Switching optical fibre laser on frequency

A fiber laser and frequency technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as difficult, unstable work, large volume, etc., and achieve high efficiency and multiple laser output wavelengths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

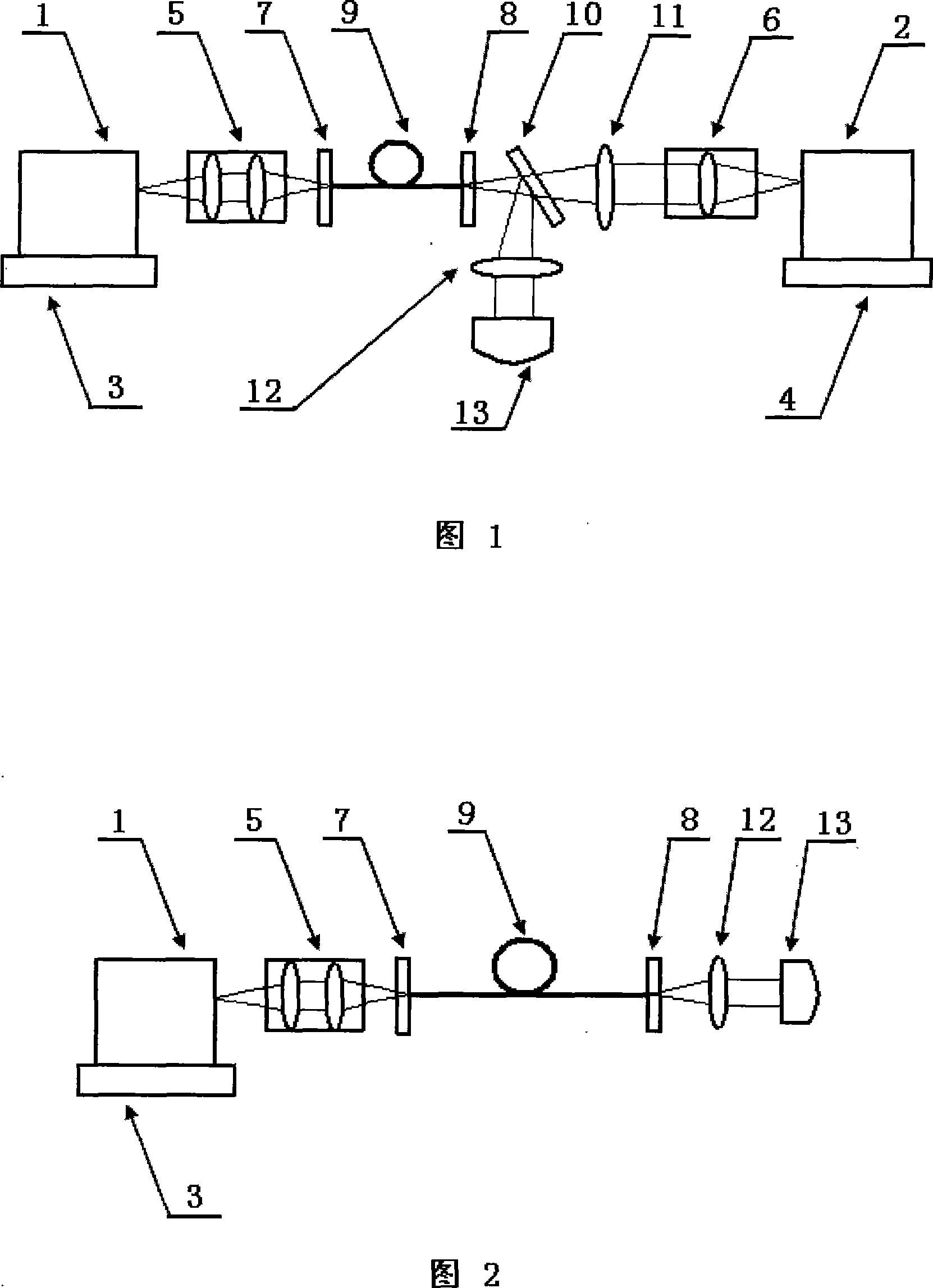

[0023] Fig. 1 is one of the structural schematic diagrams of the frequency up-conversion fiber laser of the present invention. Among them, the pump source 1 is a semiconductor laser with an output wavelength of 976nm. The pump laser is focused into a section of Er / Yb co-doped germanate glass double-clad optical fiber through the collimating and focusing lens group 5; the pump source 2 is A semiconductor laser with an output wavelength of 803nm, the pump laser passes through the collimating lens group 6, and then is focused into the optical fiber through the focusing lens 11. The focal length of the focusing lens 11 is 5 cm, so that the dichroic beam splitter 10 is as close as possible to the output coupling mirror 8 . The input coupling mirror 7 is a flat dichroic mirror with high transmission to the 976nm pump laser and high reflection to the 545nm signal laser. Transmitting and highly reflecting the output 545nm signal laser, the output coupling mirror 8 is a plano-concave ...

Embodiment 2

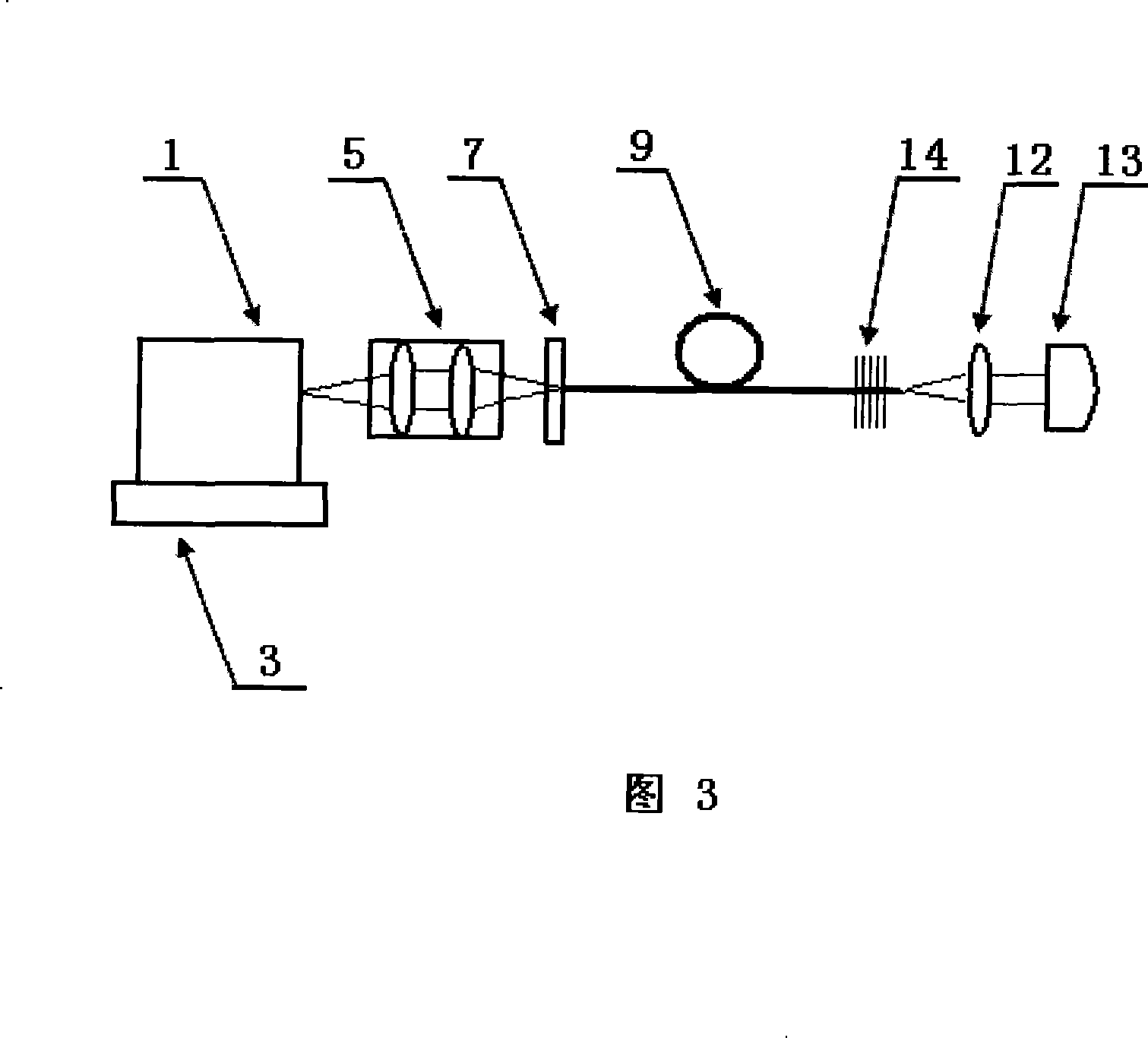

[0027] The present invention can also adopt the solution of unidirectional pumping, as shown in FIG. 2 . It includes: pumping source 1, temperature control system 3, collimating and focusing lens group 5, input coupling mirror 7, output coupling mirror 8, rare earth doped optical fiber 9, collimating mirror 12, and detection system 13. The relationship between the components is: the pumping source 1 stably outputs the pump laser light through the temperature control system 3, and after being focused by the collimating and focusing lens group 5, it is coupled into the rare earth-doped optical fiber 9 through the input coupling mirror 7. The input coupling The contact end faces of the mirror 7 and the rare-earth-doped optical fiber 9 should be close to each other, and the generated visible light (especially blue-green light) laser part passes through the output coupling mirror 8 and enters the detection system 13 after being collimated by the collimating mirror 12 .

[0028] Whe...

Embodiment 3

[0030] The present invention uses a fiber Bragg grating as a solution for the output coupling mirror, as shown in FIG. 3 . It includes: pumping source 1, temperature control system 3, collimating and focusing lens group 5, input coupling mirror 7, fiber Bragg grating 14, rare earth doped optical fiber 9, collimating mirror 12, and detection system 13. The relationship between the components is: the pumping source 1 stably outputs the pump laser light through the temperature control system 3, and after being focused by the collimating and focusing lens group 5, it is coupled into the rare earth-doped optical fiber 9 through the input coupling mirror 7. The input coupling The contact end faces of the mirror 7 and the rare-earth-doped optical fiber 9 should be close to each other, and the generated visible light (especially blue-green light) laser part passes through the fiber Bragg grating 14 and enters the detection system 13 after being collimated by the collimating mirror 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com