Excimer light irradiation apparatus

A light irradiation device and excimer technology, applied in irradiation devices, optics, nonlinear optics, etc., can solve the problems of large amount of inert gas, uneven oxygen concentration, and high manufacturing cost, and reduce the amount of gas used and the processing cost. The effect of increasing the speed and stabilizing the oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

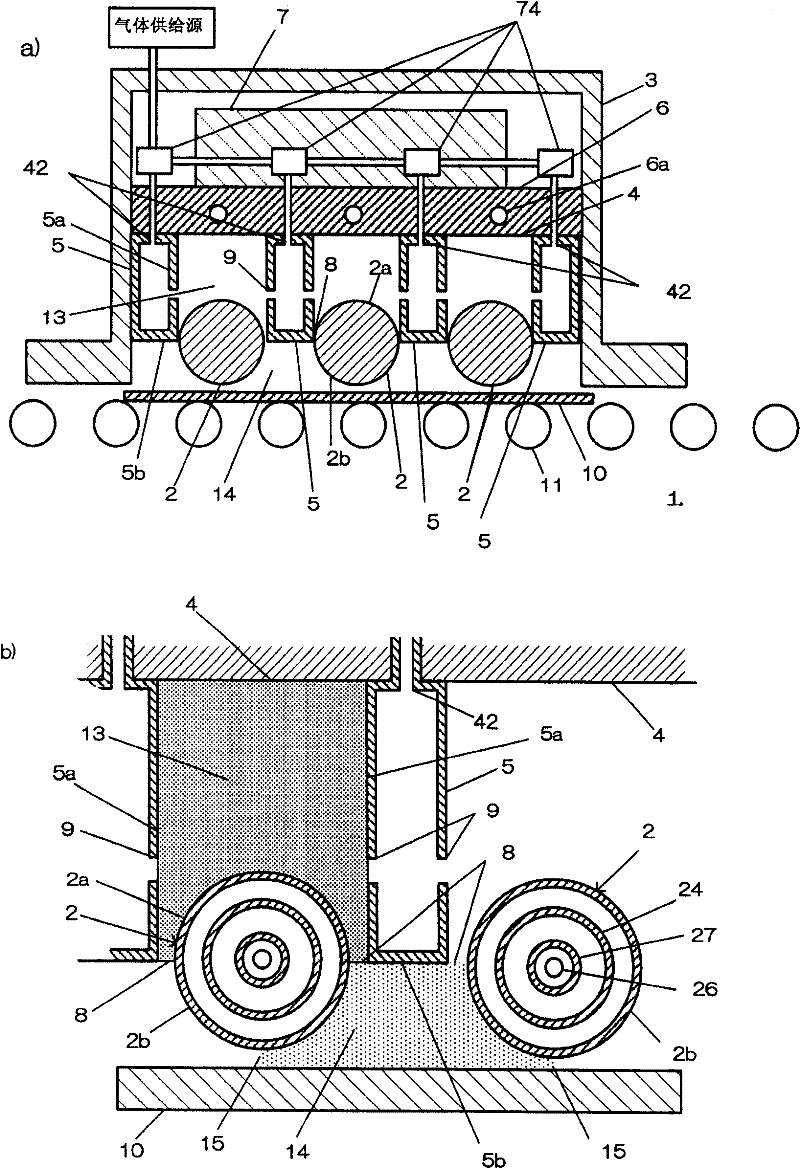

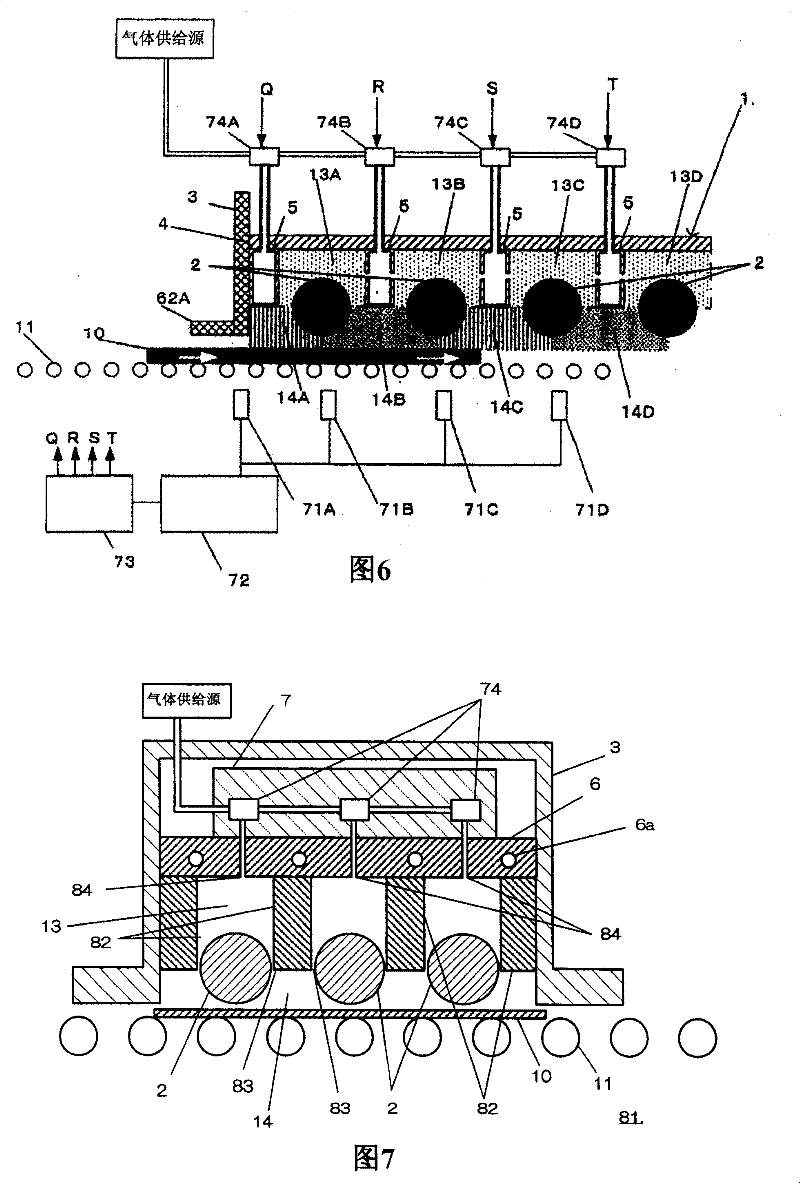

[0040] As a first example, figure 1 shows the excimer photoirradiation device of the present invention. figure 1 - a) is a schematic cross-sectional view of the excimer light irradiation device 1 cut along a plane perpendicular to the tube axis direction of a plurality of approximately rod-shaped excimer lamps 2 arranged in parallel. In this excimer light irradiation device 1 , a plurality of excimer lamps 2 are arranged side by side in a lamp housing 3 . Inside the lamp housing 3, a plurality of excimer lamps 2 are arranged in parallel. A partition wall 4 is provided inside the lamp housing 3, and a plurality of jet tubes 5 for jetting gas including nitrogen and other inert gases are arranged in parallel on the partition wall 4, and the excimer lamp 2 is arranged between the jet tubes. In addition, each jet tube 5 is arranged in the lamp housing 3 so that a narrow portion 8 is formed between the excimer lamp 2 and each jet tube 5 . A cooling block 6 is provided above the...

no. 2 example

[0052] Figure 4 It is a cross-sectional view showing the shape of another gas injection pipe as the second embodiment of the present invention. Figure 4 In the gas injection pipe 51 shown in -a), the shape of the ejection port provided for ejecting gas starts from the longitudinal