Gas dynamic simulation system for steel enterprise

A technology of dynamic simulation and simulation system, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

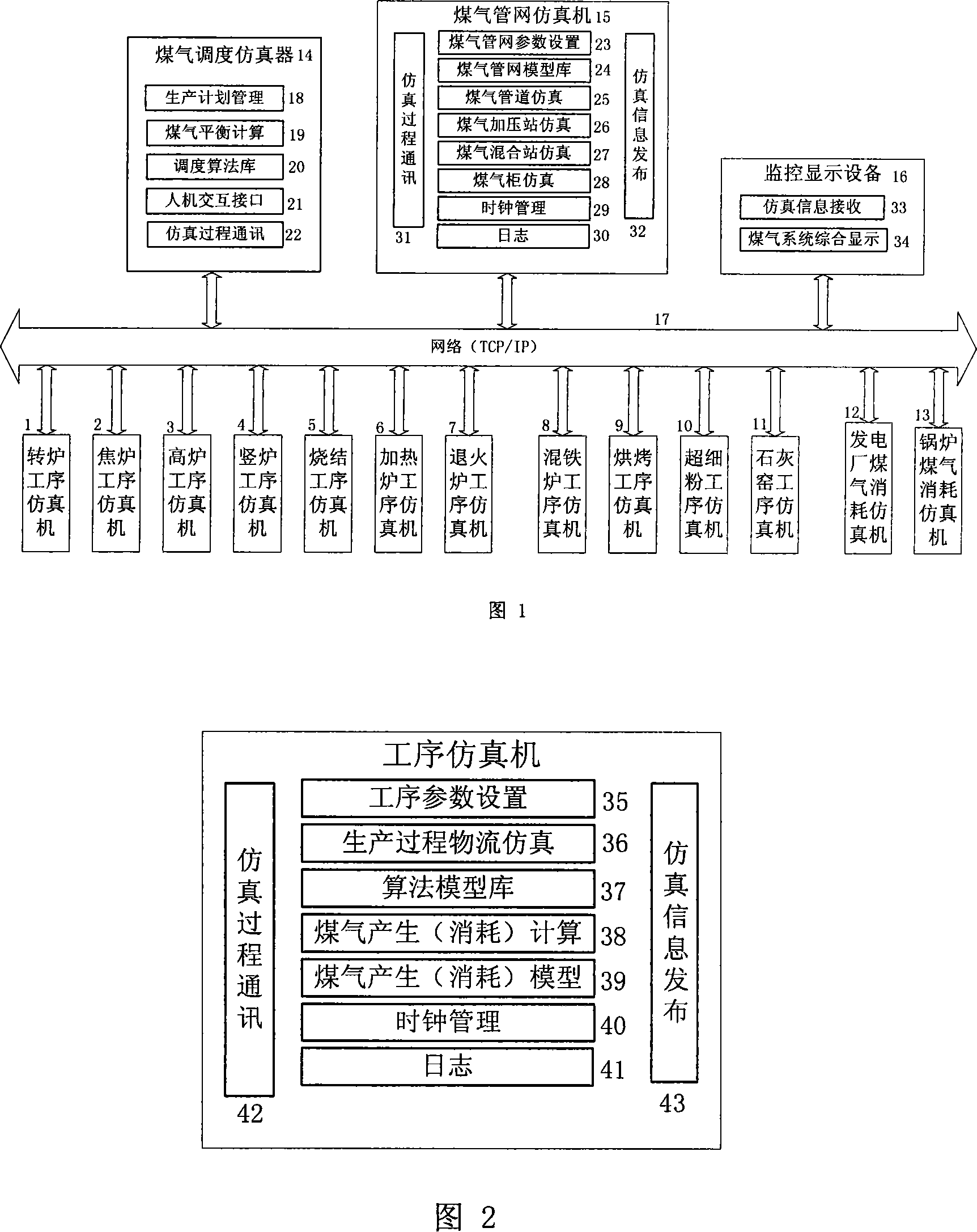

[0023] Firstly, the gas dispatching simulator 14 selects the production plan automatically or by the user through the human-computer interaction interface 21, and sends the production plan to each production process through the simulation process communication 22, including the converter process simulator 1, the coke oven process simulator 2, and the blast furnace process Simulator 3, Shaft Furnace Process Simulator 4, Sintering Process Simulator 5, Heating Furnace Process Simulator 6, Annealing Furnace Process Simulator 7, Mixed Iron Furnace Process Simulator 8, Baking Process Simulator 9, Superfine Powder Process Simulation machine 10, lime kiln process simulation machine 11, power plant gas consumption simulation machine 12 and boiler gas consumption simulation machine 13; each production process receives the production plan of the gas dispatching simulator 14 through the simulation process communication 42, and sets 35 according to the process parameters Determine the respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com