Method for preparing radiotolerant thermoplastic elastomer

A thermoplastic elastomer, radiation-resistant technology, applied in the field of preparation of functional polymer materials, can solve the problems of limited service life and application range, low dose tolerance, etc., achieve excellent melt flow properties, improve processing properties, and reduce fractures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

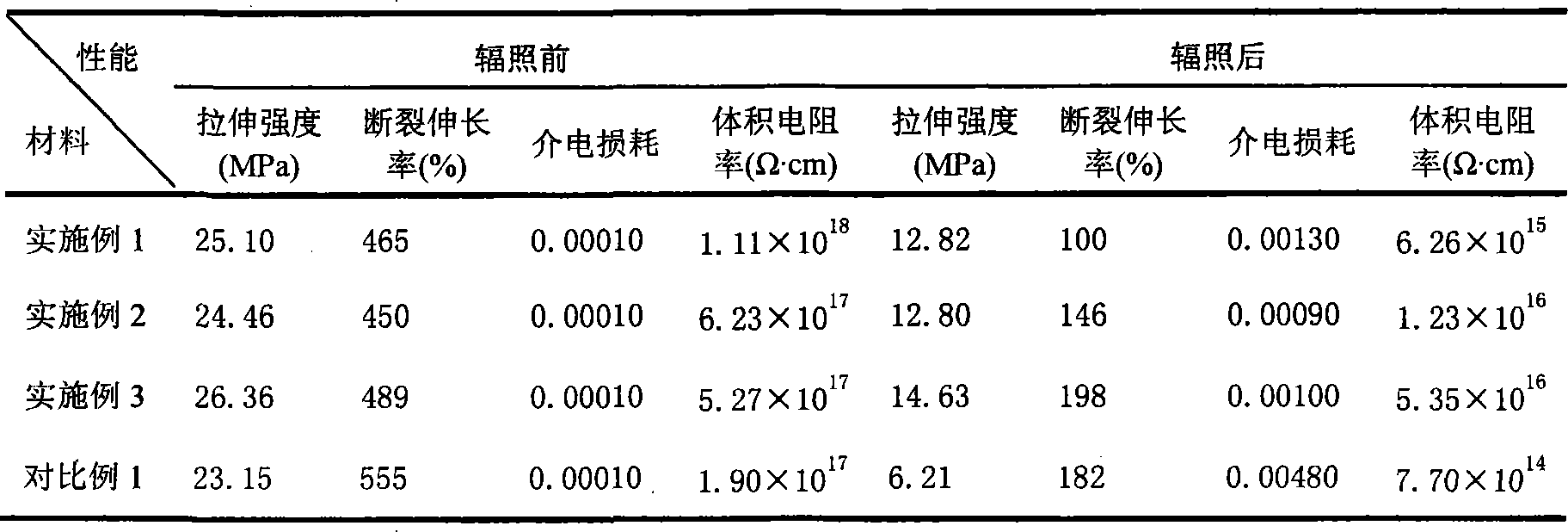

Examples

Embodiment 1

[0017] 84 grams of thermoplastic elastomers, 56 grams of polystyrene, 2.8 grams of anthracene and 0.4 grams of antioxidant 1010 were mixed in a Hack torque rheometer, the mixing temperature was 180 ° C, and the mixing time was 10 minutes. A radiation-resistant thermoplastic elastomer is obtained.

Embodiment 2

[0019] 84 grams of thermoplastic elastomers, 56 grams of polystyrene, 2.8 grams of pyrene and 0.4 grams of antioxidant 1010 were mixed in a Hack torque rheometer, the mixing temperature was 180 ° C, and the mixing time was 10 minutes. A radiation-resistant thermoplastic elastomer is obtained.

Embodiment 3

[0021] 84 grams of thermoplastic elastomers, 56 grams of polystyrene, 5.6 grams of pyrene and 0.4 grams of antioxidant 1010 were mixed in a Hack torque rheometer, the mixing temperature was 180 ° C, and the mixing time was 10 minutes. A radiation-resistant thermoplastic elastomer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com