Method for preparing small spherical Pd catalyst

A catalyst and pellet technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of troublesome catalyst separation, unstable product hydrogenation degree, etc. Hydrogen characteristics and effects of stability control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Put the macroporous finished silica gel pellets into a buffer solution composed of C.P grade glacial acetic acid, C.P grade ammonium acetate and pure water after vacuum drying. The pH value of the buffer solution is equal to 4.9-5.1. The buffer solution and The volume ratio of the silica gel pellets is 2:1. Under nitrogen bubbling, keep warm at 45°C. After 72 hours, wash the silica gel pellets with deionized water until neutral, filter the silica gel pellets, and dry them in vacuum. (2) Submerge the dried silica gel pellets in palladium dichloride-hydrochloric acid solution. The solution is mixed with C.P grade concentrated hydrochloric acid and C.P grade palladium dichloride, and their weight ratio is 20:1. After the palladium dichloride is completely dissolved, it is diluted to 100:1 with 2M hydrochloric acid. Stand at normal temperature and pressure for 70 hours, stir once an hour, and filter out the pellets. (3) Put the filtered pellets into ammonia water with...

Embodiment 2

[0032] Except that the palladium dichloride was completely dissolved in step (2), and then diluted to 300:1 with 2M hydrochloric acid, other conditions were the same as in Example 1. As a result, the small spherical Pd catalyst obtained has physical and chemical indicators: the weight percent of Pd: 0.1, and the specific surface area is 160--190m 2 / g, the pore volume is 0.546cm 3 / g, the most possible aperture D is equal to 112.5 , particle size 4.5-5.8mm, internal pressure strength (average value) ≥ 6kg / particle.

Embodiment 3

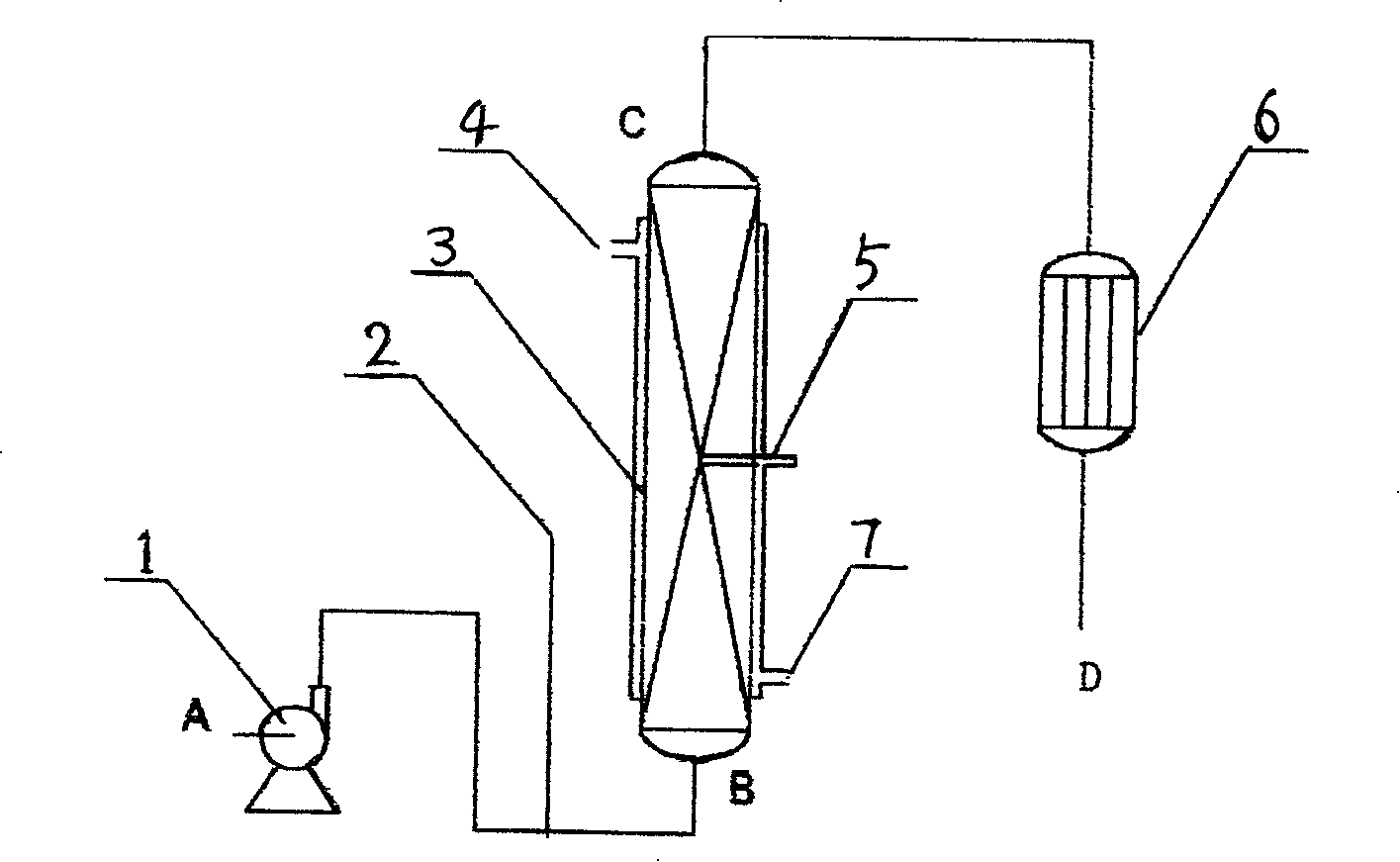

[0034] Synthesis of 1,4-butanediol in a fixed bed reactor. device attached figure 1 As shown, the fixed bed reactor [3] is composed of a stainless steel tube (1Cr18Ni9Ti) with a length of Ф32 mm, a length of 300 mm, and a wall thickness of 3 mm. Outflow from the cooling water outlet [4] behind the outer jacket. After filling the prepared small spherical Pd catalyst, it can be used. (Design pressure is 1.6MPa)

[0035] The hydrogenation raw material 1,4-butynediol is fed into the quantitative pump [1] from the A end, and after being heated by the tube wall, it is injected into the B end of the bottom of the reactor [3]. Hydrogen enters reactor [3] bottom B end by hydrogen inlet [2], and after mixing with 1,4-butynediol, hydrogenation is carried out under the catalysis of 30 grams of small spherical Pd catalysts prepared under the conditions of Example 1 Reaction, the 1,4-butanediol that generates overflows from the C end of the top of the reactor [3], and is collected at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com