High temperature resistant high photics reflexive conductive film and preparation method thereof

A technology of optical reflection and conductive film, applied in chemical instruments and methods, optics, optical components, etc., can solve the problems of structural damage, agglomeration and agglomeration, conduction failure of silver film, and achieve high optical reflection performance and good electrical conductivity. , Overcome the effects of agglomeration and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

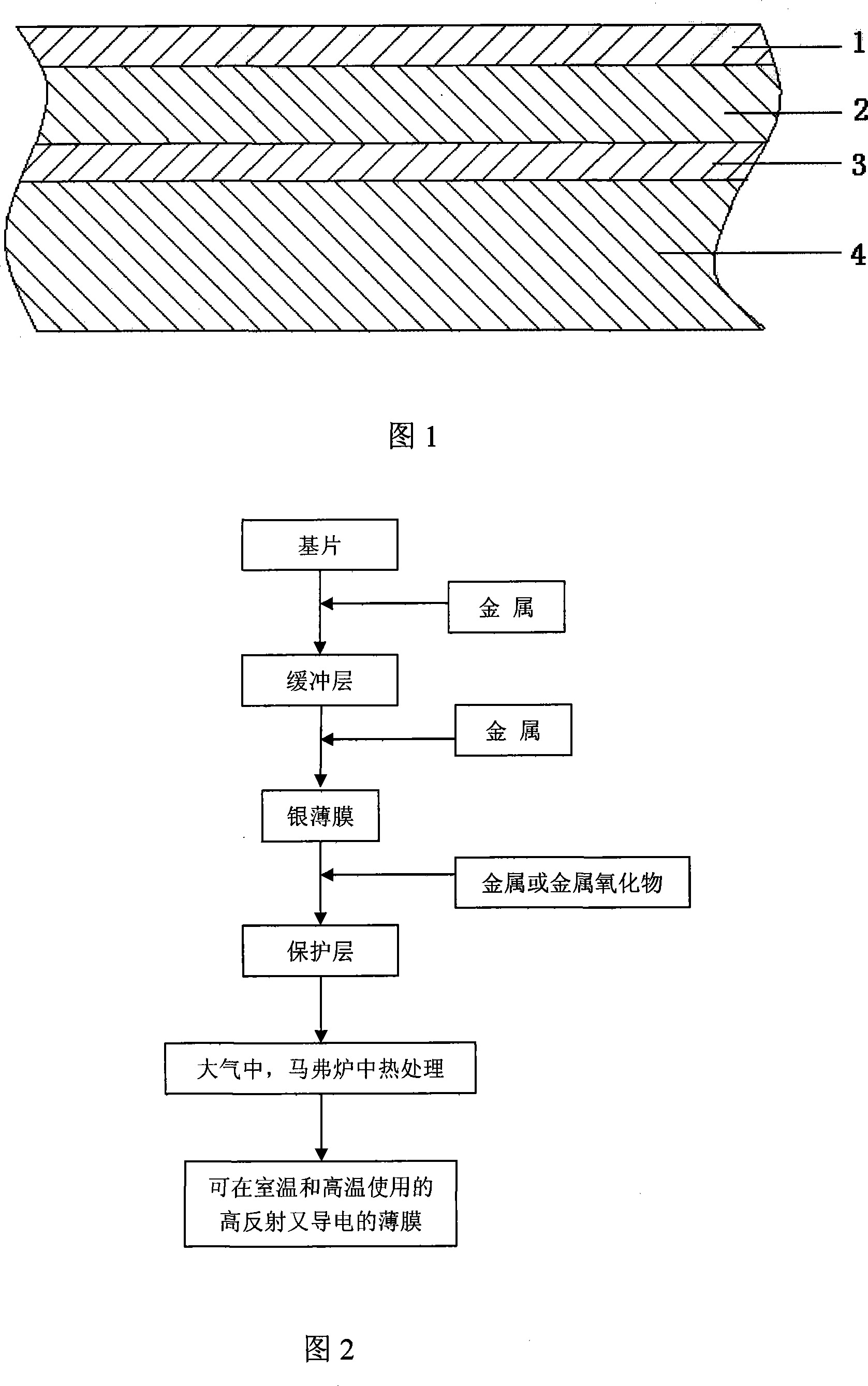

[0028] It includes a base layer 4; a thin film buffer layer 3 arranged on the base layer 4; a thin film conductive layer 2 attached to the buffer layer 3; and a thin film protective layer 1 attached to the thin film conductive layer 2. Wherein: the base layer material is quartz; the buffer layer material is aluminum thin film, the thin film conductive layer material is silver, and the thin film protective layer material is silicon oxide.

[0029] 1. Preparation of thin film buffer layer

[0030] The aluminum thin film was deposited on the quartz substrate by magnetron sputtering, the film thickness was 30 nanometers, the sputtering target material was metal aluminum, the sputtering power was 100 watts, and the sputtering gas pressure was 0.9 Pa.

[0031] 2. Preparation of thin film conductive layer silver

[0032] Using magnetron sputtering to deposit a metallic silver film on the surface deposited with the aluminum film, the thickness of the silver film is 250 nm, the sputte...

Embodiment 2

[0038] It includes a base layer 4 ; a thin film buffer layer 3 arranged on the substrate 4 ; a thin film conductive layer 2 attached to the buffer layer 3 ; Wherein: the base layer material is single crystal silicon wafer; the buffer layer material is aluminum and copper mixed film, the film conductive layer material is silver, and the film protective layer material is zinc oxide film.

[0039] 1. Preparation of thin film buffer layer

[0040] A mixed film of copper and aluminum was deposited on a single crystal silicon substrate by magnetron sputtering. The thickness of the film was 30 nanometers. The sputtering target material was a mixture of metal copper and aluminum. The weight ratio of copper and aluminum was 1:1. The power was 100 watts, and the sputtering gas pressure was 0.9 Pa.

[0041] 2. Preparation of thin film conductive layer silver

[0042] Using magnetron sputtering to deposit a metal silver film on the surface deposited with copper and aluminum mixed film, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com