Axial direction free spin device

A rotating device and free technology, applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve the problems of affecting the measurement effect, suspension frame skew, bearing wear, etc., to achieve obvious functional practicability, simplified components, and structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Biaxial rotation type

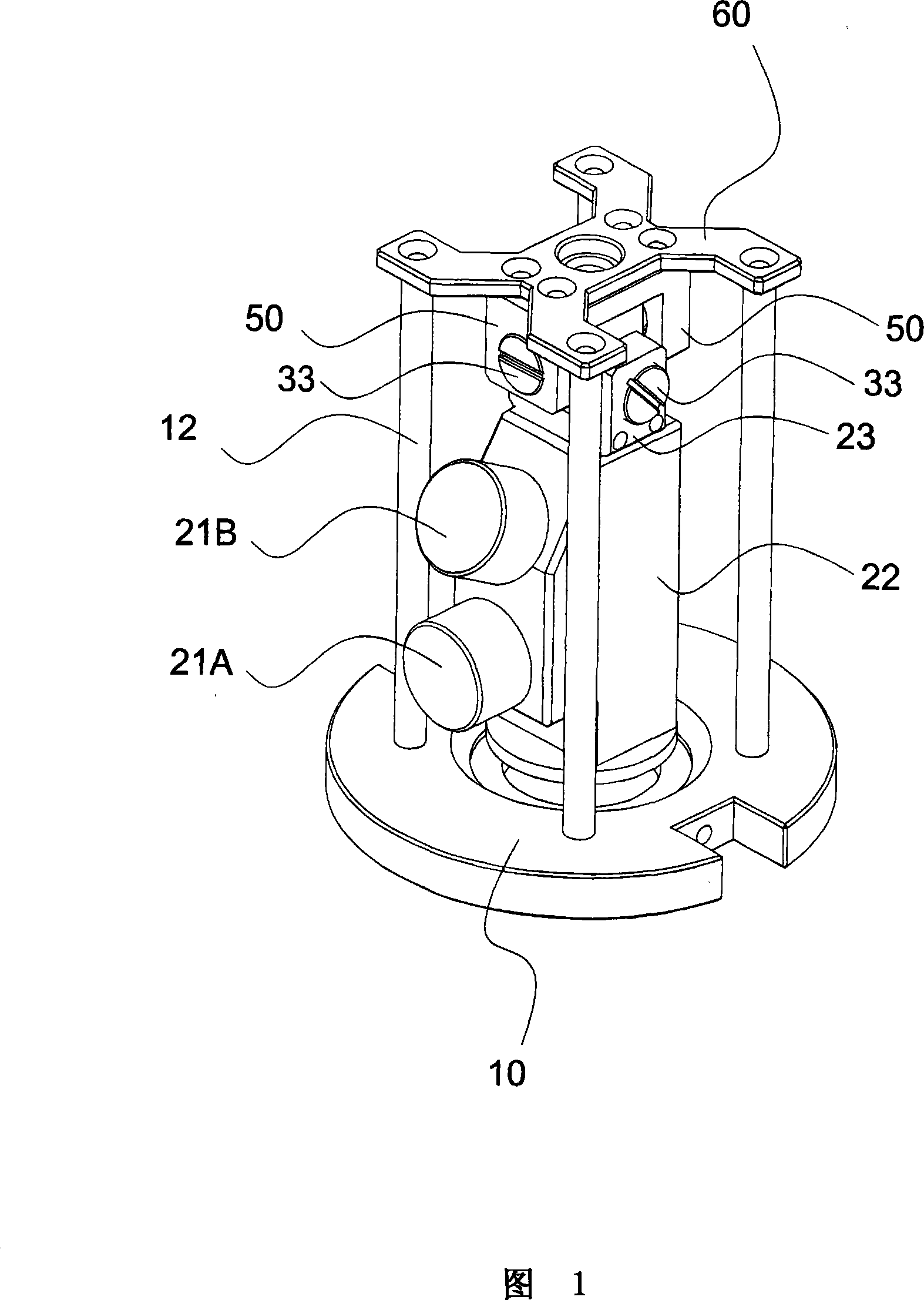

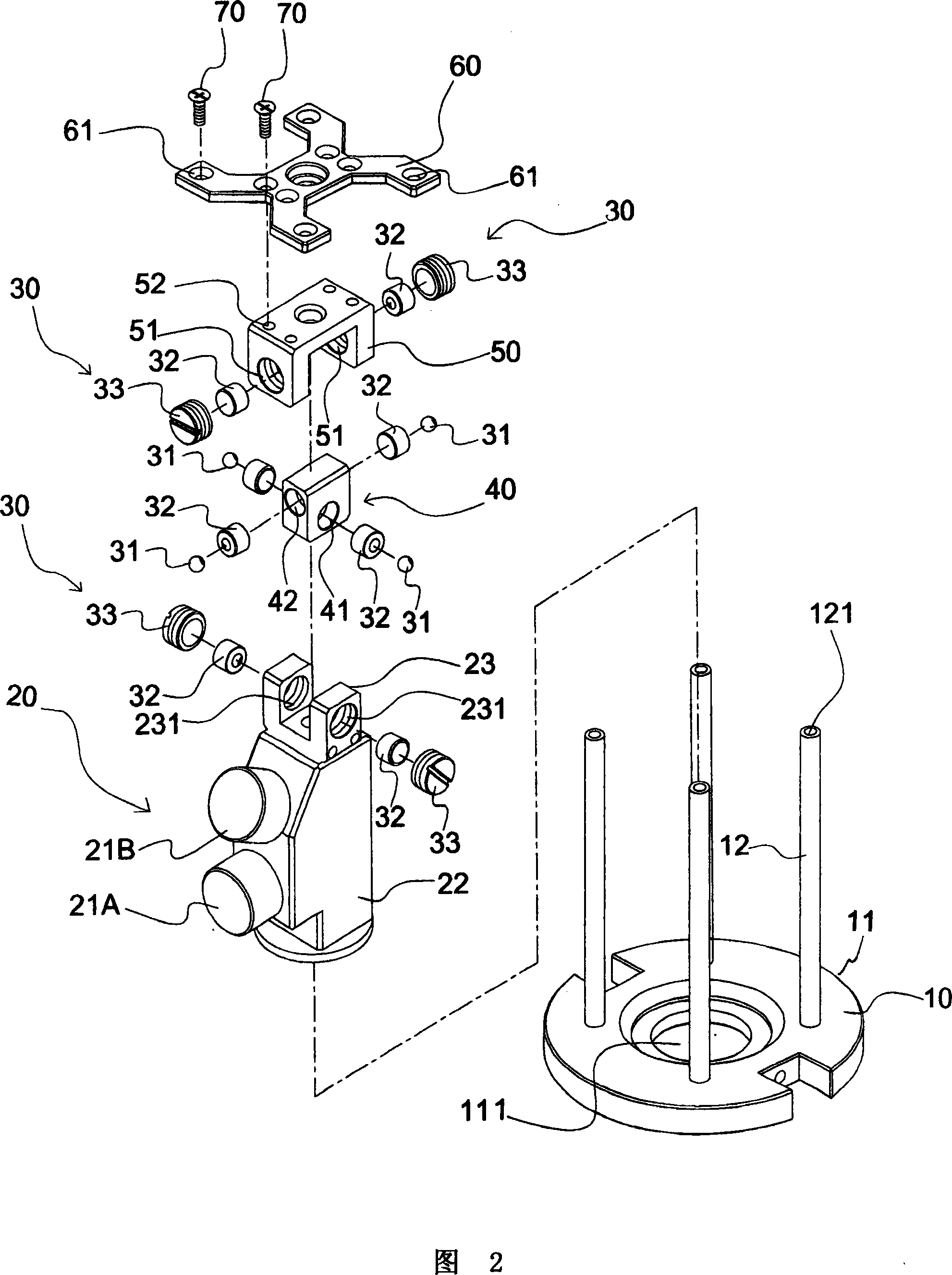

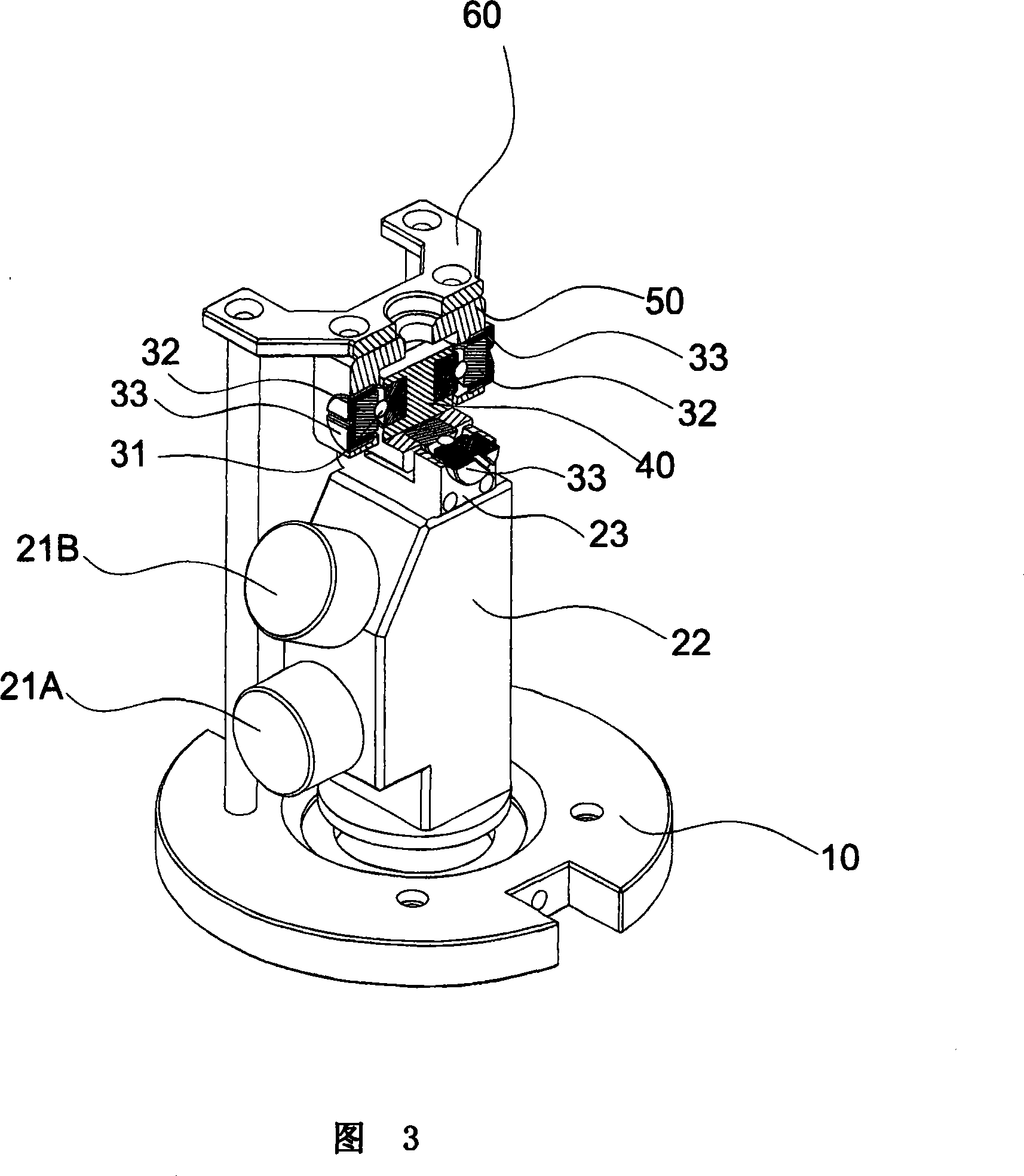

[0038] What Fig. 1-8 shows is the first embodiment of the axial free rotation device of the present invention, in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the axial free rotation device of the present invention comprises: a by above There is a circular base 11 with a step-shaped central pair of perforations 111, four uprights 