Organic electroluminescent LED manufacturing method and the buffering conversion cavity using the same

A manufacturing method and diode technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem that defects cannot be repaired online, and achieve the effect of reducing dependence and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

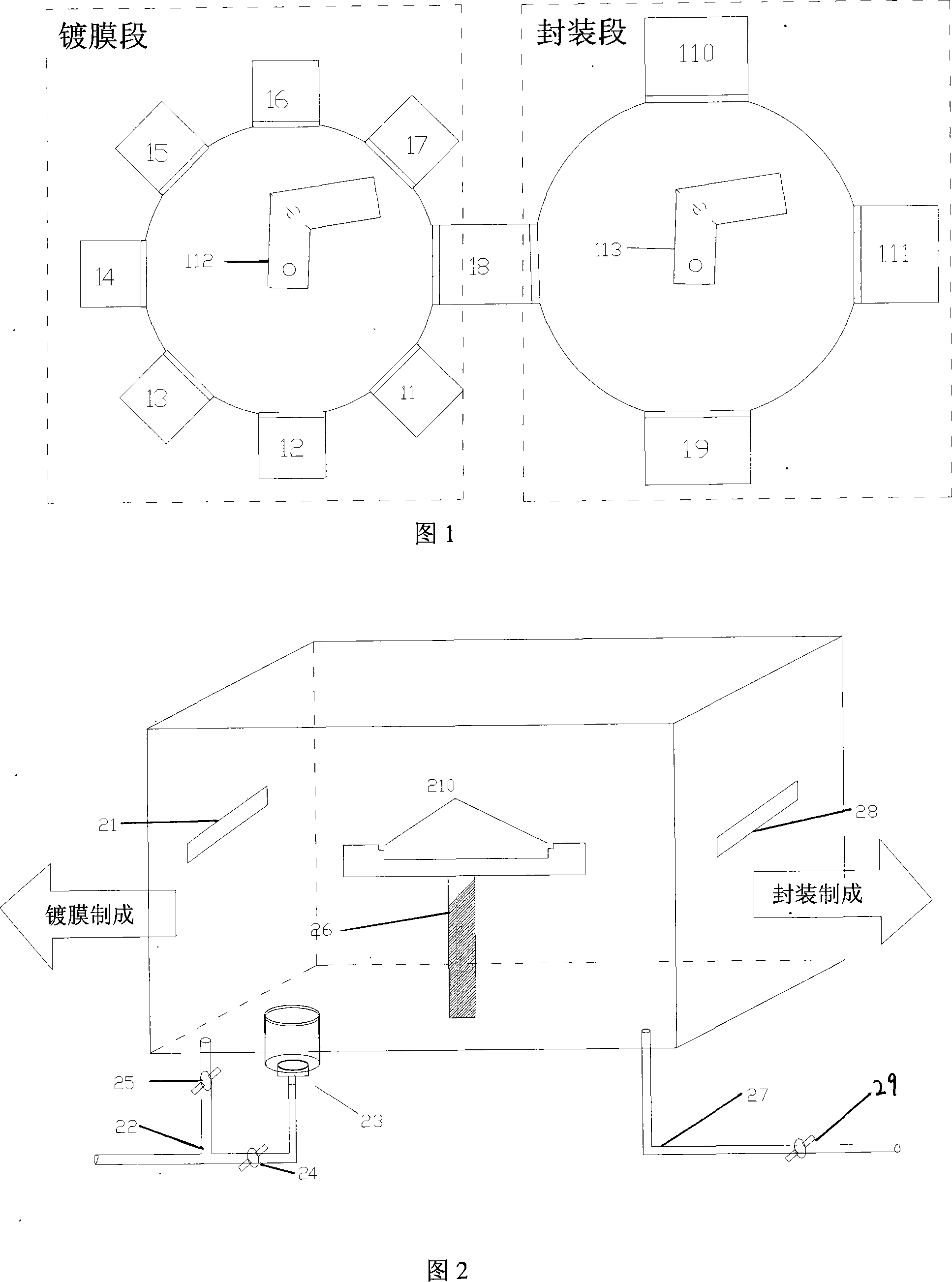

[0023] The OLED manufacturing process is shown in Figure 1. The substrate in the OLED device is used as the support of the organic electroluminescent device. Generally, a glass substrate or a plastic substrate is used. The glass substrate can be made of lime soda glass or borosilicate glass, and the plastic substrate can be polyester. or polyimide compounds. The anode is a transparent electrode, which is made on the substrate and can be made of inorganic materials or conductive polymer materials. The inorganic materials are generally indium tin oxide (ITO) or indium zinc oxide (IZO), or gold, copper, silver, etc. High-function metal.

[0024] The ITO is carved into strips for use as a light-emitting anode, and a layer of non-conductive organic resin material (commonly used PSPI) is formed on the substrate by spin coating in the ITO direction and perpendicular to the ITO direction. form the desired pattern. At the same time, a layer of negative organic resin material is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com