Environment-protection energy-saving lubricant oil for removing carbon deposition effectively

An environmental protection, energy saving, lubricating oil technology, applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problems of uneconomical use, durability, high manufacturing cost, and slow effect in the use process, so as to prolong the service life and save fuel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

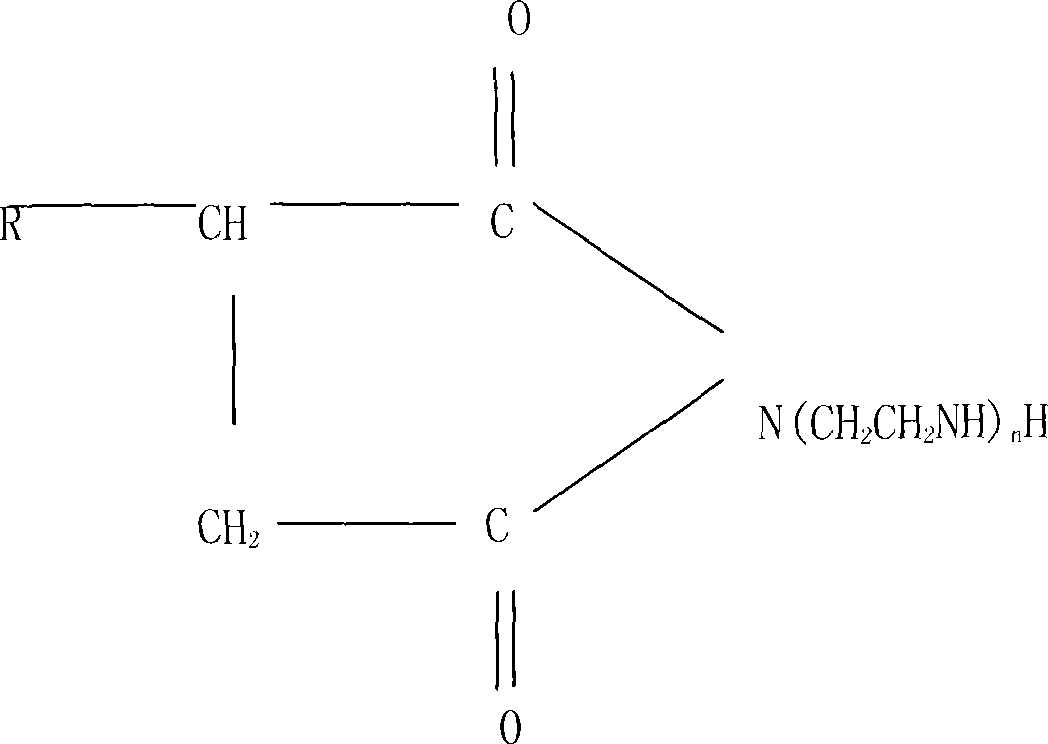

[0039] Preparation of carbon remover (the same below):

[0040] Prepare the mixed salt solution of Mg and Al according to a certain ratio, Mg 2+ 、Al 3+ The total concentration of ions is 1.5mol / L, Mg 2+ and Al 3+ The molar ratio is 1.5~4:1.

[0041] Mixed alkali solution of sodium carbonate and sodium hydroxide prepared at room temperature, (CO 3 2- ): (OH - ) in a molar ratio of 1:2.

[0042] The mixed salt solution and the mixed alkali solution were dropped into containers containing deionized water at a temperature of 65°C, while vigorously stirring to keep the pH value at 10. After the drops were completed, the resulting slurry was aged at 65°C for half an hour, and then Suction filtration, beating and washing the filter cake for half an hour, and then suction filtration, repeated several times, and finally put the filter cake in an oven to evaporate overnight at 120 ° C, and put the evaporated filter cake in a muffle furnace at 600 It is calcined at a temperature ...

Embodiment 2

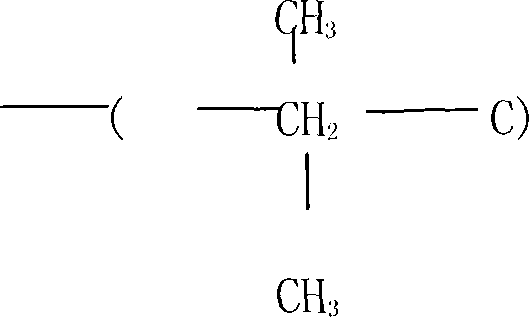

[0048] First, pump 74KG of mineral-type liquid lubricating oil after dehydration pretreatment into the homogeneous kettle at one time, then add 5KG of succinimide dispersant into the kettle after metering, then start stirring and heat up to 60°C , and then 8KG of molybdenum disulfide powder with a particle size of 60 microns, 5KG of Al with a particle size of 60 microns 2 o 3 , 3KG MgO with a particle size of 60 microns, 2KG decarburizer, add to the kettle several times, start to shear and disperse after adding, and control the temperature between 60°C and 70°C. At this time, circulating cooling can be used Adjust the temperature with water, and after two hours, add 3KG of anti-wear agent molybdenum dialkyldithiophosphate into the kettle after metering, continue shearing and dispersing for two hours, then take a sample to test the particle size distribution, and stop shearing if it is qualified. Cut and disperse, then circulate the sand mill for four hours, continue to contro...

Embodiment 3

[0050] First, pump 72KG of mineral-type liquid lubricating oil after dehydration pretreatment into the homogeneous kettle at one time, then add 4KG of succinimide dispersant into the kettle after metering, then start stirring and heat up to 60°C , and then 7KG of molybdenum disulfide powder with a particle size of 50 microns and 7KG of Al with a particle size of 50 microns 2 o 3 , 4KG MgO with a particle size of 50 microns, 2KG carbon remover, add to the kettle several times, start shear dispersion after adding, and control the temperature between 60°C and 70°C, at this time, circulation cooling can be used Adjust the temperature with water, and after two hours, add 4KG of anti-wear agent molybdenum dialkyl dithiophosphate into the kettle after metering, continue to shear and disperse for two hours, then take a sample to test the particle size distribution, and stop shearing if it is qualified. Cut and disperse, then circulate the sand mill for four hours, continue to control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com