Method for preparing low caffeinum green tea

A low-caffeine, green tea technology, applied in tea processing before extraction, etc., can solve the problems of complicated process, high processing cost, expensive processing equipment, etc., and achieve the effect of ensuring food safety, convenient operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of described low caffeine green tea comprises the steps:

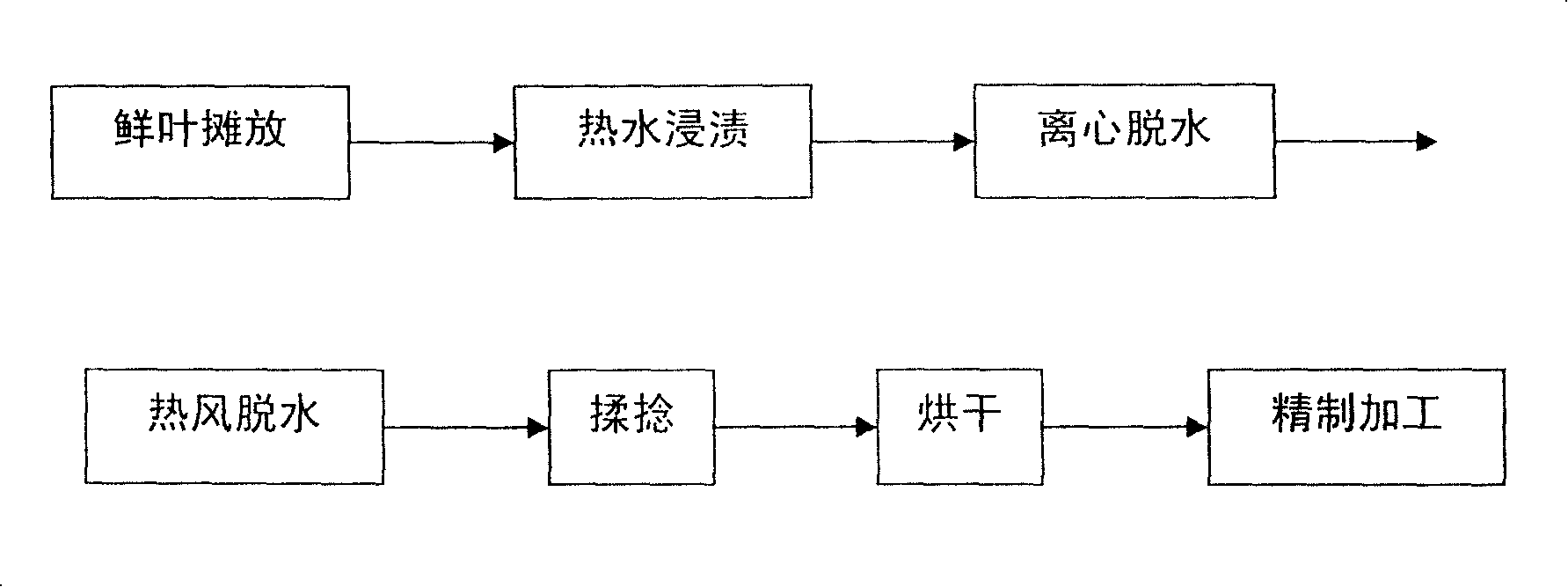

[0020] Spreading of fresh leaves, soaking in hot water, centrifugal dehydration, hot air dehydration, rolling, drying, and refined processing, the technological requirements of each step are as follows:

[0021] ① Fresh leaves are spread to cool: the spread thickness is 2 to 3 cm, and the spread time is 4 hours;

[0022] ②Hot water dipping: soak the fresh leaves of the tea leaves after being cooled with hot water at 95°C to 96°C, and the weight ratio of fresh leaves to hot water is 1:3; the dipping time is controlled at 150 seconds; cool down after dipping The leaf temperature should be controlled at 20°C to 25°C;

[0023] ③Dehydration: Centrifugal dehydration is adopted, the water content of the tea leaves is controlled at 70% to 72%, the centrifugal dehydration time is 120 seconds, and the dehydration speed is 3000 rpm;

[0024] ④Hot air dehydration: the temperature of hot air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com