Wood drying device

A wood drying and wood technology, applied in the direction of drying gas arrangement, heating device, drying solid materials, etc., can solve the problems of unavoidable bending deformation and radial cracking, unsuitable for small diameter logs, etc., to overcome continuous vacuum drying and intermittent vacuum Effects of drying, avoiding drying defects, and large heat release coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

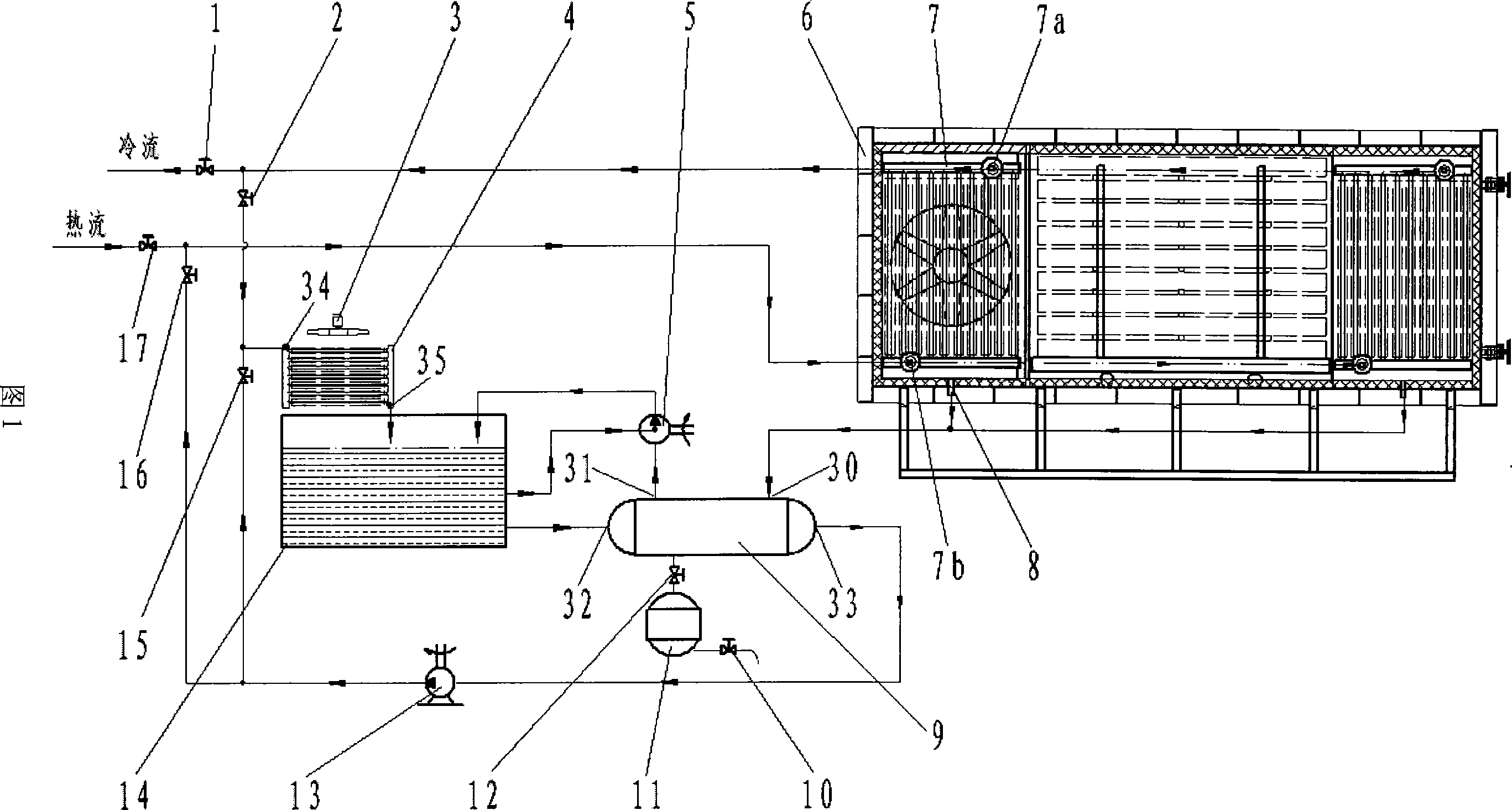

[0030] As shown in Figure 1, the drying equipment of the present invention consists of a drying device, a heating and cooling system, a vacuum condensation system, and a cooling water circulation system.

