Inductance measuring encapsulation part and its making method

A manufacturing method and packaging technology, which are used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of size limitation, intrusion, cracking and other problems of sensing packages, so as to avoid affecting product life, The effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

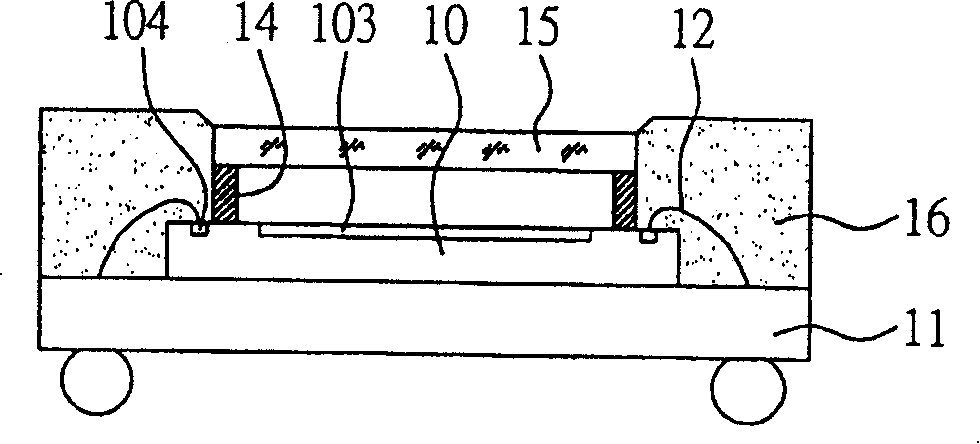

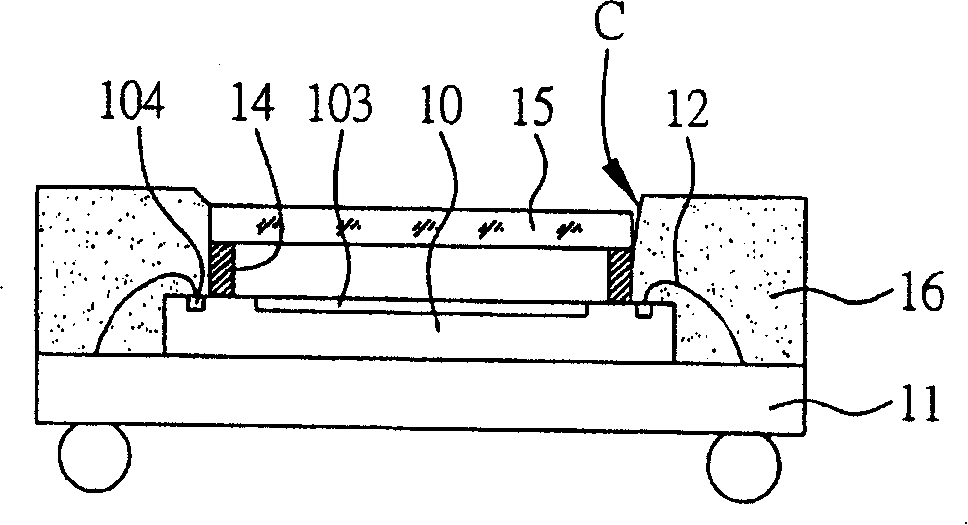

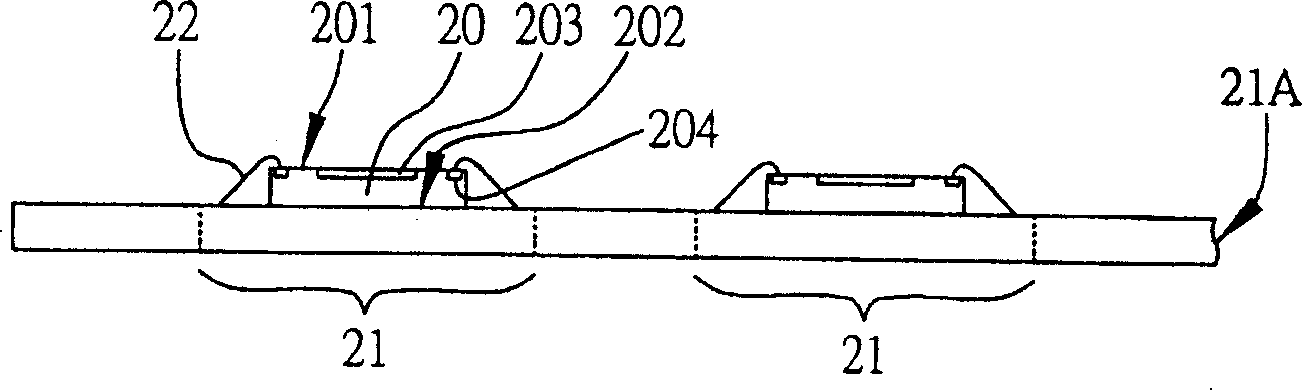

[0085] see Figure 2A to Figure 2D , is a schematic diagram of the sensing package and its manufacturing method of the present invention, and will be illustrated by mass-manufacturing the sensing package of the present invention in a batch manner.

[0086] Such as Figure 2A As shown, a module sheet 21A with a multi-chip carrier 21 is provided to mount the sensor chip 20 on the chip carrier 21 .

[0087] The sensing chip 20 has an active surface 201 and an opposite non-active surface 202, and the active surface 201 of the sensing chip 20 is provided with a sensing region 203 and an electrode pad 204, and the sensing chip 20 is based on its non-active surface. The active surface 202 is correspondingly placed on the chip carrier 21, and the electrode pads 204 of the sensing chip 20 and the chip carrier 21 are connected by bonding wires 22, so that the sensing chip 20 and the chip carrier 21 are electrically connected to each other. coupling. In addition, the sensing chip 20 c...

no. 2 example

[0093] see Figure 3A to Figure 3D , is a schematic diagram of the second embodiment of the sensing package and its manufacturing method of the present invention. This embodiment is roughly the same as the previous embodiment, the main difference is that in the previous embodiment, in order to allow the light-transmitting body to be connected to the sensing chip through the adhesive layer, a certain distance must be preset between the sensing area of the sensing chip and the electrode pad. The distance (generally greater than 300 μm) will relatively increase the size of the required sensing chip; and in this embodiment, the adhesive layer is mainly heated to make the adhesive layer appear in a molten state, and the bonding wire is directly connected to the end of the sensing chip. After the adhesive layer is cured, the light-transmitting body can cover and seal the sensing area, so as to save the pre-installed light-transmitting body between the sensing area of the sensing...

no. 3 example

[0104] see also Figure 4A and Figure 4B , is a schematic cross-sectional view of the third embodiment of the manufacturing method of the sensing package of the present invention. This embodiment is substantially the same as the previous embodiment, and only the main difference is shown for simplification of the drawings, that is, after the sensing chip 40 is placed and electrically connected on the module sheet 41A with the multi-chip carrier 41, the sensing chip 40 is then placed on the sensing chip 41A. The chip 40 is covered with a monolithic light-transmitting body 45A such as glass, wherein the peripheral dimension of the monolithic light-transmitting body 45A exceeds the cut-off line of the sensing package to be completed, and the monolithic light-transmitting body 45A A plurality of adhesive layers 34 are provided on the body 45A, and the position of the adhesive layer is corresponding to the sensing chip 40 connected to each of the chip carriers 41, and makes it cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com