Environment friendly system for smelting copper and copper alloy

A copper alloy and environmentally friendly technology, applied in the field of copper processing, can solve the problems of polluting the environment, not being able to reuse, and dust not being able to be recycled, and achieve the effect of improving the working environment

Active Publication Date: 2008-06-11

JINTIAN COPPER GROUP CORP NINGBO +1

View PDF0 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0020] Adopting an environmental protection system for smelting copper and copper alloys of the present invention, smelting brass HPb59-1 with waste miscellaneous copper, the environment of the smelting workshop is greatly improved, and the particles in the exhausted smoke and dust reach 25mg / m 3 , the dust is recycled.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

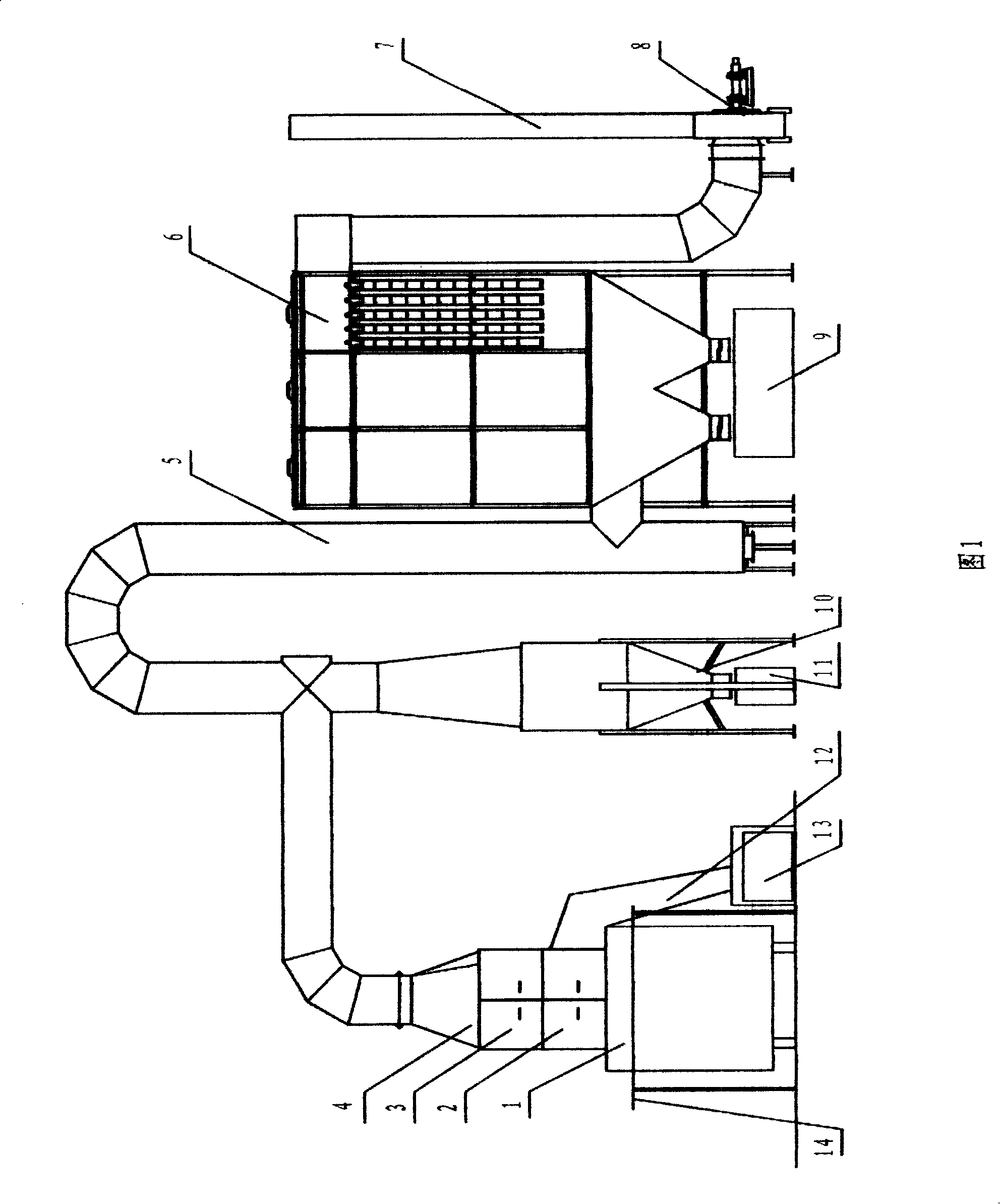

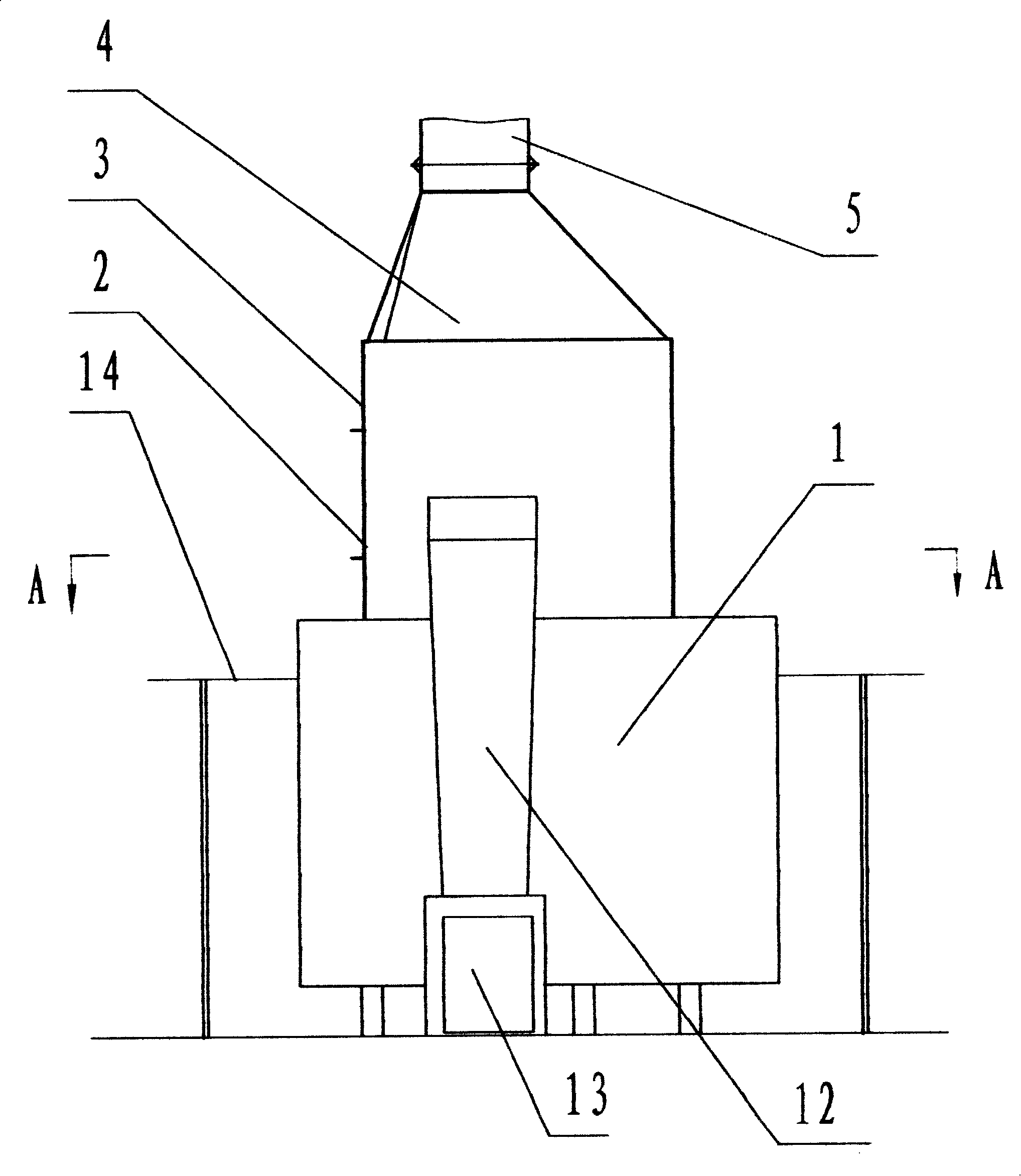

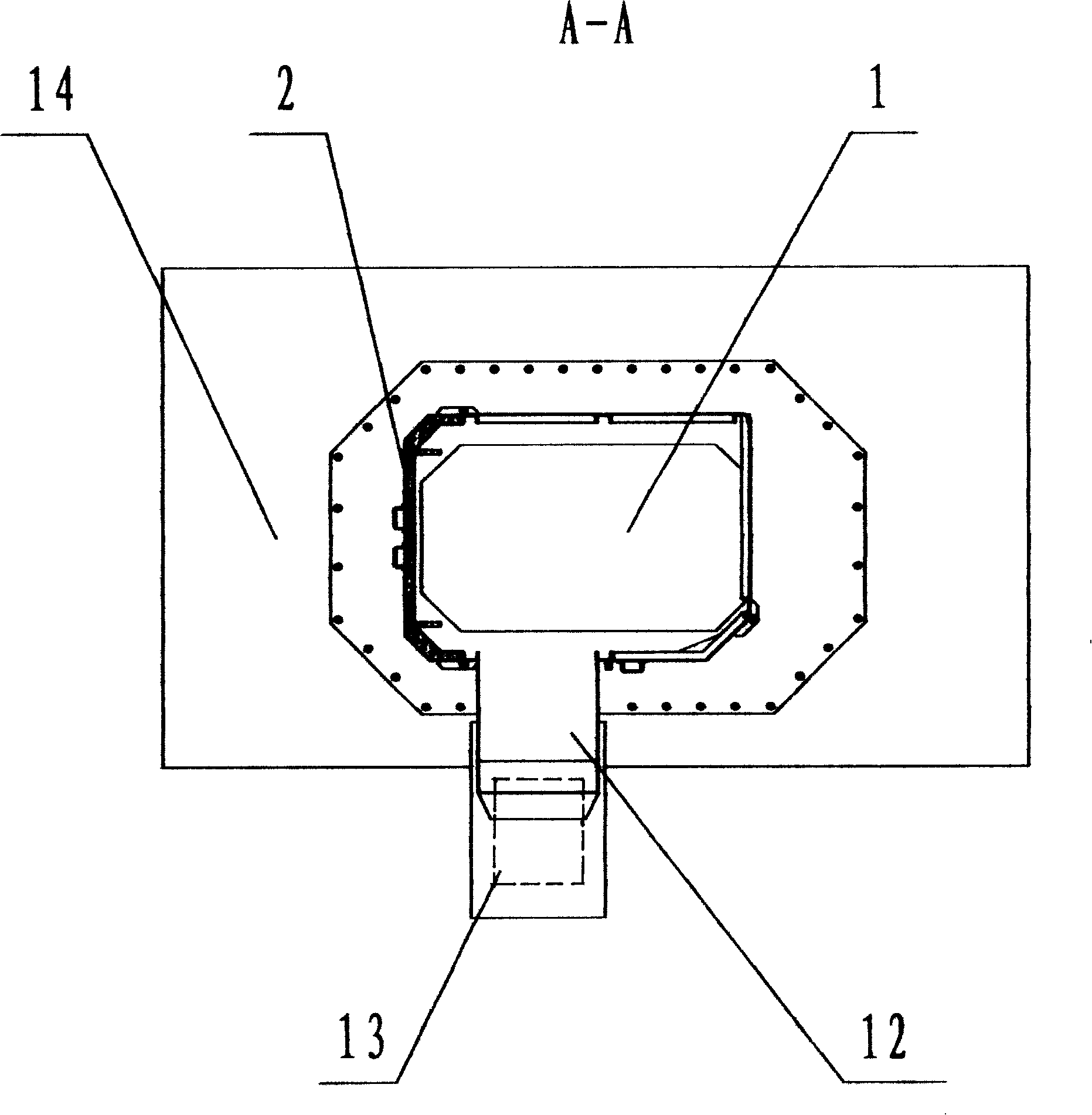