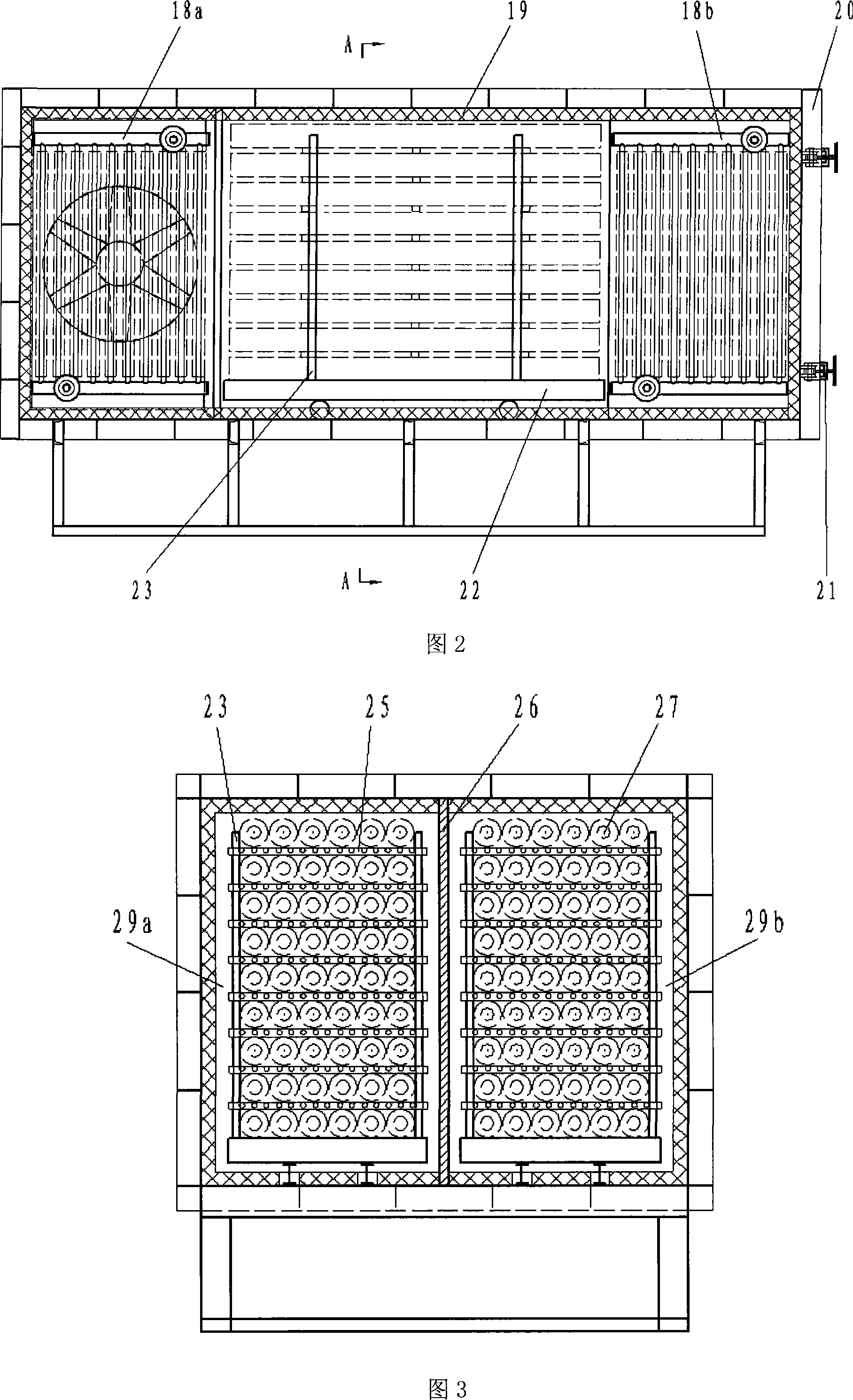

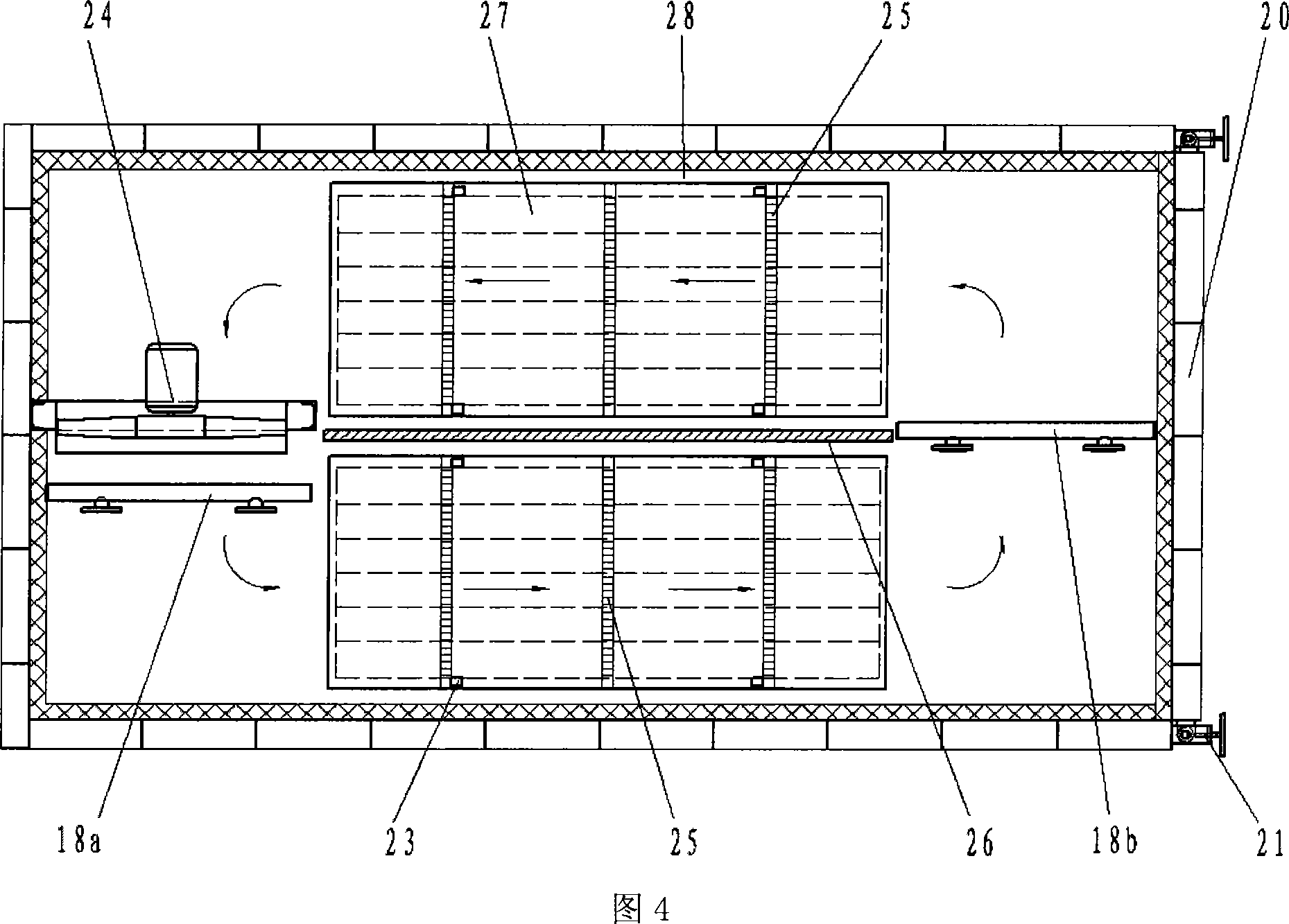

[0031] With reference to Fig. 2,3 and 4, drying device has body 6, and the inwall of body 6 establishes insulating layer 19, and inside forms the cavity that section is rectangle, and one end of cavity is closed, and the other end establishes the closed door 20 that can open and close. The inner cavity of the body 6 includes three parts arranged longitudinally, as shown in Figures 2 and 4, including the middle part of the material section 28, the space between the material section 28 and the closed end, and the space between the material section 28 and the closed door 20. space between.

[0032] Wherein, the material loading section 28 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com