High-speed curved printer capable of checking edition automatically

A curved printing machine, high-speed technology, applied in printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problem of inability to realize automatic color registration and other problems, and achieve the effect of scientific structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

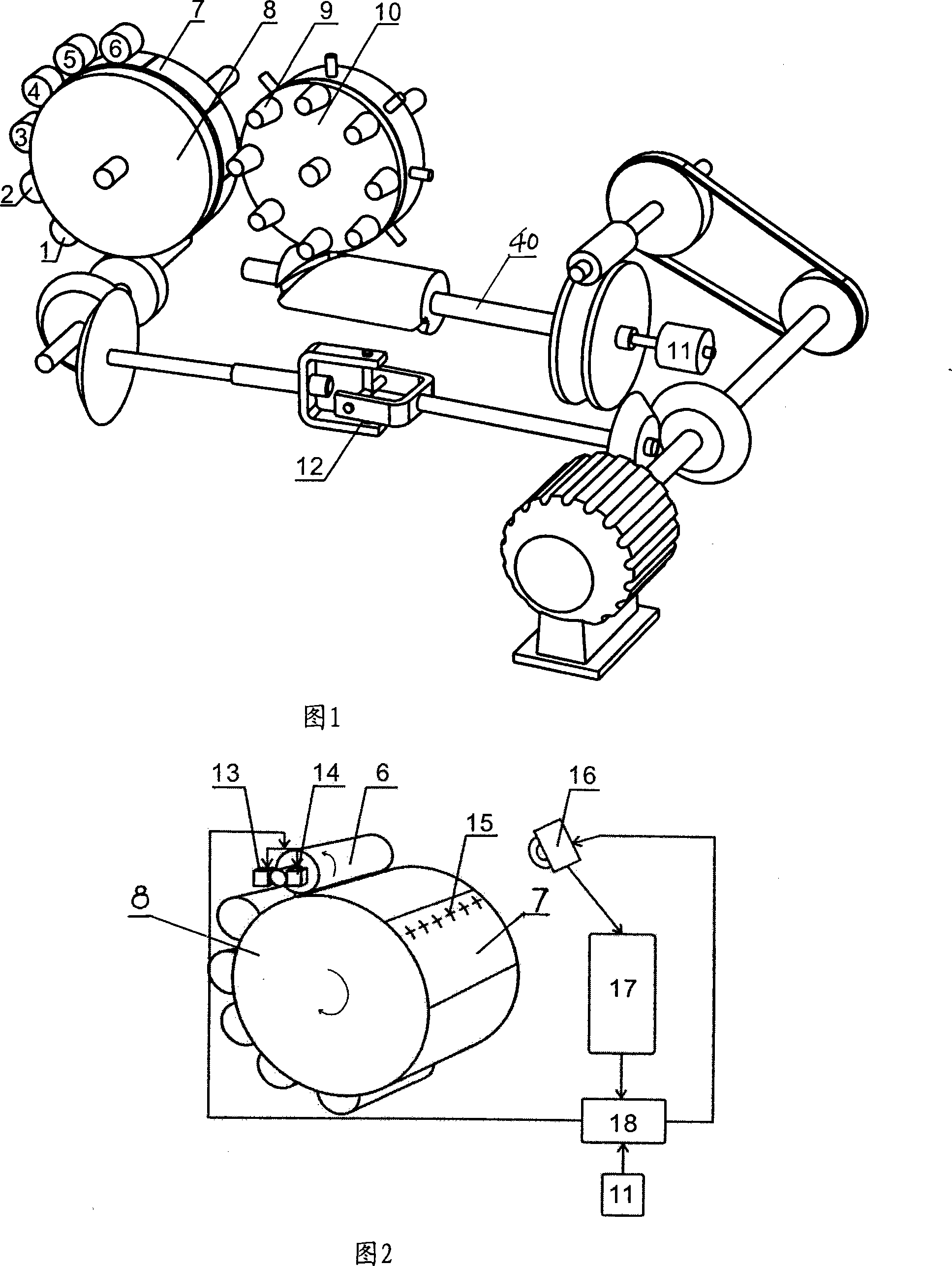

[0013] Figure 1 shows the structural schematic diagram of the entire curved surface printing machine. The entire curved surface printing machine is driven by a motor. When the motor is started, part of the movement of the motor drive shaft is transmitted to the large rubber roller through the drive shaft with universal coupling 12 8. The other part is transmitted to the material tray 10 through the pulley and the camshaft 40, and the motor transmission shaft, the transmission shaft with the universal joint 12 and the camshaft 40 rotate synchronously (that is, the transmission ratio between them is 1), The motor transmission shaft, the transmission shaft with the universal joint 12 and the camshaft 40 are collectively referred to as the main transmission shaft system, and the transmission ratio of the main transmission shaft to the large rubber roller and the material tray is 8:2:1.

