Shadow mask type plasma display board foreplate and manufacturing method therefor

A plasma and manufacturing method technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of reducing dyeing effect, yellowing, etc., to reduce dyeing effect, eliminate yellowing, weaken The effect formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

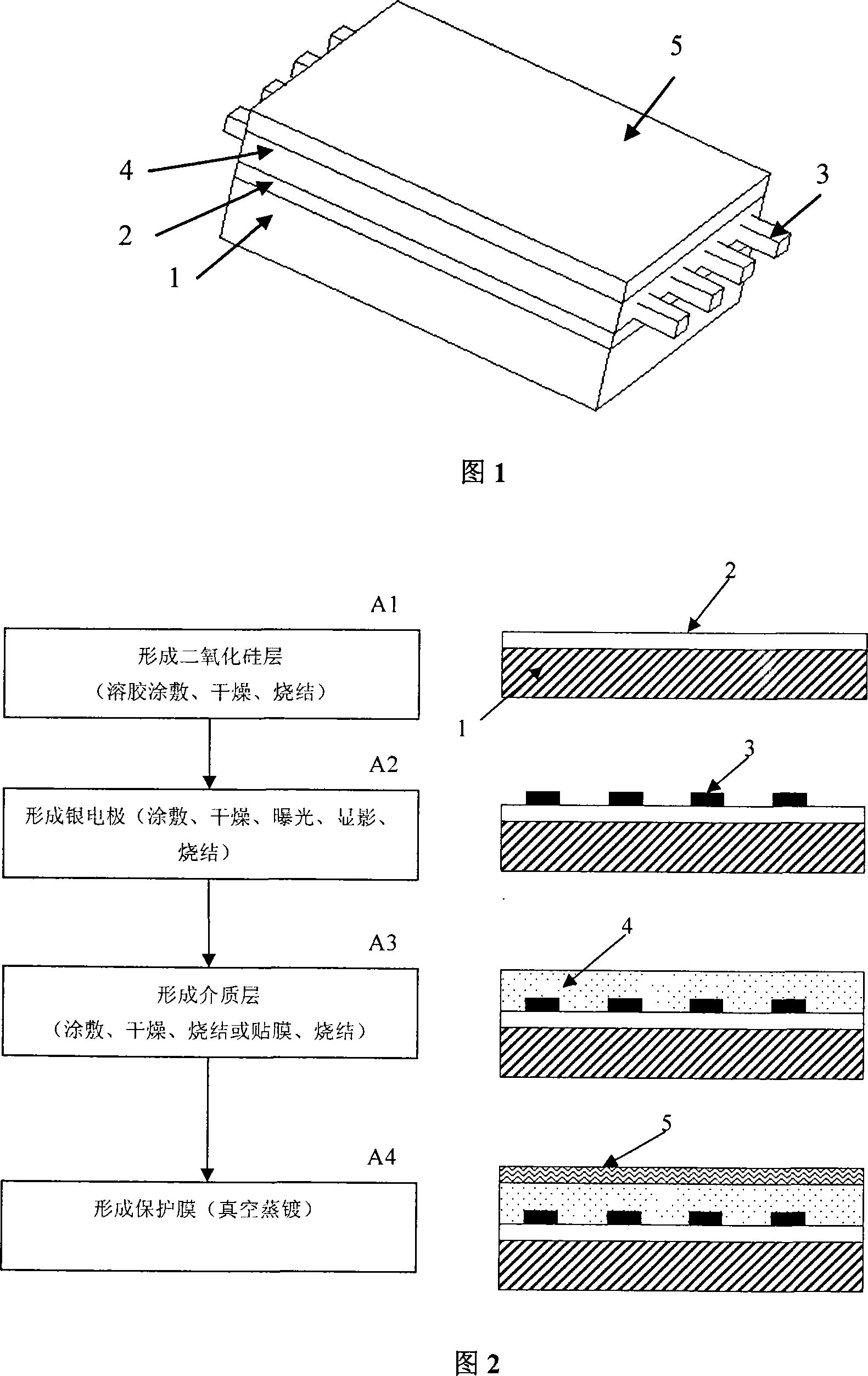

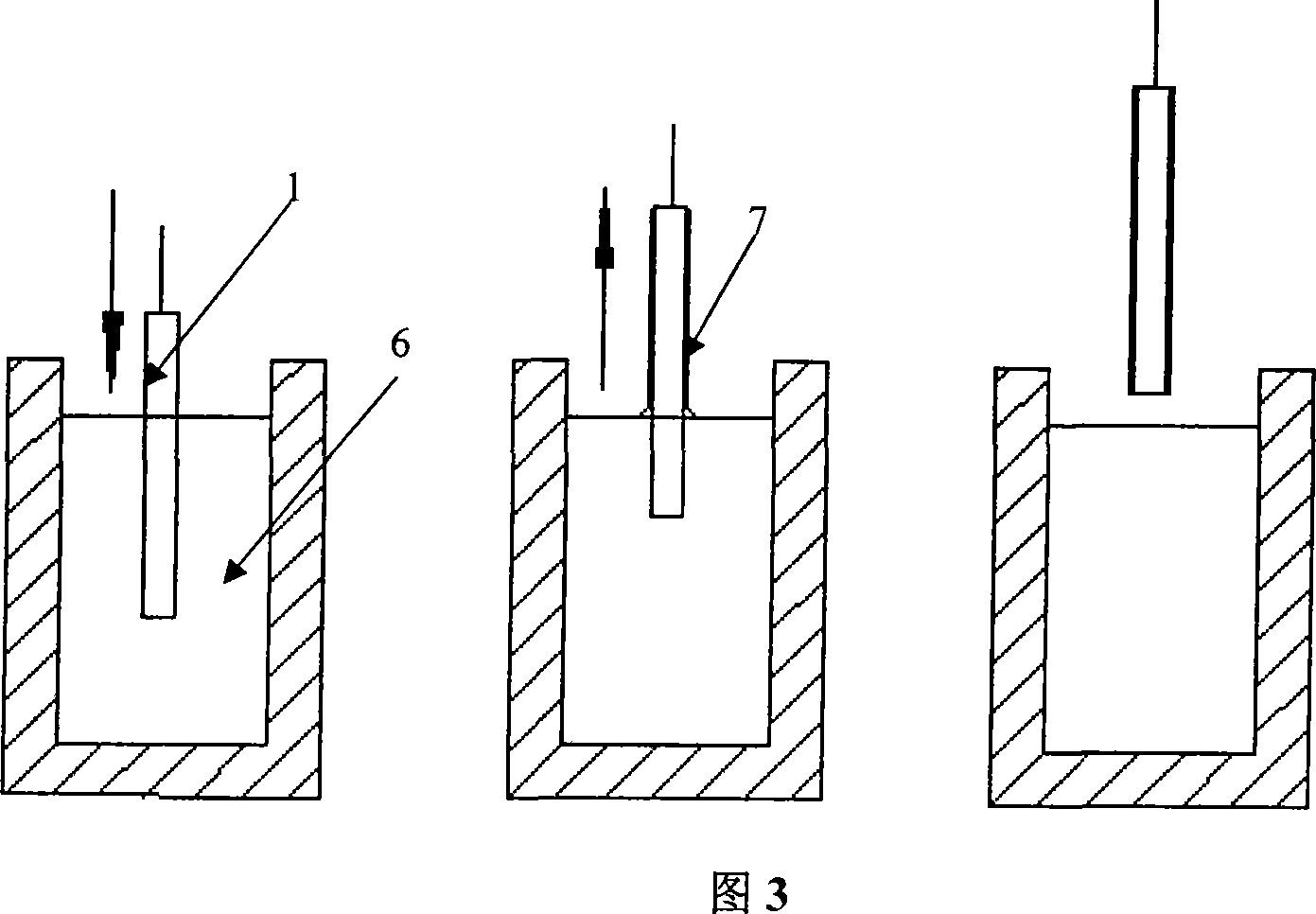

[0024] As shown in Figure 1-3.

[0025] A front plate of a shadow mask type plasma display panel comprises a glass substrate 1 as a front substrate, a silicon dioxide layer 2, a silver electrode 3, a dielectric layer 4 and a protective film 5. The silicon dioxide layer 2 is located between the glass substrate 1 and the silver electrode 3, and its thickness is greater than 10 μm, which is used to prevent the silver in the electrode from diffusing to the surface of the glass substrate during the whole process of making the glass front plate. The silicon dioxide layer 2 is coated on the tin-free surface of the glass substrate 1 as the front substrate, the dielectric layer 4 is covered on the silver electrode 3, and finally the dielectric layer 4 is covered with a protective film 5, as shown in Figure 1 .

[0026] Next, the method of manufacturing the fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com