Porous carbon supported platinum-cerium oxide catalyst for fuel cell and preparation thereof

A fuel cell and cerium oxide technology, applied in the field of porous carbon-supported platinum-cerium oxide composite catalyst and its preparation, can solve the problems that the catalyst is easily poisoned, can no longer play a catalytic role, lose activity, etc., and achieve excellent anti-poisoning performance, Excellent antioxidant properties, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

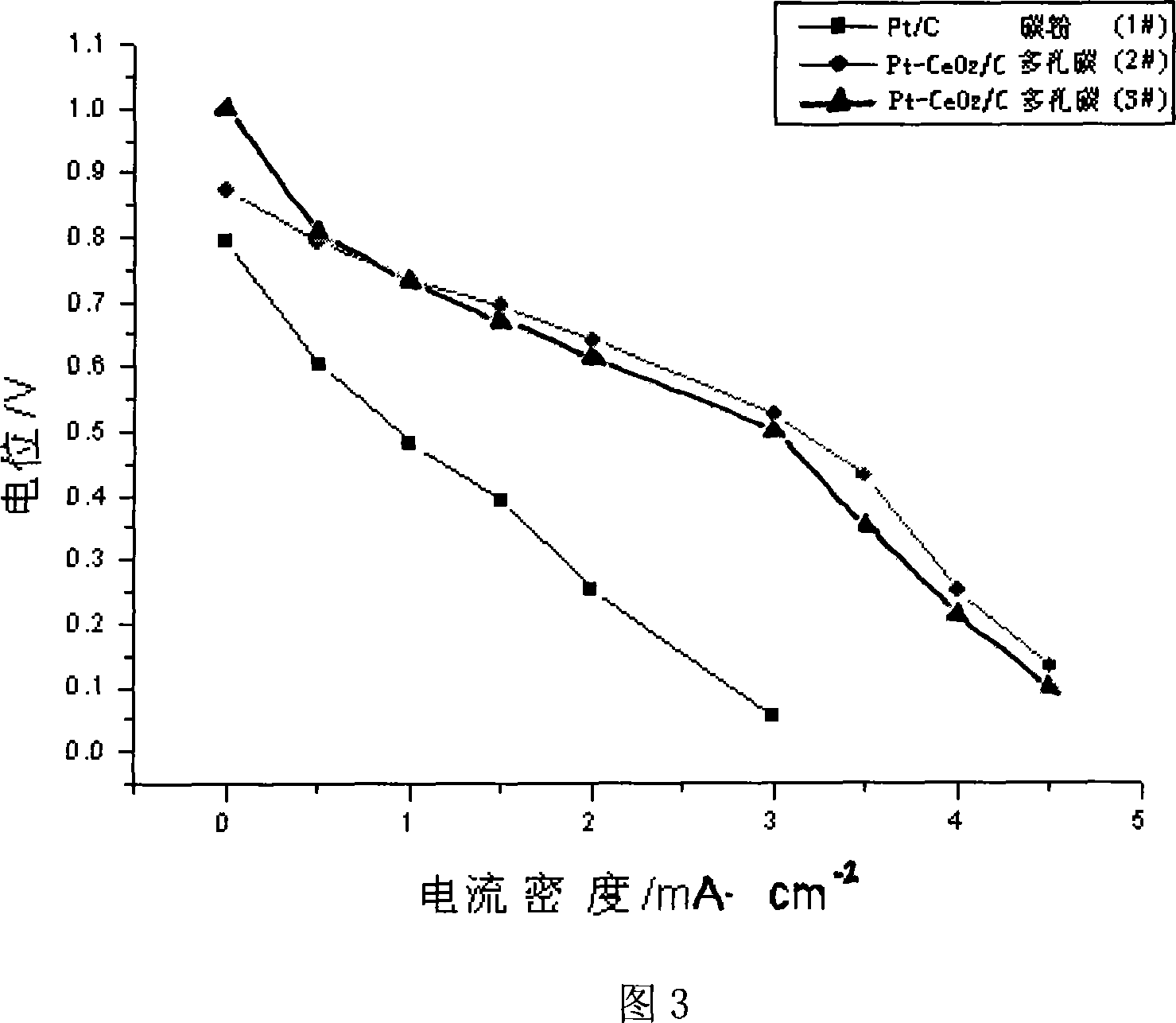

Embodiment 1

[0024] Weigh 0.9g porous carbon powder in acetone, concentrated HNO 3 solution, heated to reflux for 1 hour. Filter, wash with deionized water to pH = 6, and dry at a constant temperature of 110°C; place the treated porous carbon powder in a beaker, add isopropanol and water, and then add cerium ammonium nitrate solution (the amount is based on the final cerium oxide accounted for porous carbon powder). 10% of the weight of cerium oxide), fully mixed uniformly in the ultrasonic wave, added excessive sodium hydroxide solution to the system, so that the pH value was 8-9, soaked for 4-6 hours, and suction filtered and washed after the reaction was completed, 80 °C for 12 hours in vacuum, then put the product in a tube furnace and calcined under the protection of N2, and calcined at 300 °C for 3 hours to obtain a porous cerium oxide powder material.

[0025] The obtained cerium oxycarbide material was put into a three-necked flask, and absolute ethanol, water and isopropanol were...

Embodiment 2

[0032] Weigh 0.8g porous carbon powder in acetone, concentrated HNO 3 solution, heated to reflux for 1 hour. Filter, wash with deionized water to pH = 6, and dry at a constant temperature of 100°C; place the treated porous carbon powder in a beaker, add isopropanol and water, and then add cerium ammonium nitrate solution (the amount is based on the final cerium oxide accounted for porous carbon powder). 20% of the weight of cerium oxide), fully mixed uniformly in the ultrasonic wave, added excessive sodium hydroxide solution to the system, so that the pH value was 8-9, soaked for 4-6 hours, and suction filtered and washed after the reaction was completed, 90 ℃ vacuum drying for 11 hours, and then the product was placed in a tube furnace under N 2 Calcination under protection, calcination at 400°C for 2 hours, a porous cerium oxide powder material.

[0033] The platinum loading method is the same as that of embodiment 1, and the platinum loading of the prepared catalyst is 30...

Embodiment 3

[0036] Weigh 0.9g porous carbon powder in acetone, concentrated HNO 3 solution, heated to reflux for 2 hours. Filter, wash with deionized water to pH = 6, and dry at a constant temperature of 120°C; place the treated Vulcan XC-72 carbon powder in a beaker, add isopropanol and water, and then add cerium ammonium nitrate solution (the amount added is based on the final oxidation Cerium accounts for 10% of the weight of cerium oxycarbide), fully mixed uniformly in the ultrasonic wave, and excessive sodium hydroxide solution is added to the system to make the pH value at 8-9, soak for 4-6 hours, and perform suction filtration and washing after the reaction is completed , dried under vacuum at 70°C for 14 hours, and then placed the product in a tube furnace under N 2 Calcination under protection, calcination at 200°C for 4 hours, a porous cerium oxide powder material.

[0037] The platinum loading method is the same as that of embodiment 1, and the platinum loading of the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com