Preparation method of health preserving jute blended yarn

A technology of blending yarn and jute, applied in yarn, textile and paper making, liquid/gas/vapor removal by centrifugal force, etc., can solve the problem of thick jute fiber, difficulty in forming cotton web, and low fineness of high-proportion jute blended yarn And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

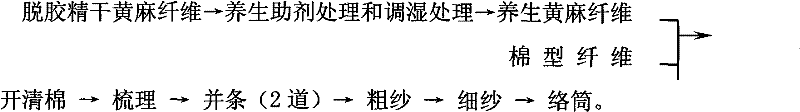

Method used

Image

Examples

Embodiment 1

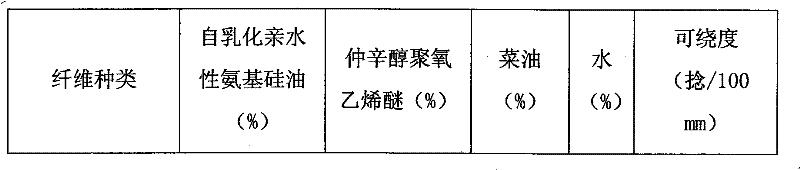

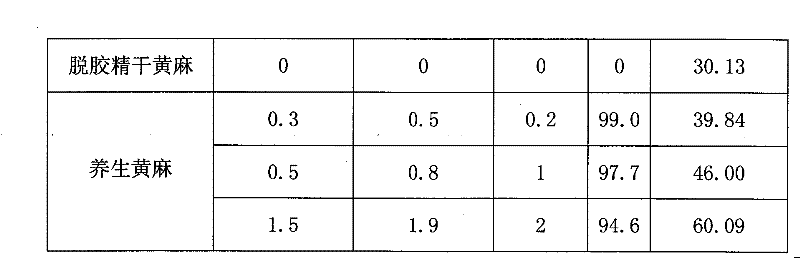

[0031] The comparison of the rewinding degree of healthy jute fiber and degummed refined jute fiber is as follows:

[0032] Table 1

[0033]

[0034]

[0035] As can be seen from Table 1, the spoolability (used to represent softness) of the treated jute fiber without health treatment has been improved by 32.2%-99.4%, which can improve spinning performance .

Embodiment 2

[0037] The comparison of the physical and mechanical properties of the healthy jute fiber and the degummed jute fiber is as follows:

[0038] Table 1

[0039]

[0040] As can be seen from Table 1, after the health-preserving treatment, the strength of the health-preserving jute fiber is 2.56% lower than that of the degummed refined jute, and the elongation at break is 3.88% higher than that of the degummed jute fiber.

Embodiment 3

[0042] Spun into the health-preserving jute blended yarn whose yarn fineness is 27.8tex, its main technical indicators are as follows:

[0043] Table 1

[0044]

[0045] As can be seen from Table 1, the health-care jute fiber blended yarn of finer 27.8tex can be normally produced by adopting the technical scheme of the present invention, and when the jute percentage of the prior art accounts for 55%, only 50tex can be spun The fineness of the yarn was reduced by 44.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com