Surface protective film

A surface protection film and rubber technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve problems such as insufficient performance, poor adhesion stability over time, and difficulty in peeling off attached objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

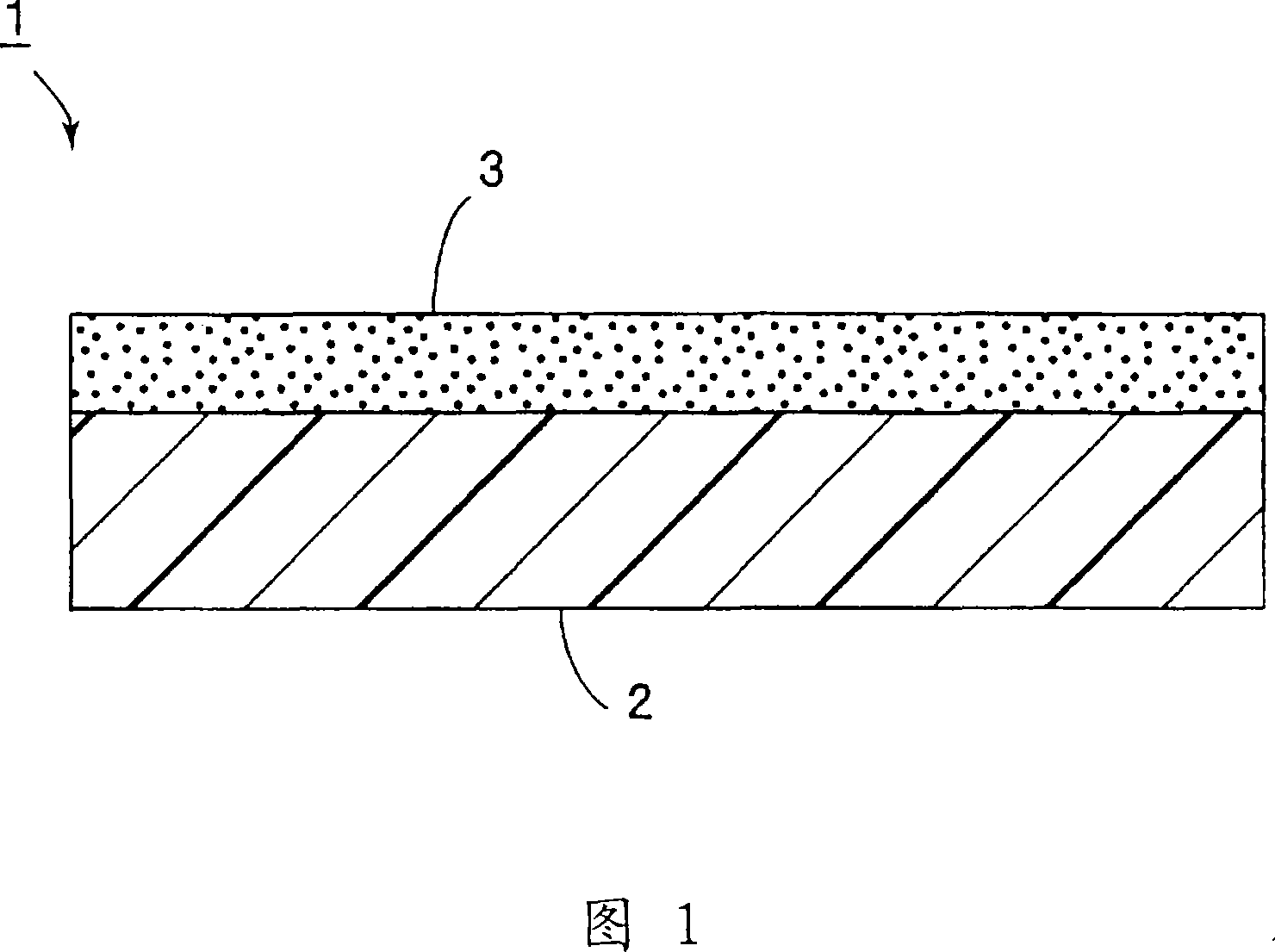

[0135] An adhesive composed of 100 parts by weight of styrene-based elastomer SIBS (2) and 20 parts by weight of alicyclic-based saturated petroleum resin (manufactured by Arakawa Chemical Co., Ltd., trade name: AlconP125) as tackifier resin was combined through a T-die Co-extrusion with a polypropylene base material layer made of polypropylene (produced by Sunallomer, model: PB170A) to obtain surface protection with a 10 μm thick rubber-based adhesive layer laminated on a 50 μm thick polypropylene base material membrane.

Embodiment 2~5 and comparative example 1~6

[0137] A surface protective film was obtained in the same manner as in Example 1, except that the styrene-based elastomer and tackifier resin used and their mixing ratios were changed as shown in Table 1 below.

[0138] (Evaluation of Examples and Comparative Examples)

[0139] The (1) shear storage elastic modulus and (2) tensile storage elastic modulus of the rubber-based pressure-sensitive adhesive layer in each of the surface protective films obtained as described above were determined according to the following points. In addition, (3) initial adhesion force, (4) initial peeling force, (5) lasting adhesion force, and (6) contamination by adhesion of the obtained surface protection film were evaluated according to the following points. The results are shown in Table 1 below.

[0140] (1) Shear storage modulus

[0141]Using a dynamic viscoelasticity spectrometer (manufactured by IT Instruments Co., Ltd., model: DVA200), the shear of the rubber-based adhesive layer was mea...

Embodiment 6

[0158] 70 parts by weight of SIBS (2) produced by Kaneka Co., Ltd. as a block copolymer (D) and 30 parts by weight of SEBS (2) produced by Asahi Kasei Co., Ltd. as a block copolymer (F) were mixed, and added as a tackifier 20 parts by weight of the resin was produced by YASUHARA CHEMICAL under the trade name ClearonLH to obtain an adhesive.

[0159] In addition, the above-mentioned SIBS as the block copolymer (D) is a block copolymer of styrene, isobutylene, and styrene, and includes a styrene-based polymer block (A) and an isobutylene-based polymer block (C). The above-mentioned SEBS as the block copolymer (F) is a block copolymer of styrene with ethylene, butene and styrene, including hydrogenation of a styrene-based polymer block (A) and a butadiene polymer block item (E).

[0160] Next, a rubber-based adhesive layer made of the adhesive and a base material layer made of polypropylene were co-extruded by a T-die method to obtain a 10-μm-thick rubber-based base material lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com