Hetian jade imitation ceramic tile and preparation method thereof

A manufacturing method and ceramic tile technology, which are applied in imitation Hetian jade tiles and its manufacturing field, can solve the problems of polished tiles such as unsatisfactory gloss, high radiation, and inferior decorative effect to natural stone, and achieve easy cleaning and maintenance, and good antifouling , high gloss and anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

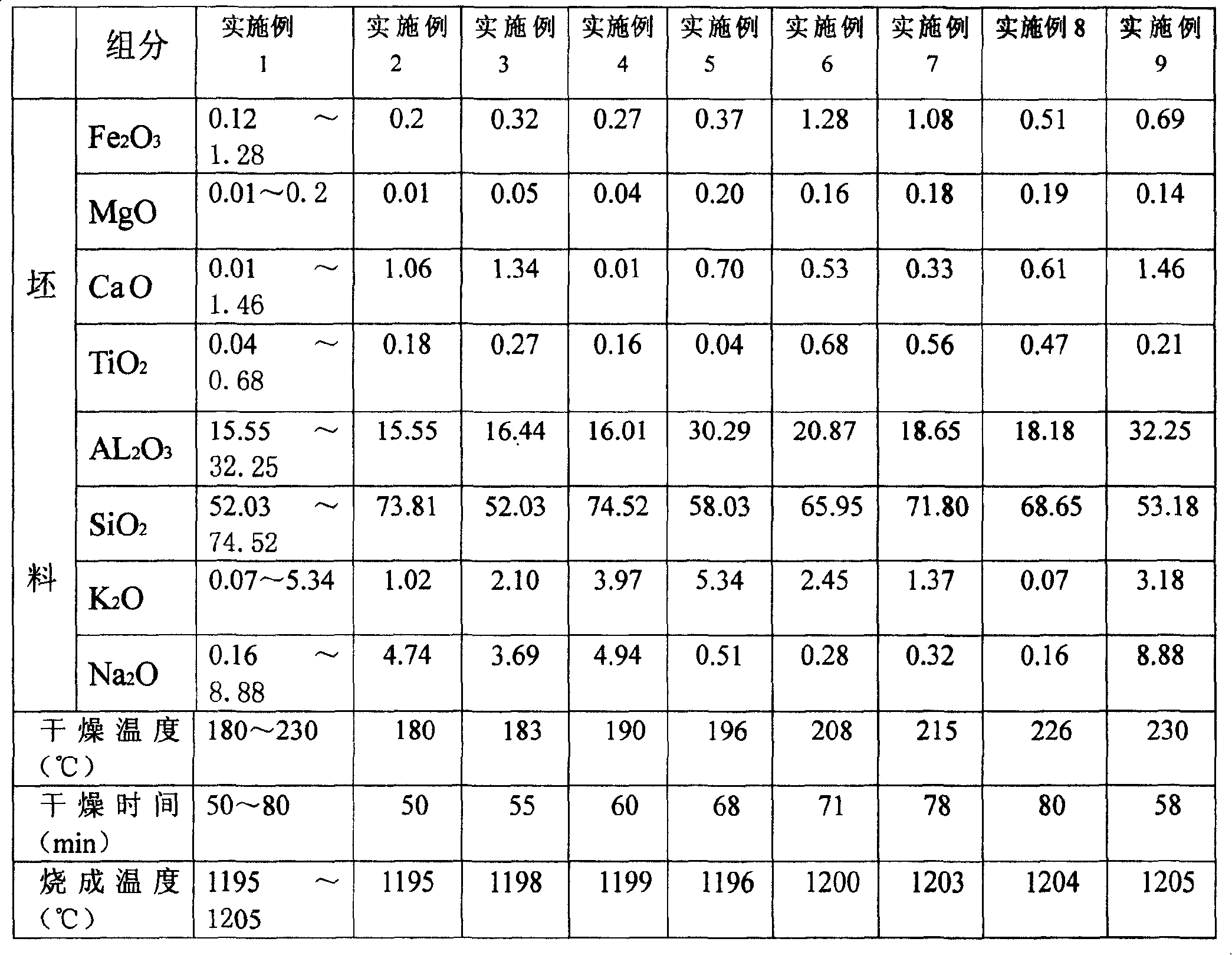

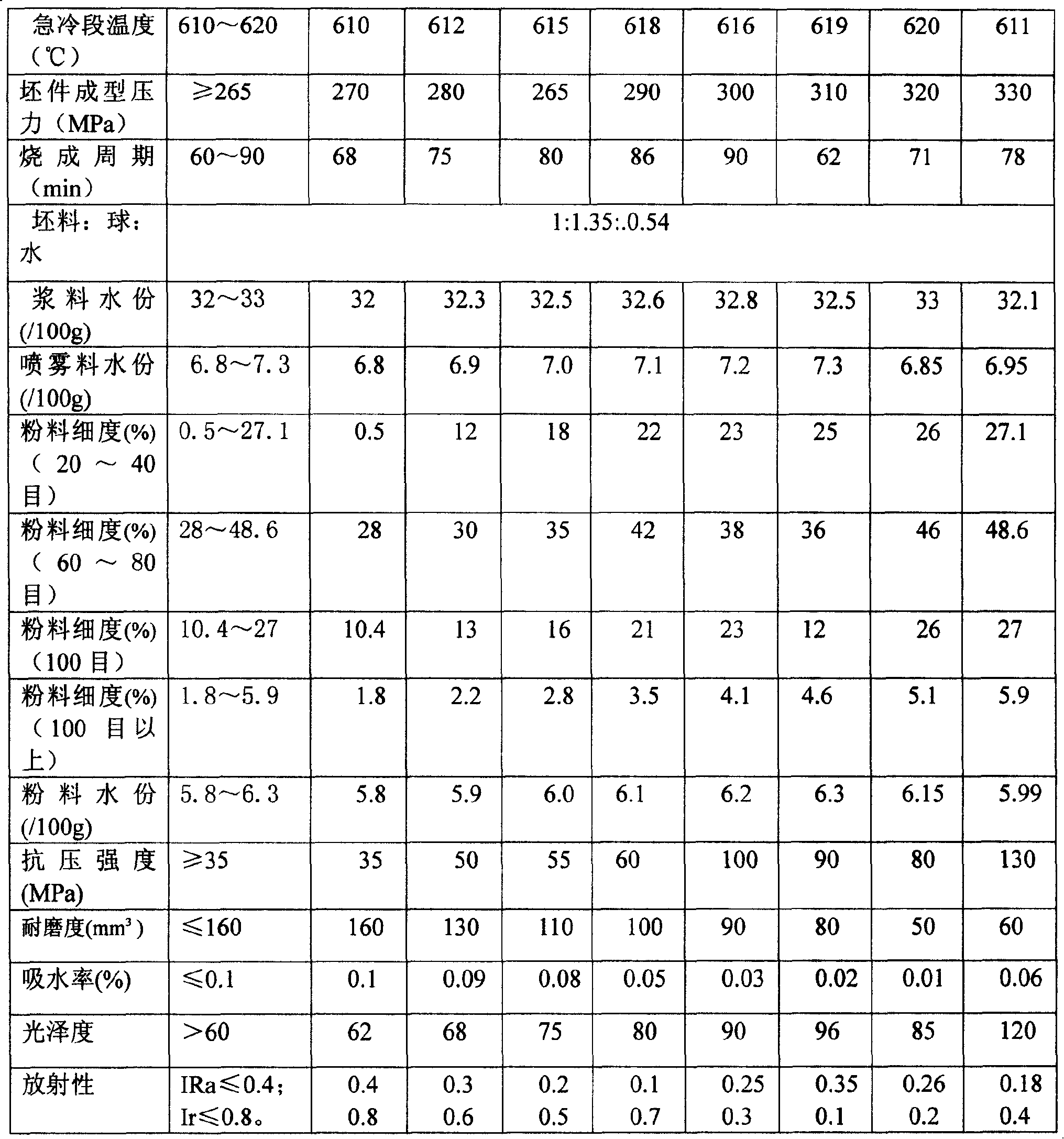

[0026] The present invention will be described in further detail below in conjunction with specific embodiment (billet unit is weight percent):

[0027] surface

[0028]

[0029] Continuation

[0030]

[0031] Purchasing→Formula formulation→Batching according to the above-mentioned examples→Ball milling→Slurry→Sieving stale, iron removal→Spray drying→Powder→Stay homogenization→Rows of bricks→Drying→Printing→Firing (surface temperature and bottom temperature are compared at the same time Ordinary micro-powder bricks are lowered by 5-10°C, and the quenching section is controlled between 610-620°C)→polishing→grading→packaging→storage.

[0032] In the fabric of brick adobe, the present invention mixes 90-97% translucent Yulinglong micropowder with different color-developing base powders and makes random fabrics; it consists of translucent Yulinglong micropowder, translucent particles and various colors The micro-powder blank is designed according to the predetermined fabri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap