Method for highly effective production and separating purification of Chinese caterpillar fungus extracellular polysaccharide

A high-efficiency technology for exopolysaccharides, applied in the field of rapid separation and purification of exopolysaccharides, can solve the problems of destroying polysaccharide structures, increasing industrial production costs, and destroying biological activities, achieving high purity and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

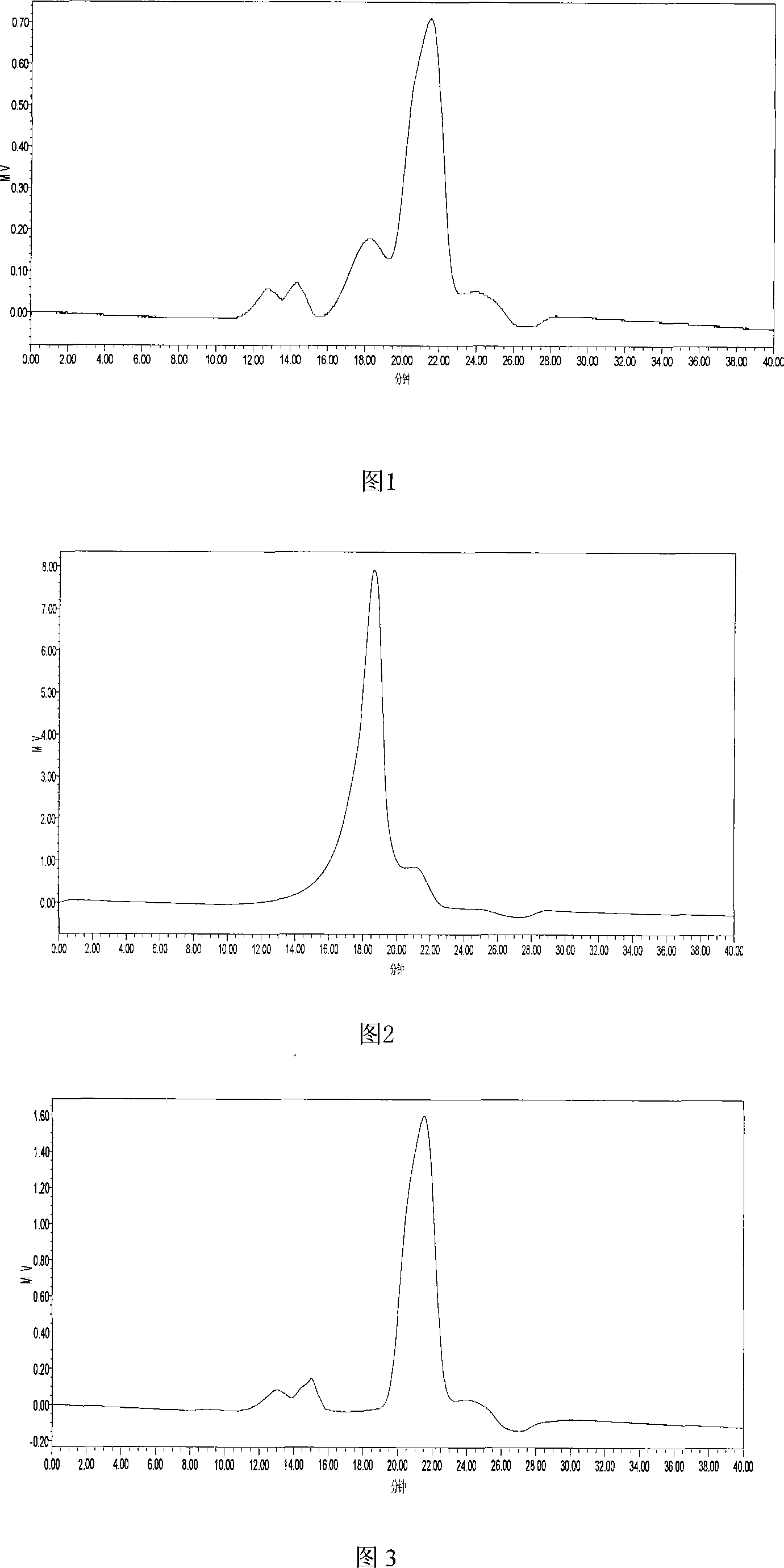

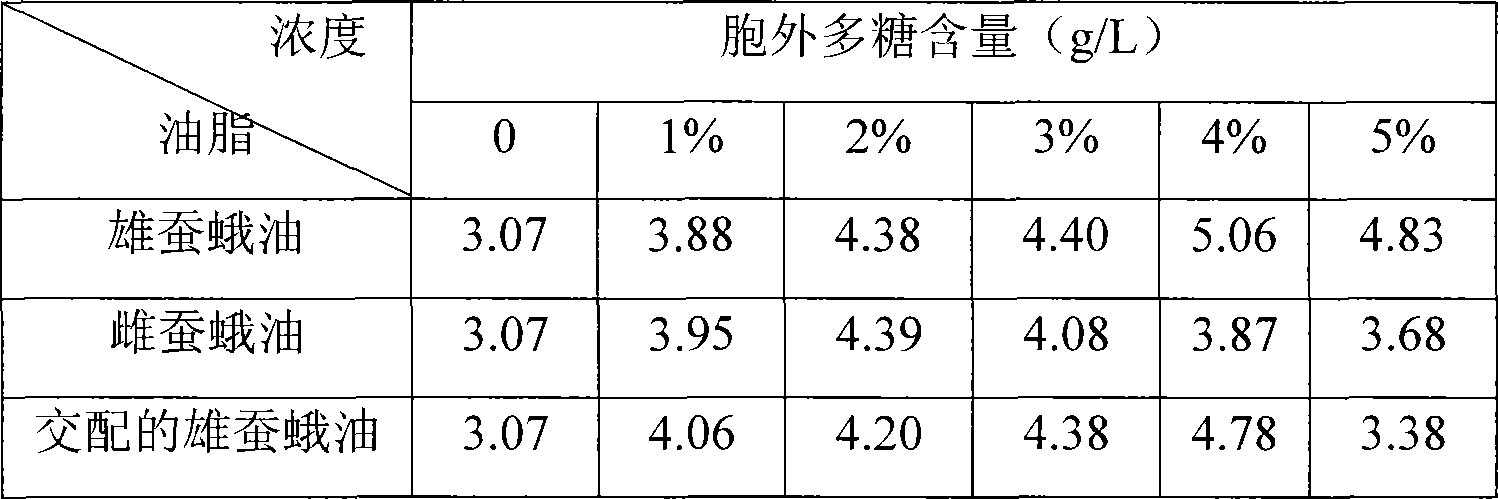

[0021] In a 5-liter culture bottle, inoculate Cordyceps militaris, the inoculation amount is 10%, the amount of the culture medium is: 3 liters, according to the culture medium, yeast extract powder 1.5%, brown sugar 2.5%, male silkworm moth oil 5%, KNO 3 0.95%, MgSO 4 0.2%, KH 2 PO 4 0.2% formula, static culture for 8 days. The obtained culture solution is filtered with ordinary filter paper, the filtrate is centrifuged at 12000rmp / min, and the filtrate is filtered with a 0.22 μm filter membrane, and the filtrate is continuously filtered with an ultrafiltration membrane with a molecular weight of 0.5 million Daltons, and the molecular weight cut-off value is 1, 5. 1. Different ultrafiltration membranes of 100,000 Daltons are used to concentrate the obtained filtrate by graded high-pressure ultrafiltration, and vacuum freeze-dry the obtained intercepted concentrated solution to obtain a single component with uniform molecular weight distribution and purity ≥ 95%.

Embodiment 2

[0023] In a 50 liter fermenter, inoculate Cordyceps militaris, the inoculum amount is 6%, the amount of the fermenter medium is: 30 liters, according to the medium yeast extract powder 0.8%, brown sugar 1.5%, male silkworm moth oil 4%, KNO 3 0.85%, MgSO 4 0.1%, KH 2 PO 4 0.1% formula, static culture for 6 days. The obtained culture solution is filtered with ordinary filter paper, the filtrate is centrifuged at 12000rmp / min, and the filtrate is filtered with a 0.22 μm filter membrane, and the filtrate is continuously filtered with an ultrafiltration membrane with a molecular weight of 0.5 million Daltons, and the molecular weight cut-off value is 1, 5. 1. Different ultrafiltration membranes of 100,000 Daltons are used to concentrate the obtained filtrate by graded high-pressure ultrafiltration, and vacuum freeze-dry the obtained intercepted concentrated solution to obtain a single component with uniform molecular weight distribution and purity ≥ 95%.

Embodiment 3

[0025] In a 100-liter fermenter, inoculate Cordyceps militaris, the inoculum amount is 8%, the amount of the fermenter medium is: 60 liters, according to the medium yeast extract powder 1%, brown sugar 2.0%, male silkworm moth oil 3%, KNO 3 0.88%, MgSO 4 0.15%, KH 2 PO 4 0.15% formula, static culture for 7 days. The obtained culture solution is filtered with ordinary filter paper, the filtrate is centrifuged at 12000rmp / min, and the filtrate is filtered with a 0.22 μm filter membrane, and the filtrate is continuously filtered with an ultrafiltration membrane with a molecular weight of 0.5 million Daltons, and the molecular weight cut-off value is 1, 5. 1. Different ultrafiltration membranes of 100,000 Daltons are used to concentrate the obtained filtrate by graded high-pressure ultrafiltration, and vacuum freeze-dry the obtained intercepted concentrated solution to obtain a single component with uniform molecular weight distribution and purity ≥ 95%.

[0026] Beneficial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com