, collect all fractions below 2...

Embodiment 3

[0041] Example 3. A production process of a new type of resin, which is prepared through the condensation reaction of acrolein and vinyl ether, and the production steps of the condensation reaction are as follows:

[0042] (1) Put vinyl ethyl ether into the condensation kettle, then put the catalyst zinc salt or aluminum salt into the kettle, start stirring, then put acrolein into the condensation kettle, close the valve after feeding, and at the same time, heat the jacket of the condensation kettle with hot water, Slowly raise the temperature, and cool the condenser above the condensation kettle to reflux the solution. When the temperature in the condensation kettle rises to 65°C, stop heating, and after cooling to 25°C, pump the material into the distillation pot;

[0043] (2) Distill the obtained material to 240°C at atmospheric pressure, open the valve of the storage tank above the still, and put blocking resin into the still, after co-melting, collect all fractions below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com