Packing case

A packaging box and box body technology, which is applied in the field of packaging boxes for flat display panels, can solve the problems of high packaging costs, waste of resources, damage, etc., and achieve the effect of facilitating assembly operations and preventing malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

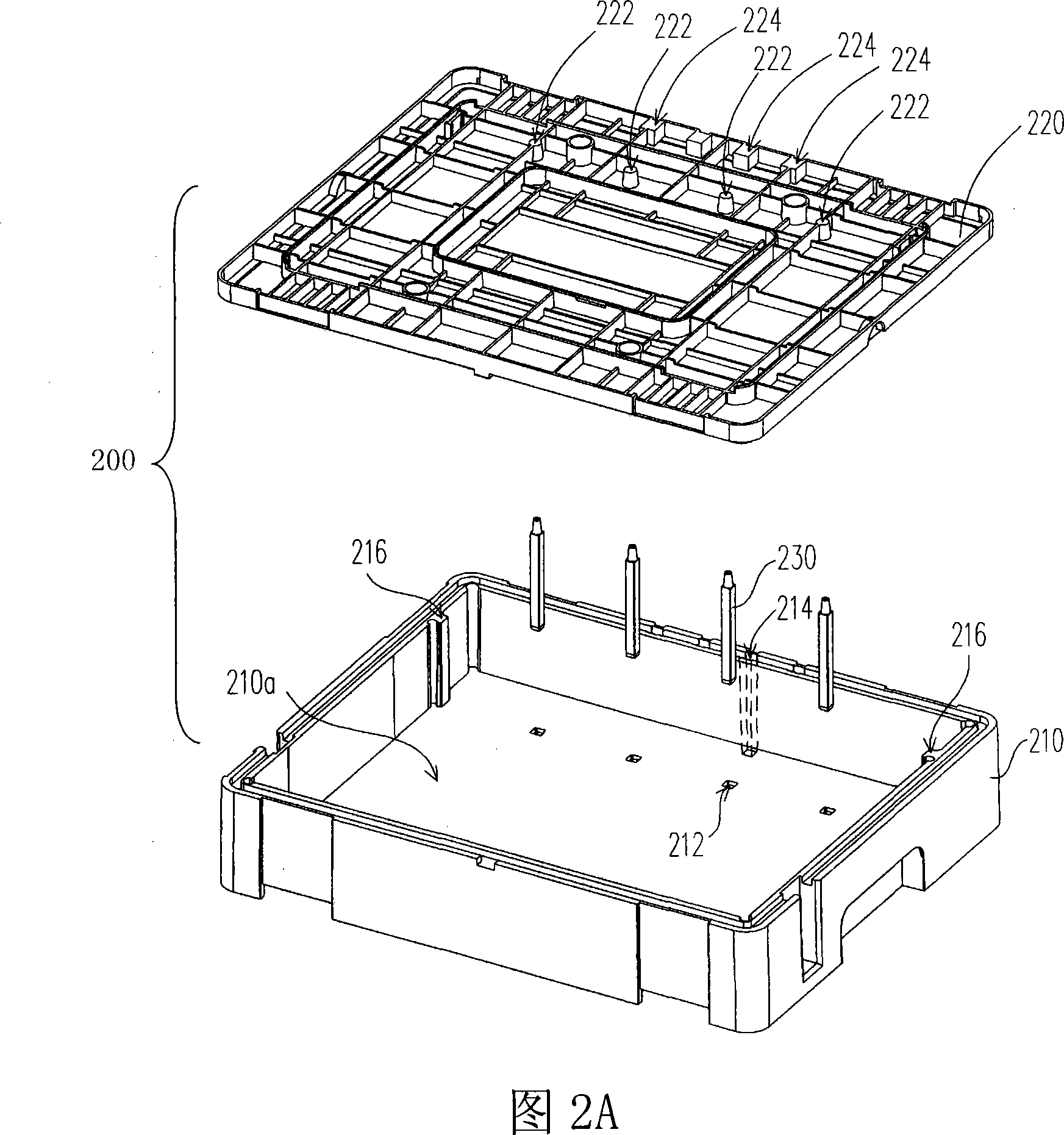

[0061] Fig. 2A is a schematic diagram of a packing box according to the first embodiment of the present invention. Please refer to FIG. 2A , the packing box 200 is suitable for storing a plurality of flat display panels (shown in FIG. 3 ), wherein the flat display panels are, for example, liquid crystal display panels, organic light emitting diode panels, electrowetting display panels, plasma display panels, or Other types of flat display panels. The packaging box 200 is mainly composed of a box body 210 , a cover body 220 and at least one support pin 230 . The bottom of the box body 210 has at least one first assembly hole 212 , and the side wall of the box body 210 has at least one first pin receiving space 214 and a set of supporting ribs 216 protruding inward from the side wall. In this embodiment, the first pin receiving space 214 extends from the top of the side wall toward the bottom of the box body 210 .

[0062] FIG. 2B is a top view of the cover in FIG. 2A , and FI...

no. 2 example

[0079] Fig. 6 is a schematic diagram of a packing box according to the second embodiment of the present invention. Referring to FIG. 6 , the packing box 300 is suitable for storing a plurality of flat display panels 240 , and each flat display panel 240 is respectively connected to a driving device 242 . The box body 310 is suitable for receiving the flat display panel 240 , wherein the box body 310 has a set of supporting ribs 316 protruding inward from the sidewall. The cover body 320 is adapted to cover the box body 310 . The support pin 330 is located between the box body 310 and the cover body 320 , and the support pin 330 and the support rib 316 jointly support the flat display panel 240 .

[0080] As shown in Figure 6, one end of the support pin 330 is fixed on the bottom of the box body 310, and the cover body 320 has an assembly hole 322 corresponding to the support pin 330, so that when the cover body 320 is covered on the box body 310, One end of the support pin 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com