Layer sequence and method of manufacturing a layer sequence

A layer sequence, nickel layer technology, applied in the field of manufacturing layer sequence, can solve the problems of time-consuming and expensive, and achieve the effect of simplifying the manufacturing process, reducing the total cost and making the production simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The illustrations in the figures are schematic. In different figures, similar or identical elements are provided with the same reference signs.

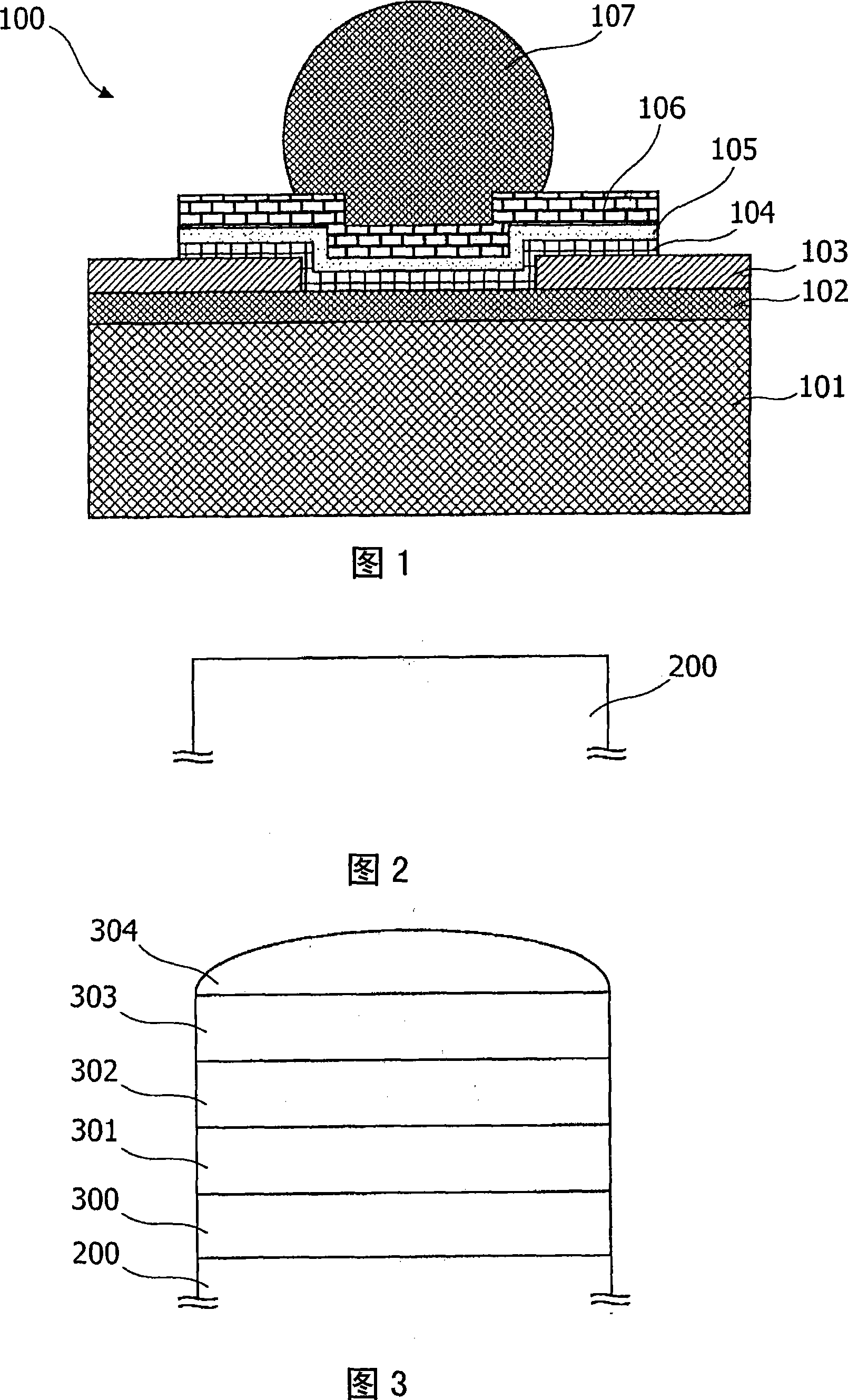

[0060] Hereinafter, referring to FIG. 1 , the layer sequence 100 will be described.

[0061] The layer sequence 100 comprises a semiconductor chip component 101 on which an interconnect metal layer 102 is applied. A passivation layer 103 is deposited and patterned on the interconnect metal layer 102 . Also, an aluminum layer 104 is deposited on the interconnection metal layer 102 and the passivation layer 103 . Further, a nickel / vanadium layer 105 is deposited on the aluminum layer 104 . Also, a copper layer 106 is deposited on the nickel / vanadium layer 105 . Then, lead-containing or lead-free solder balls 107 are applied on the copper layer 106 .

[0062] Referring to FIG. 1 , UBM (Under Bump Metallization) is used as an interconnection layer for preformed solder balls. A metallization stack is created from Al / NiV / Cu (l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com