Crystalline base of escitalopram and orodispersible tablets comprising escitalopram base

A technology of escitalopram and dispersible tablets, applied to the crystalline base of escitalopram: [0019] [, with melt agglomeration or melt coating filler, wherein the active pharmaceutical ingredient has 40-, It can solve the problems of fast disintegrating tablets, poor tablet strength, hindering the application of conventional packaging materials, and low friability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

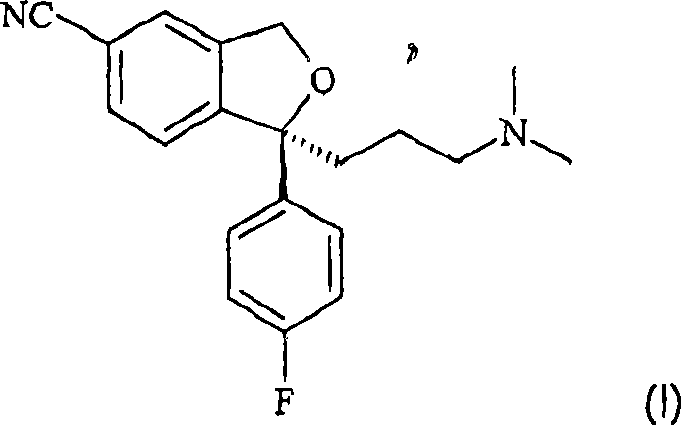

[0103] Embodiment 1, free release escitalopram free base from escitalopram oxalate

[0104] 704 g of escitalopram oxalate were placed in a 6 L three-necked flask equipped with a mechanical stirrer and a pressure compensating funnel. 3 L of water was added, followed by 600 mL of diethyl ether. The pH was adjusted to 9-9.5 by adding 27% w / w ammonia and the mixture was stirred for 1 / 2 hour. The phases were separated and the aqueous phase was re-extracted with 300 mL diethyl ether. The combined organic phases were washed twice with 300 mL of water and washed with MgSO 4 Drying, filtration and evaporation under vacuum at 40°C gave a light brown oil.

[0105] Yield: 542.5 g (98.4%)

Embodiment 2

[0106] Embodiment 2, the precipitation of escitalopram hydrobromide, the release of free base and the crystallization of base

[0107] Precipitation of escitalopram hydrobromide:

[0108] 3 kg of escitalopram free base (purified by HPLC: 99.16% (area %)) as a light brown oil dissolved in 12 kg of 2-propanol was added to 20 L with mechanical stirring, reflux condenser, scrubber , gas inlet and thermometer for thermostatic control of the reactor. The solution was heated to 40° C., and then HBr gas was injected into the solution until the pH was 3-4. The reaction is exothermic and the temperature in the reactor is maintained between 40-43°C. A small amount of seed crystals (escitalopram hydrobromide, 100-200 mg) was added and crystallization started within 10 minutes. The mixture was then cooled to 10° C. over 5 hours and kept at this temperature for a further 12 hours. The crystals were filtered off, rinsed on the filter with 3 x 1 L 2-propanol, and dried under vacuum at 60...

Embodiment 3

[0119] Embodiment 3, the crystallization of escitalopram free base

[0120] 520 escitalopram free base (purity: 99.25%; HPLC) of light brown oily state was placed in 2 L equipped with mechanical stirrer, reflux condenser, N 2 Inlet / outlet and thermometer for thermostatic control of the reactor. 50 mL of ethyl acetate was added, and the mixture was heated to 35° C., followed by the addition of 1.3 L of heptane. When the solution was homogeneous, slow cooling to -5°C was initiated over 12 hours. When the temperature was 20°C, a small amount of seed crystals (escitalopram base) (10-20 mg) was added. Crystallization begins at about 10°C. The mixture was stirred at -5°C for another 5-7 hours, then the crystals were filtered off by filtration. The crystals were rinsed with 2 x 150 mL heptane on the filter and dried to constant weight under vacuum at 25°C.

[0121] Yield: 485 g (93.3%)

[0122] HPLC purity of product: 99.58% (area %)

[0123] Melting point (DSC, onset): 45.8°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com