12 arranged in a rectangular shape, each with a mounting screw hole 121 on the top, and a fixed member 10 composed of a fixed mounting piece 60 for assembly and connection; One includes a main body 22, two laser modules 21 located on the side of the main body 22, consisting of a horizontal laser module 21A and a vertical laser module 21B, and a horizontal through screw hole 231 coaxially arranged on the left and right sides The laser assembly 20 of the top U-shaped piece 23; one left and right sides are provided with a coaxial not penetrating transverse hole 41, and the front and rear sides are provided with a coaxial...

Embodiment 2

[0043] Embodiment 2 single-axis rotation type

[0044] 9-13 show the second embodiment of the axial free rotation device of the present invention, the single axial rotation type axial free rotation device. Its main feature is that the U-shaped part 23 in Embodiment 1 is removed, the swing member 40, the rolling member 30 are reduced from the original four groups to two groups, and the laser module 21 is reduced from the original two groups to one group (that is, only A vertical or horizontal laser module 21C) is set, and the top of the main body 22 of the laser assembly 20 is provided with a protruding shaft member 24 that is coaxially recessed on the front and rear sides and does not penetrate the longitudinal hole 241, so as to install the rolling members correspondingly The single-end concave cylinder 32 in 30 is not penetrated in the longitudinal hole 241, and the spherical ball 31 in the rolling member 30 is arranged on the outer concave surface of the single-end concave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com