Low threshold voltage electrostatic micro-relay

A low-threshold voltage, micro-relay technology, applied in electrostatic relays/electro-adhesion relays, relays, circuits, etc., can solve problems such as reducing driving voltage and compatibility, reducing contact resistance, simple manufacturing process, and increasing contacts. Effect of load current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

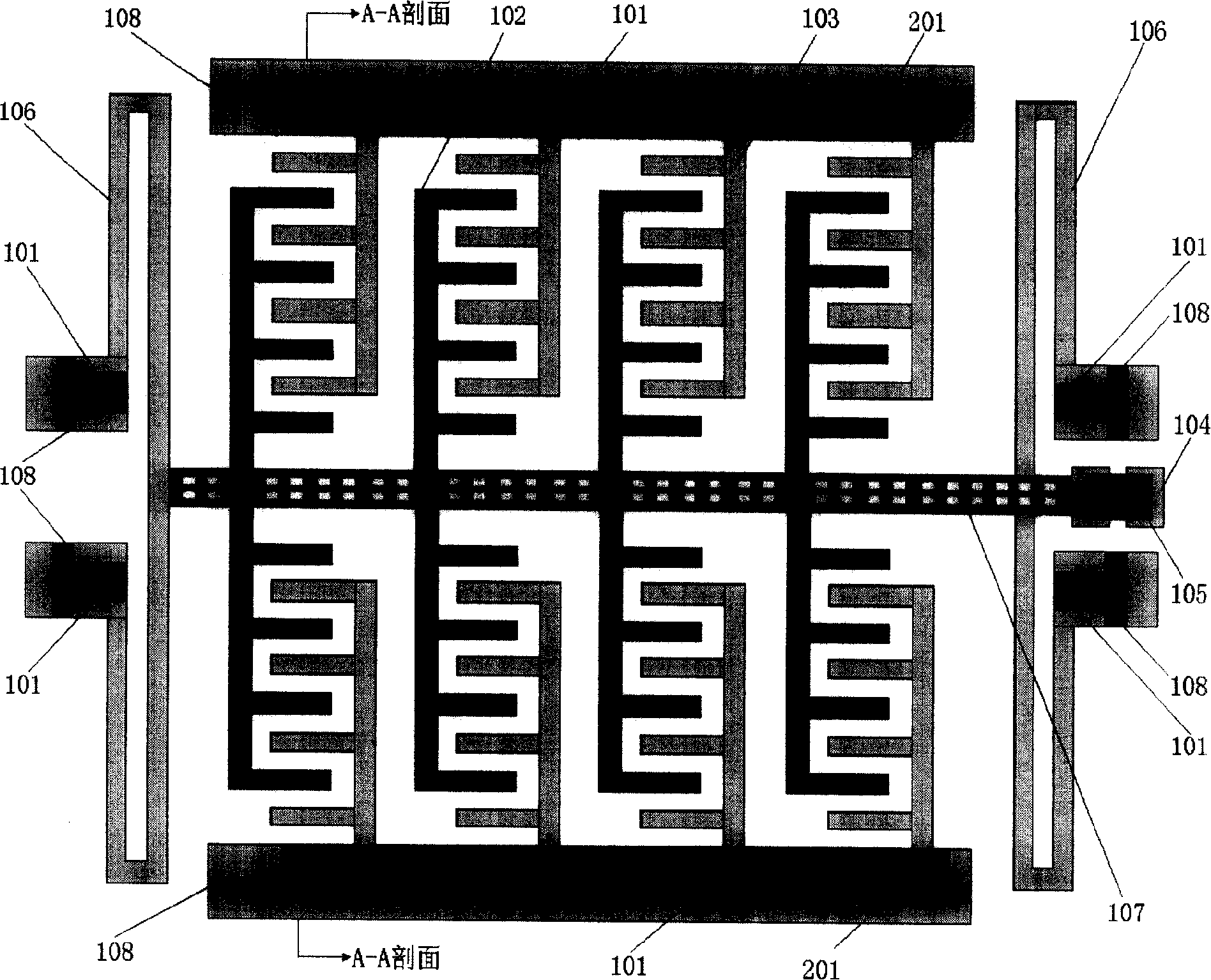

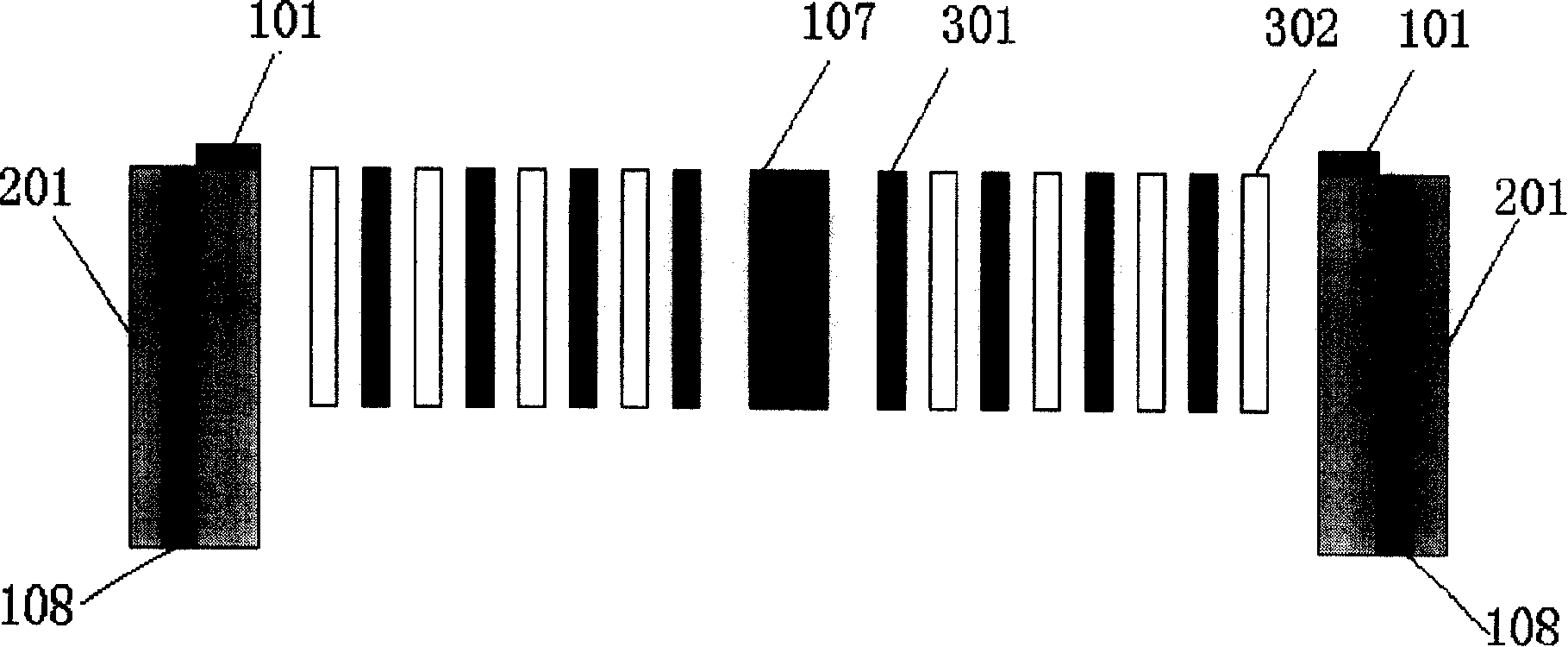