end of the air ejection pipe 51 in the order of the ejection ports 9a, 9b, 9c, and 9d, and the aperture diameter decreases. Small. By adopting such a structure, the flow rate of the gas jetted from the gas jet tube 51 is different in the longitudinal direction of the gas jet tube 51, and the flow rate of the gas jetted near the end portion of the gas jet tube 51 is larger than that near the center of the gas jet tube 51. . By assembling the jet tube 51 into the excimer light irradiation device of the present invention, compared with the vicinity of the center of the excimer lamp tube axial direction of the lamp housing of the excimer light irradiation device, the gas flow can be made to the vicin...

no. 3 example

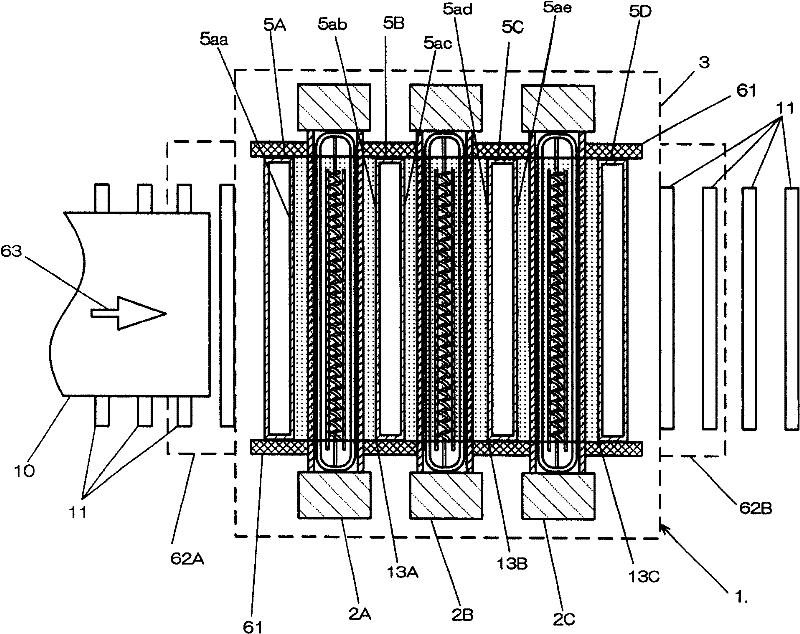

[0055] Figure 5 A third embodiment of the present invention is shown. In the third embodiment, a case is shown in which the flow rate of gas flowing into the first replacement space is different in each first replacement space formed corresponding to each excimer lamp. Figure 5 The illustrated excimer light irradiation device 1 is a view of the inside of the lamp housing of the excimer light irradiation device 1 in which three excimer lamps 2A, 2B, and 2C are arranged in parallel are viewed from above the device. Also, a conveyance path formed by arranging a plurality of roller belts 11 outside the excimer photoirradiation apparatus 1 and a state in which the substrate 10 is conveyed in the direction of the arrow 63 on the conveyance path are shown. The substrate 10 is carried in from the carrying port 62A of the excimer photoirradiation apparatus 1 and carried out from the carrying port 62B. Excimer lamps 2A, 2B, and 2C are arranged side by side between the transfer port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com