Plasticiser for phenolic foam, and a process for producing phenolic foam

A technology of phenolic foam and plasticizer, which is applied to the plasticizer for phenolic foam, can solve the problems of unsatisfactory degradation of foam wall time, failure to achieve foam insulation stability, etc., to inhibit degradation and improve long-term The effect of adiabatic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

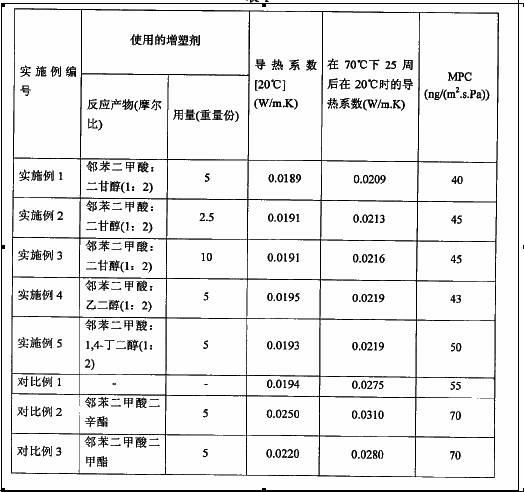

[0072] Polyester polyols are obtained by reacting phthalic acid with diethylene glycol at a molar ratio of 1:2. The weight average molecular weight of the polyester polyol thus obtained is 450-500. To 103 parts by weight of a resol resin PF-328 (manufactured by Asahi Organic Chemicals Industry Co Ltd), 5 parts by weight of this polyester polyol was added and mixed. The PF-328 resin comprises 100 parts by weight of resole resin prepared by reacting phenol and formaldehyde at a molar ratio of 1:2.0, and then 3 parts by weight of silicone oil surfactant is mixed thereinto to complete the PF-328 resin mixture.

[0073] Add 8 parts by weight of pentane as foaming agent in the phenolic resin mixture obtained, and pump 20 parts by weight of p-toluenesulfonic acid and xylenesulfonic acid (weight ratio is 2: 1) in the mixer The mixture acts as a catalyst to obtain a foamable phenolic resin composition. The composition was poured into a formwork lined with a glass fiber nonwoven. Foa...

Embodiment 2

[0075] A sample of the phenolic foam was prepared in the same manner as in Example 1, except that the amount of the polyester polyol was changed to 2.5 parts by weight based on the weight of the phenolic resin. The properties of the foam are shown in Table 1.

Embodiment 3

[0077] A sample of the phenolic foam was prepared in the same manner as in Example 1, except that the amount of the polyester polyol was changed to 10 parts by weight based on the weight of the phenolic resin.

[0078] The properties of the foam are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com