Special-purpose metal calcium core granular combustion-supporting desulfurization coke cleaning agent for bombardment type coal and preparation method thereof

A technology of metal calcium and coke cleaning agent, which is applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of weak detonation heating capacity, easy to be affected by moisture, and reduced efficacy, and achieve improved burnout rate, obvious efficacy, and improved thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take metal active calcium Ca 10%, calcium oxide Ca by weight 2 o15%, sodium carbonate Na 2 co 3 25%, aluminum oxide Al 2 o 3 10%, pulverized coal 30% and inorganic binder 10%, prepare according to the following steps:

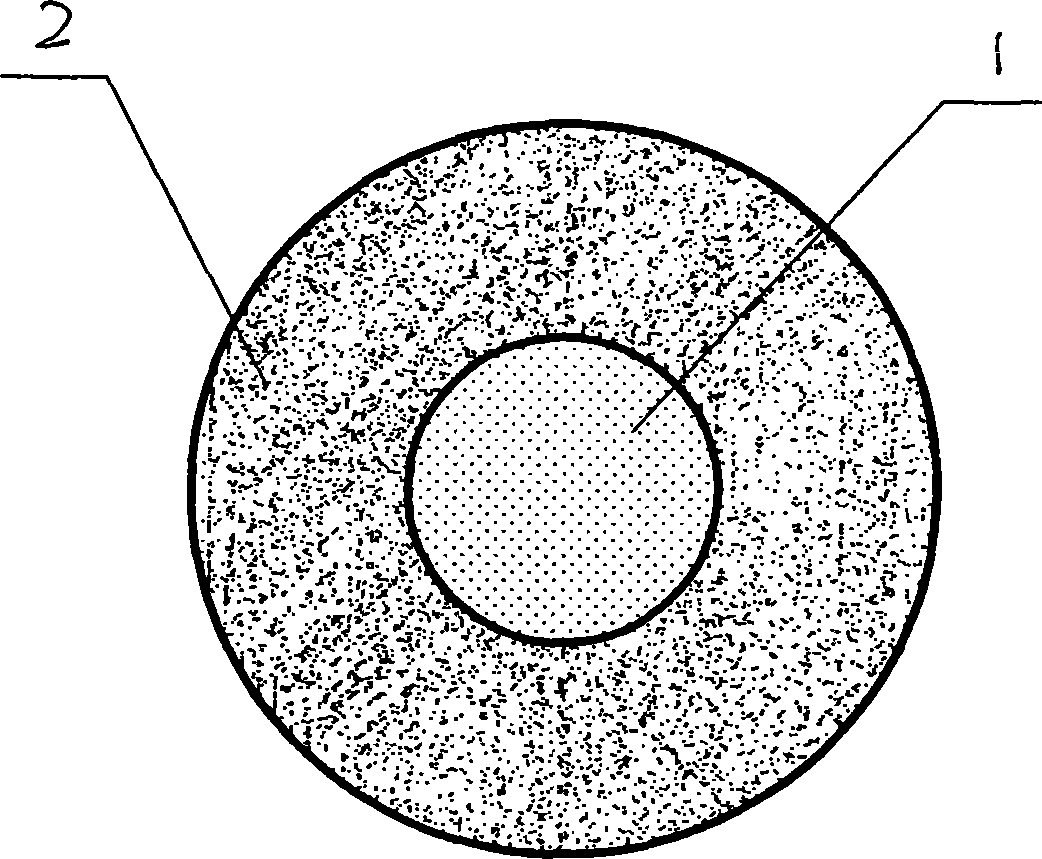

[0025] a. Use granulation equipment to prepare metal active calcium Ca into particles with a diameter of 1.5-2 mm, and spray an anti-oxidation film on the outer layer of the particles as the core of the granular combustion-supporting desulfurization decoking agent, and reserve;

[0026] b. Using powder making equipment to make calcium oxide Ca 2 o Prepared into a powder with a particle size of 120 mesh;

[0027] c, adopt powder making equipment to make sodium carbonate Na 2 co 3 Prepared into a powder with a particle size of 110 mesh;

[0028] d. Using powder making equipment to make Al 2 o 3 Prepared into a powder with a particle size of 90 mesh;

[0029] e, using pulverizing equipment to prepare pulverized coal into a powder with a particle...

Embodiment 2

[0032] Take metal active calcium Ca 8%, calcium oxide Ca by weight 2 o24%, sodium carbonate Na 2 co 3 22%, aluminum oxide Al 2 o 3 8%, pulverized coal 32%, and inorganic binder 6%, were prepared according to the steps described in Example 1.

Embodiment 3

[0034] Take metal active calcium Ca 12%, calcium oxide Ca by weight 2 o20%, sodium carbonate Na 2 co 3 22%, aluminum oxide Al 2 o 3 10%, pulverized coal 28%, and inorganic binder 8%, were prepared according to the steps described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com