Pressure-sensitive adhesive optical film and image display

An optical film and adhesive technology, applied in optics, optical components, identification devices, etc., can solve problems such as unevenness and inability to eliminate window frames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

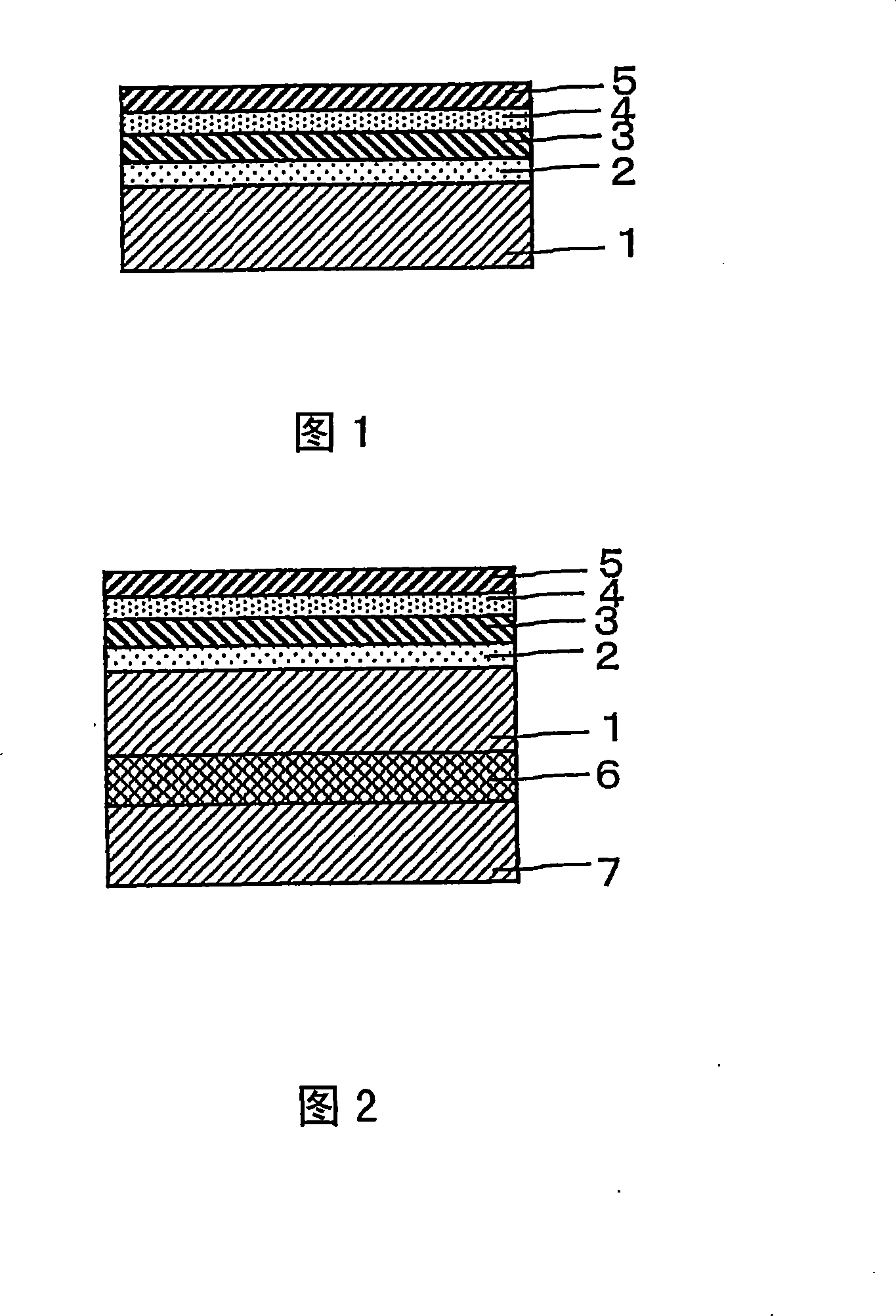

Image

Examples

Embodiment 1

[0132]

[0133] As the matrix polymer, an acrylic polymer having a weight-average molecular weight of 1.65 million (as polymerized As an initiator, a solution (15.5% of solid content) of 0.3 parts of 2,2'-azobisisobutyronitrile) was used per 100 parts of monomers. To 100 parts of the solid content of the above-mentioned acrylic polymer solution, 0.3 parts of dibenzoyl peroxide (manufactured by NOF Co., Ltd., Nippa BMT40SV), 0.02 parts of trimethylolpropane di Toluene diisocyanate (manufactured by Mitsui Takeda Chemical Co., Ltd., Takenet D110N), 0.2 parts of acetoacetyl group-containing silane coupling agent (manufactured by Soken Chemical Co., Ltd., A-100), and a binder solution (solid content 12%).

[0134]

[0135] Using the reverse roll coating method, the obtained adhesive solution was applied on a release sheet made of a polyester film (thickness: 38 μm) that had been subjected to mold release treatment so that the thickness of the adhesive layer after drying was 20...

Embodiment 2~7

[0145] In Example 1, except having changed the compounding quantity of the phenolic antioxidant as shown in Table 1 when preparing a tackifier, it carried out similarly to Example 1, and produced the adhesive type optical film.

Embodiment 8

[0147] In Example 1, when preparing the tackifier, as the antioxidant, a phenolic antioxidant (manufactured by Chiba Special Chemicals Co., Ltd., Ilganox 1010) and a phosphorus-based antioxidant (manufactured by Chiba Special Chemicals Co., Ltd. , イルガノツックス B225), with the ratio of phenolic antioxidant: phosphorus antioxidant = 1:1 (weight ratio), their total relative to the solid content of the solution 100 parts, add 1 part, in addition, It carried out similarly to Example 1, and produced the adhesive type optical film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com