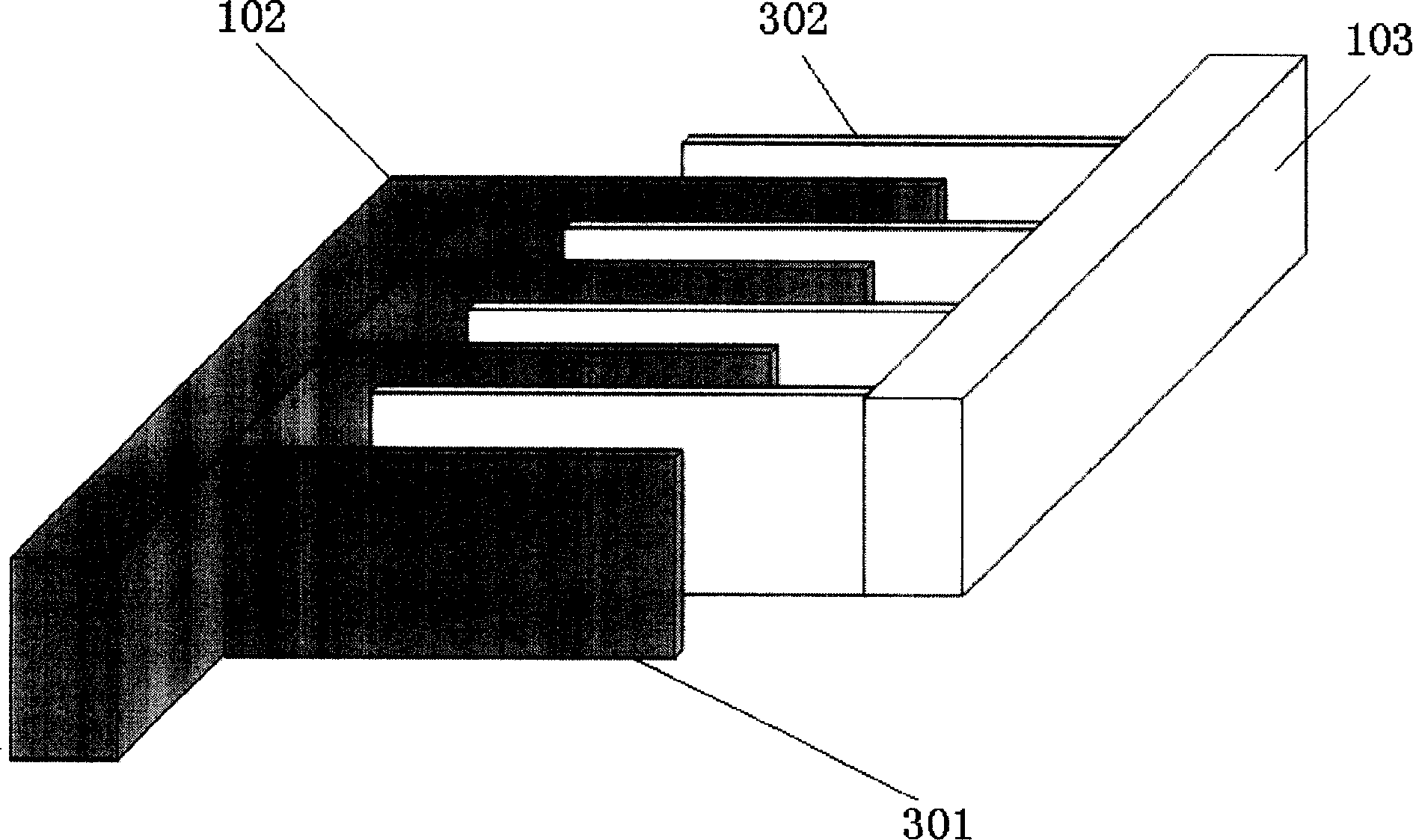

[0022] The low-threshold voltage electrostatic micro-relay includes a welding block 101, a movable comb 102 and a fixed comb 103, a contact 104, an isolation barrier 105, a folded spring beam 106, a multi-stage comb connecting beam 107, a partition wall 108, a lining The bottom 201, wherein, the welding block 101 is used to apply electric excitation; two or more movable comb teeth 102 are connected in parallel, and more than two fixed comb teeth 103 are connected in parallel, and the number of movable comb teeth and fixed comb teeth are equal and arranged at intervals to form Cascaded comb structure, the movable comb has more than two forks 301, the fixed comb has more than two forks 302, and the corresponding movable comb has two forks 301 and the fixed comb has two forks. The teeth 302 are equal in number and arranged at intervals in a staggered shape, forming plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com