Novel pseudo-classic brick and method for manufacturing same

A manufacturing method and technology of antique bricks, applied in the field of building decoration materials and their manufacturing, can solve the problems of small color selection range, poor acid (alkali) resistance, unsatisfactory gloss, etc., and achieve easy product conversion, good product performance, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

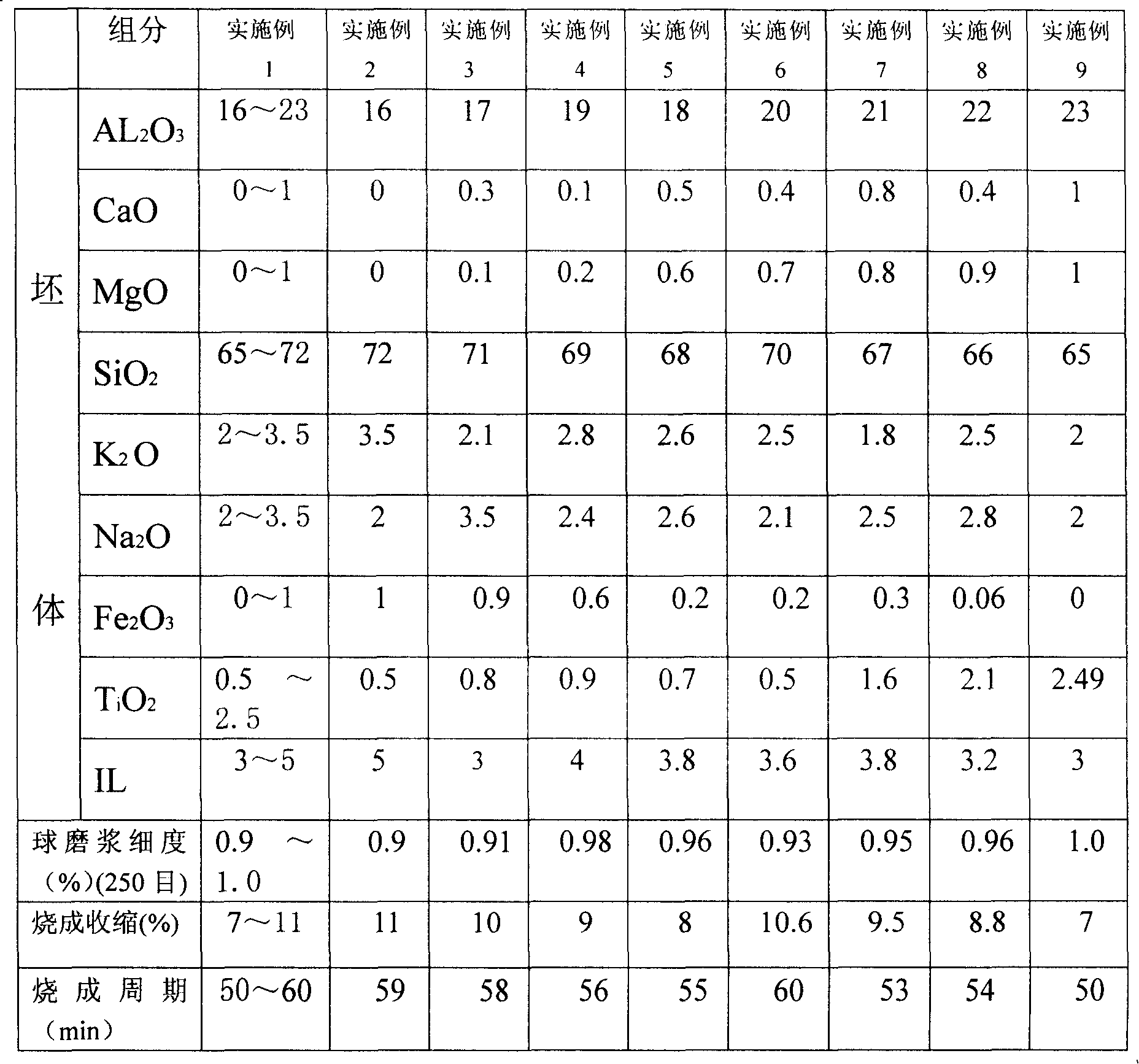

[0025] The present invention will be further described in detail below in conjunction with specific examples (each component of the blank is in weight percentage):

[0026]

[0027] Continued

[0028] Firing temperature

Degree (℃)

1200~

1210

1200

1209

1208

1206

1207

1205

1203

1210

Ball mill mud

Pulp specific gravity

(g / cm 3 )

1.7~

1.72

1.7

1.72

1.71

1.716

1.718

1.714

1.71

1.705

Ball mill mud

Slurry flow rate

(S)

16~23

16

17

18

19

20

21

22

23

Powder water

Servings (%)

5.8~

6.2

5.8

5.85

5.9

5.86

5.95

6

6.1

6.2

[0029] The process flow of the manufacturing method is as follows: raw materials enter the factory→inspection→proportioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com