A converter for energy conversion of superconductive energy storage system

A superconducting energy storage and energy conversion technology, applied in the field of converters, can solve the problems of restricting the application of superconducting energy storage systems, unfavorable superconducting magnet system stability, increasing magnet AC loss, etc., achieving compact structure and reducing construction costs. Cost, effect of simplifying structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

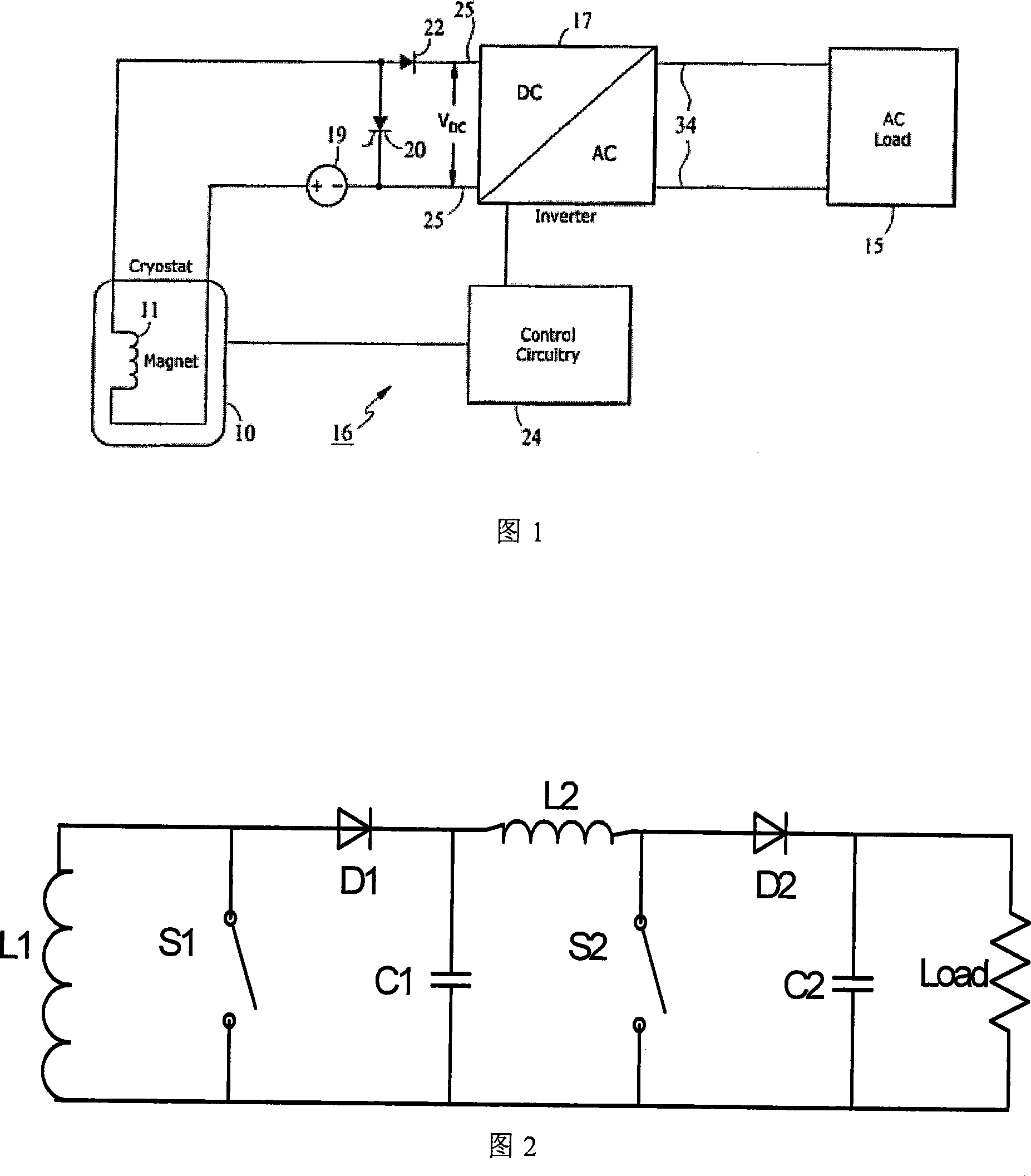

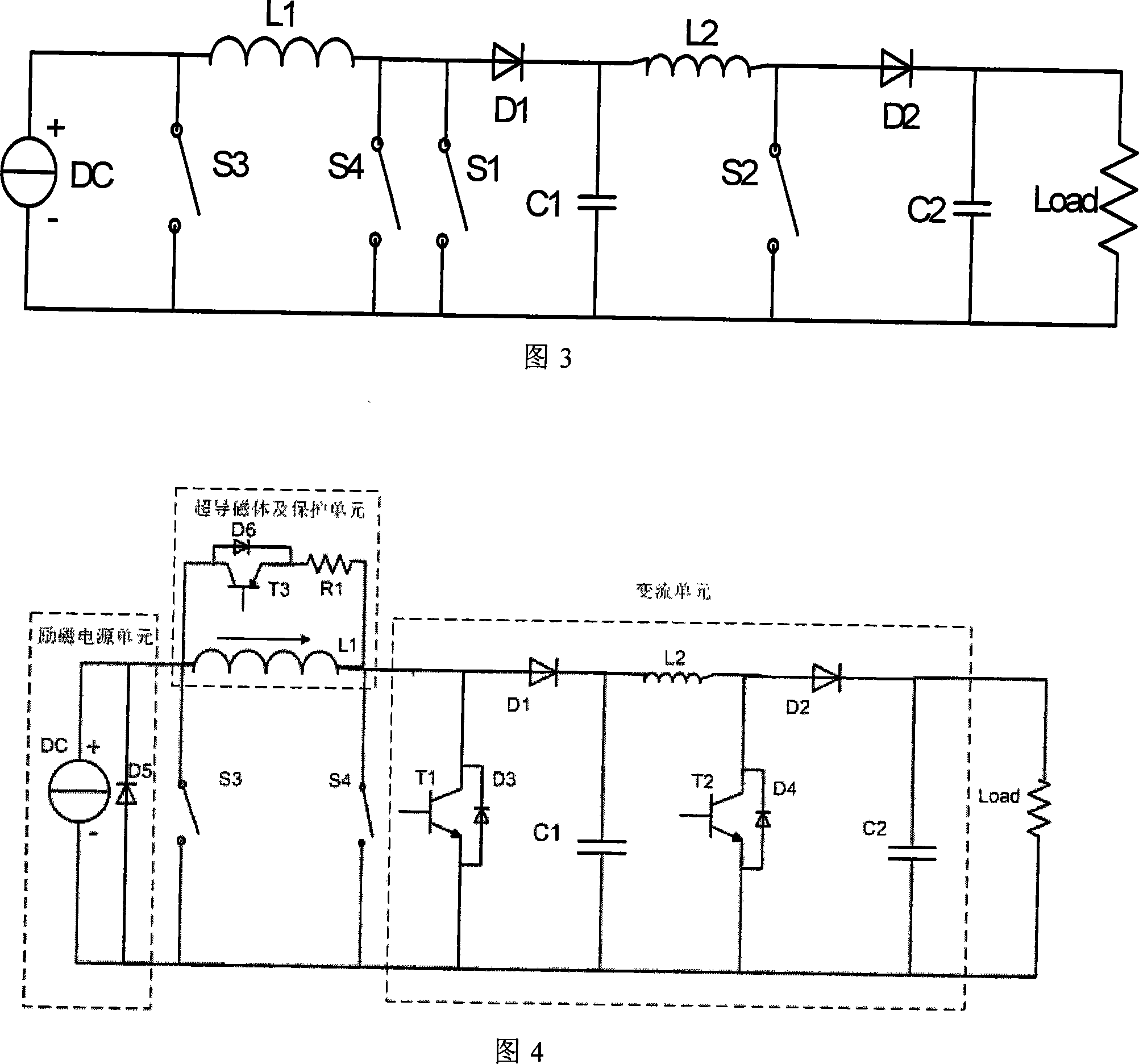

[0014] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0015] FIG. 2 is a schematic diagram of the main circuit of the present invention. As shown in Figure 2, L1 is a superconducting magnet, L2 is a continuous energy inductor, S1 is a first-stage chopper switch, D1 is a first-stage chopper diode, and C1 is a first-stage chopper capacitor. The anode of the diode D1 is connected in parallel with the superconducting magnet L1 and one end of the first-stage chopper switch S1 respectively, and the cathode of the diode D1 is connected in parallel with the first-stage chopper capacitor C1 and one end of the continuous energy inductor L2 respectively. The other end of the first-stage chopper capacitor C1 is connected in parallel with the superconducting magnet L1 and the other end of the first-stage chopper switch S1 respectively. When the switch S1 is closed, the current in the superconducting magnet L1 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com