Physical refinement jhouta blended yarn and preparation method thereof

A technology of refined jute and blended yarn, which is applied in yarn, fiber processing, textiles and papermaking, etc., can solve the problems of coarse jute fiber, poor fiber cohesion, and inability to spin pure jute raw sliver, so as to improve The cohesion force and the effect of improving the fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

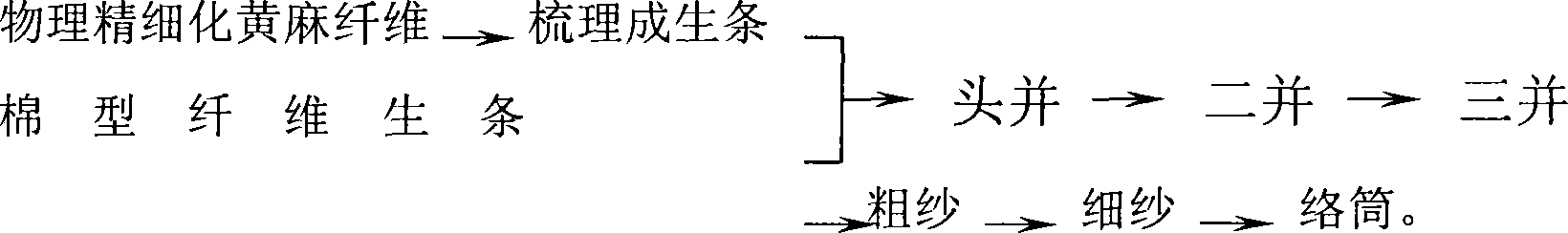

Method used

Image

Examples

Embodiment 1

[0042] The comparison of the windability of softened and refined jute fiber and degummed refined jute fiber is as follows:

[0043] Table 1

[0044]

[0045] It can be seen from Table 1 that the spoolability of the softened and refined jute fiber after treatment is 102.7%-128.2% higher than that of the degummed refined jute fiber without softening treatment.

Embodiment 2

[0047] The impact of physical and mechanical properties of jute fiber after physical refinement is shown in the following table:

[0048] Table 1

[0049] Treatment process

[0050] It can be seen from Table 1 that after the health-preserving treatment, the strength of physically refined jute fibers is 9.62% lower than that of degummed refined jute fibers, and the elongation at break is 11.63% lower than that of degummed refined jute fibers, but the fineness is higher than that of degummed refined jute fibers. up 40.91%.

Embodiment 3

[0052] Spun into different proportions of physically refined jute blended yarns with a fineness of 27.8tex, its main test performance indicators are as follows:

[0053] Table 1

[0054] Yarn Type

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com