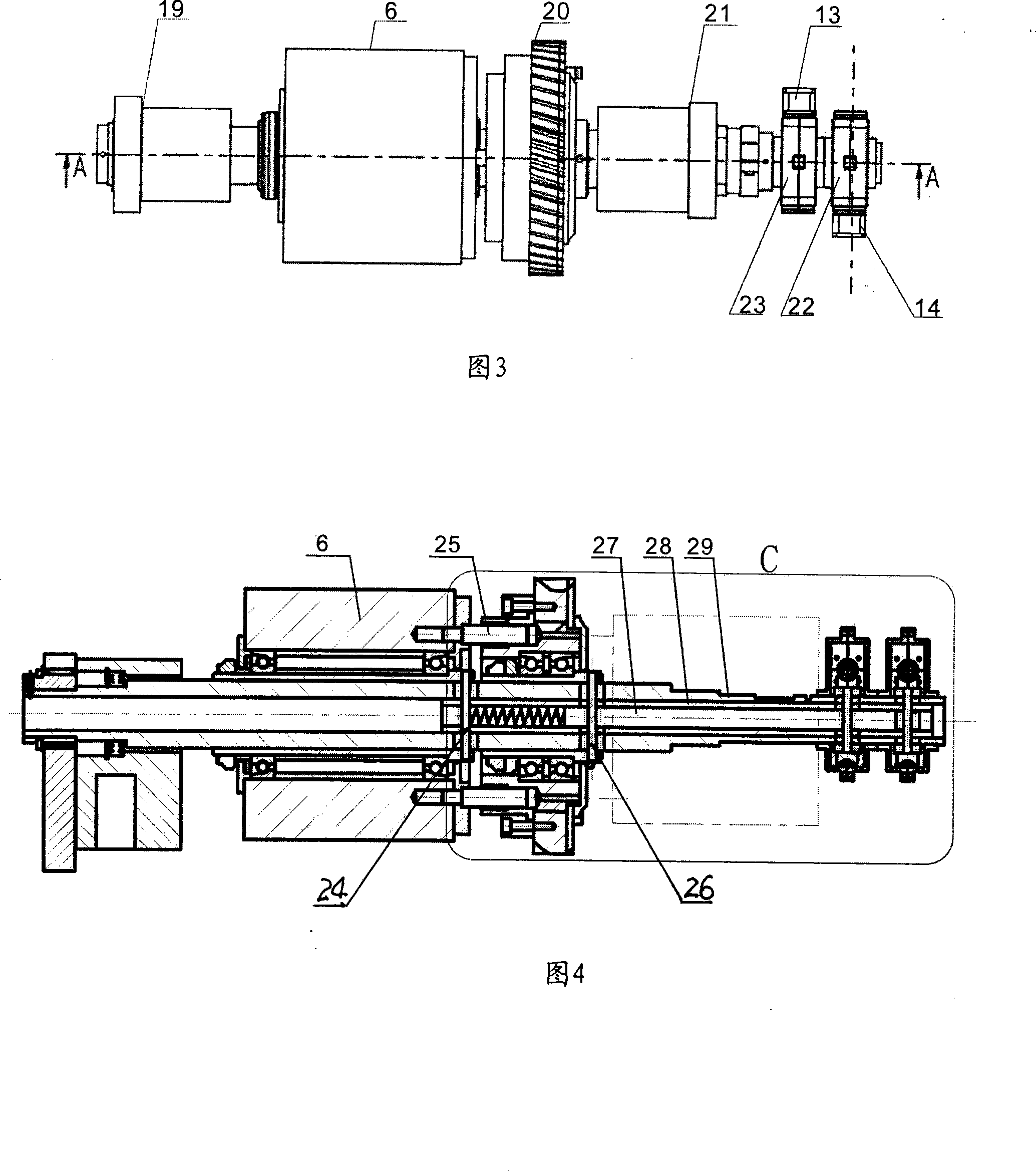

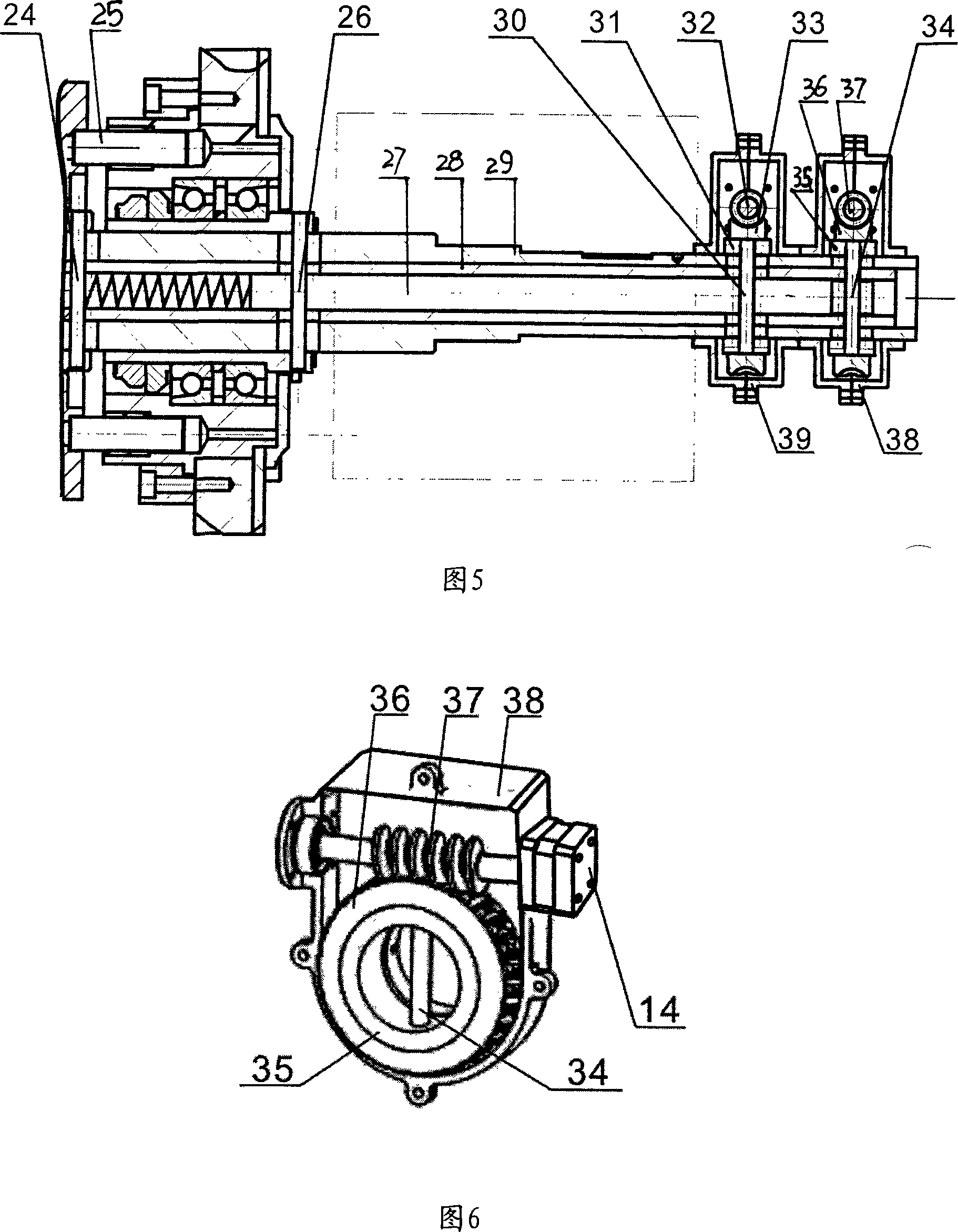

[0014] A high-speed curved surface printing machine capable of automatic plate alignment, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com