Self-propelled combined accuracy work machine for ploughing, smoothing, seeding and maintaining

A self-propelled and walking device technology, which is applied to crop processors, harvesters, agricultural machinery, etc., can solve the problems of not being able to guarantee higher seedling emergence rate, strong seedling rate, more mechanical output times, and high production input costs. Achieve the effect of reducing the number of land entry and energy consumption and agricultural production input, the number of land entry is large, and the power utilization rate is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

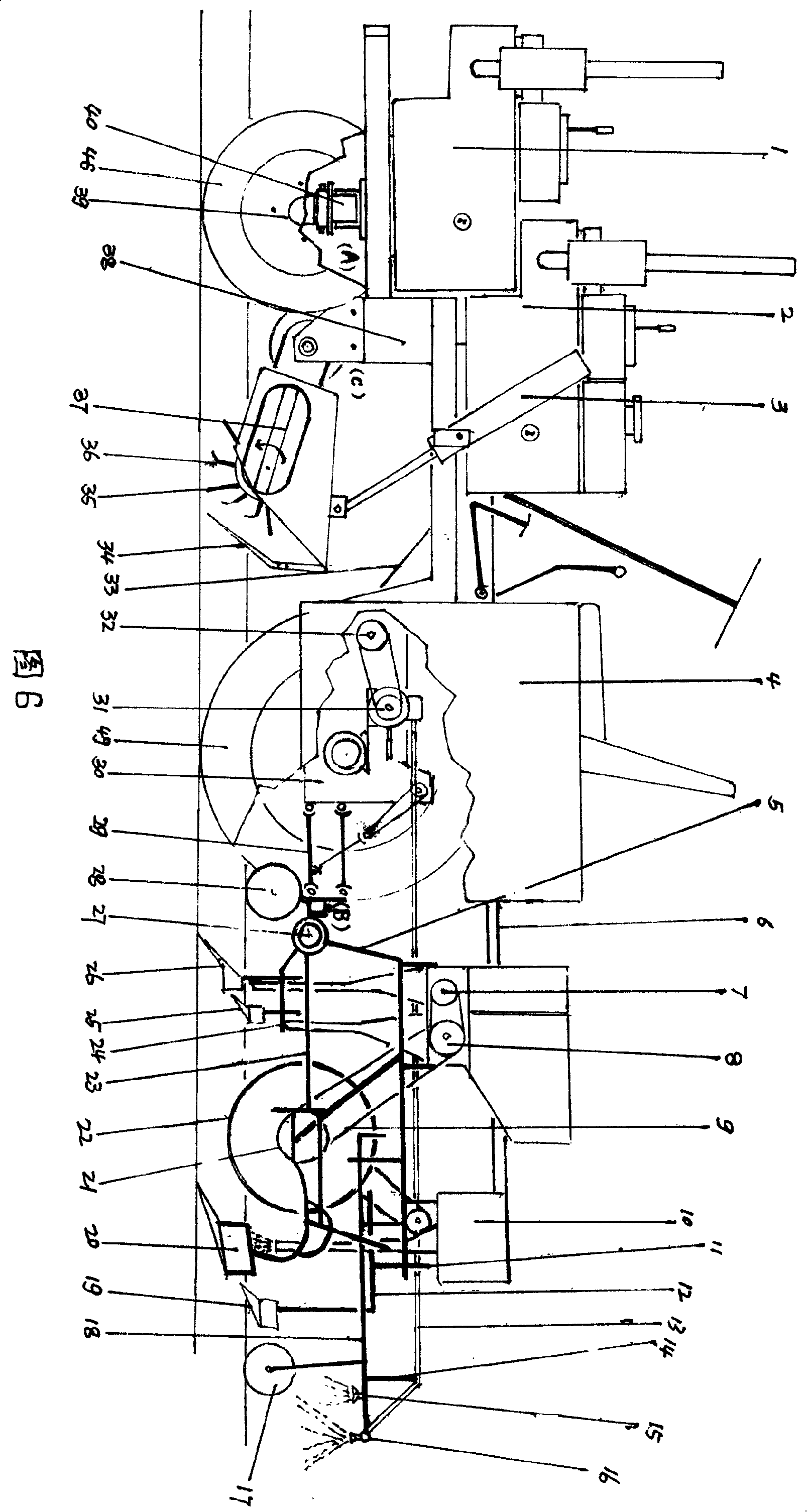

[0013] As shown in Figure 6: by direction wheel (46), front axle (39), front suspension (40), beam frame (38), rear axle (30), drive wheel (49), power machine (2), power machine ( 1) combined into a traction device, and the front axle (39) is connected at the beam frame (38) A place by the front suspension (40). The tiller (37) is installed under the beam frame (38) in the middle of the direction wheel (46), the drive wheel (49) and connected with the C place again. Install the pressure pump (31) on the left side of the rear axle (30). Fertilization ditch opener (26), sowing ditch opener (25) are installed on the suspension tie rod (27) by ditch opener frame (24) again. The ridge cover (20) is sleeved on the suspension tie rod (27) by the ridge cover pull rod (23). Deep fertilizer applicator (7) seeder (8), pressure seed wheel (22), water injector (10) are successively installed on the sowing and fertilizing frame (5), and are sleeved on the suspension tie rod (27). The soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com