The invention belongs to the copper alloy processing field. Aiming at that a larger space is provided between a smelting furnace and a dust cover separated with each other in the prior art, when using partial scrap copper and even the entire scrap copper to smelt copper or copper alloy, the pollution is serious and the useful materials in the dust are wasted, an environmental protection system of copper and copper alloy smelting of the invention is adopted. The useful materials in the dust are recovered, the working environment of smelting is greatly improved and the waste gas exhausted by smelting is superior to the current national industrial waste gas emission standard. The system consists of a smelting furnace (1), a lower gate of the dust cover (2), an upper gate of the dust cover (3), a dust cover (4), a dust collector cyclone (10), a powder collecting box (11), a pipeline (5), a pulsed jet cloth filter (6), a dust box (9), an induced draft fan (8), a vent pipe (7), a slag drop channel (12), a slag connecting box (13) and an operations area (14). The system is also suitable for the environmental protection systems of other nonferrous metal and ferrous metal smelting.

Description

technical field [0001] An environmental protection system for smelting copper and copper alloys belongs to the field of copper material processing. Background technique [0002] In the existing copper and copper alloy melting and casting technology, the general smelting furnace is a tilting furnace with a rotatable shaft, and the smelted alloy melt is poured into a tundish or a holding furnace for further processing. Therefore, the fume hood above the smelting is generally separated from the smelting furnace, and there is a large space between the two to facilitate workers' operations, such as adding alloy material, adding covering agent, adding scouring agent, scooping slag, pouring alloy melt, etc. . Therefore, in the actual production process, especially when the raw materials contain some scrap copper or all of it is scrap copper, because the scrap copper is accompanied by a large amount of other low-melting point metals, inorganic non-metallic compounds, organic substa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F27D17/00B01D50/00

Inventor 张学士张建华叶国海朱云福刘新才

Owner JINTIAN COPPER GROUP CORP NINGBO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com